Command: enter pressure/force control (time) (45), Enter pressure/force control (time) (45), R enter pressure/force control (time) (45) – Delta RMC151 User Manual

Page 815

8 Command Reference

8.5.1.7. Command: Enter Pressure/Force Control (Time)

(45)

Supported Axes: Pressure/Force Control Axes

Firmware Requirement: 2.50 or newer

Hardware Limitations: RMC75S: versions 2.1D or newer only

RMC75P: versions 2.1E or newer only

RMC75E: No limitations

RMC150E: No limitations

See the Commands Overview topic for basic command information and how to issue

commands from PLCs, HMIs, etc.

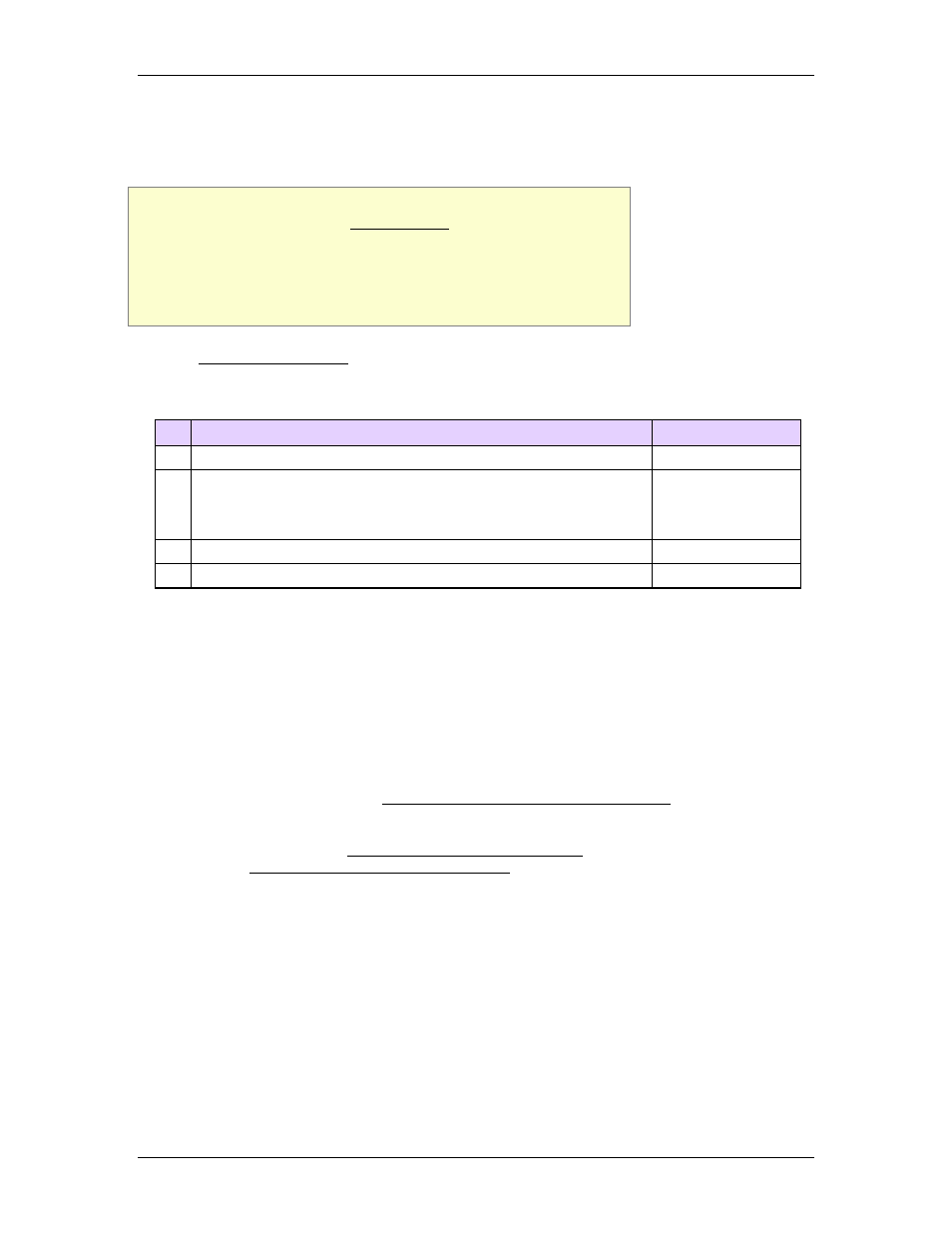

Command Parameters

# Parameter Description

Range

1 Requested Pressure/Force (Pr or Fr)

any

2 Ramp Type

•

Linear (0)

•

S-curve (1)

A valid integer as

described

3 Time for Ramp (sec)

≥ 0

4 Integrator Preload (%)

-100% to 100%

Description

This command enters pressure or force control and then ramps to the requested

Pressure or Force in the specified Time for Ramp. A Linear Ramp Type will ramp the

pressure or force linearly until it reaches the Requested Pressure/Force. An S-curve

Ramp Type will provide a half s-curve ramp to the Requested Pressure/Force.

Upon entering pressure or force control, the Target Pressure or Target Force will be set to

the Actual Pressure or Actual Force. The Target Pressure or Target Force will then be

ramped to the Requested Pressure/Force in the specified Time for Ramp.

This command may cause the pressure/force rate to change suddenly at the transition, as

shown in the plot in the example below. If this is a problem, try using a shorter Time for

Ramp, or consider using the Enter Pressure/Force Control (Auto) (44) command, which

will automatically ramp at the current Actual Pressure/Force Rate (depending on the

tuning), eliminating the sudden change in rate. Another option is to create a user

program that issues the Hold Current Pressure/Force (19) command, then immediately

issues the Ramp Pressure/Force (S-Curve) (41) command.

The Integrator Preload specifies the value that the Integral Output Term should be set

to when transitioning into pressure/force control. The Preload is specified as a percentage

of the Output Scale (typically 10V), and is not affected by the pre-transition integrator

state. Typically, this can be left at the default value of 0. If the pressure/force exhibits a

drop upon entering pressure/force, increase this value to help smooth the transition.

Example

Consider a hydraulic press that must move toward the material to be pressed, transition

to pressure control and hold a certain pressure.

The user program below shows a possible sequence of steps.

Step 0 issues a Move Absolute command to move the axis to a position beyond where it

expects to encounter the material. The Step 0 Link Type waits for the Actual Pressure to

exceed 1000, then it goes to Step 1 which issues an Enter Pressure/Force Control (Time)

deltamotion.com

795