Handling broken profinet connections, E handling broken profinet connections – Delta RMC151 User Manual

Page 496

RMC70/150 and RMCTools User Manual

In order to allow users to read and write registers in the RMC starting at locations other

than the beginning of a register file, the RMC defines four Custom Data Records, which

are addressed as Slot 0, Subslot 1, and Index 1000-1003:

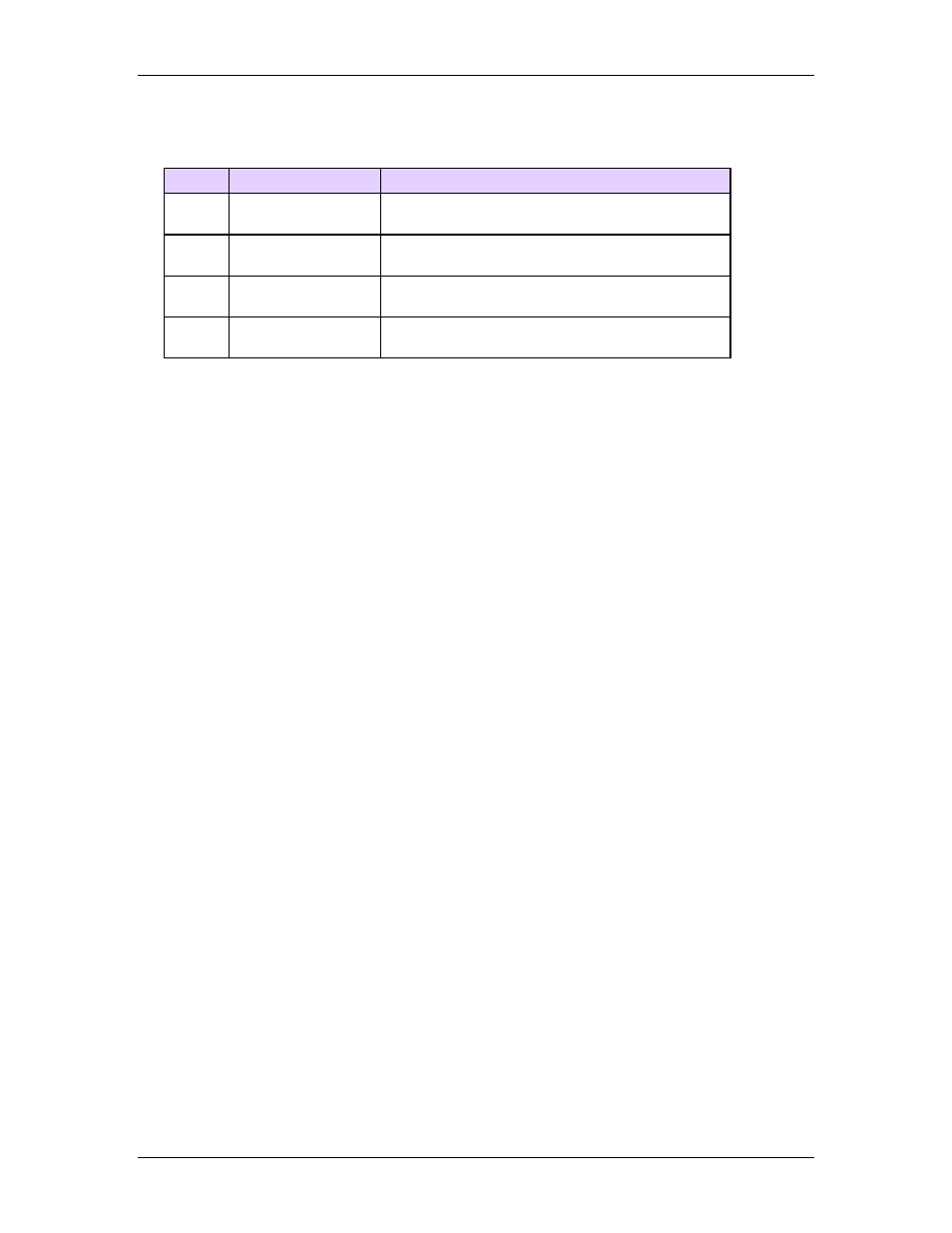

Index

Starting Address

Description

1000

Configurable

The starting address is configurable in

RMCTools.

1001

Configurable

The starting address is configurable in

RMCTools.

1002

Configurable

The starting address is configurable in

RMCTools.

1003

Configurable

The starting address is configurable in

RMCTools.

The starting addresses of each of the Custom Data Records are set up in the PROFINET

Settings Page.

For example, to read or write a block of registers starting at variable 50 (%MD56.50), the

user can set Custom Data Record 1000 to have a starting address of %MD56.50, and

then read or write to Index 1000.

PROFINET-specific Record Data

In addition to the user data records described above, the RMC also supports PROFINET-

specific data records as defined in the PROFINET standard. These records are generally

only of interest to the PROFINET configuration software. They have Index values in the

range of 0x8000-0xFFFF. Refer to the PROFINET specification for details.

Record Data Format and Length

The contents of the Fixed and Custom Data Records match the contents of the

corresponding RMC registers. Therefore, each register will be a 32-bit (4-byte) DINT,

DWORD, or REAL data value. However, be aware that the MLEN and LEN parameters on

the RDREC and WRREC function blocks are in bytes. Therefore, these values must be 4x

the number of registers you want to read or write. By default each 32-bit value is

transmitted most-significant byte first, which should work for most IO controllers.

Otherwise, the byte order can be changed to least-significant byte first on the PROFINET

Settings Page.

The format and length of the PROFINET-specific data records are defined in the PROFINET

standard.

6.8.10.7.5. Handling Broken PROFINET Connections

It is important in many industrial applications to detect faults quickly. One such fault is losing

PROFINET I/O communication. PROFINET supports a configurable timeout value, which is

expressed in terms of a multiple of the update time. The default multiplier is 3 for most IO

Controllers. For example, for an update time of 16 ms and a timeout multiplier of 3, the

connection timeout will be 3 x 16 ms or 48 ms.

When either the IO-Controller or IO-Device does not receive a packet from the other device

for the timeout interval, it closes the connection and typically indicates this condition to the

main program. The method of indicating this condition depends on the actual device. This

topic describes the methods used by the RMC and STEP7.

Handling Broken I/O Connections in the RMC

The RMC has tags that indicate the state of the controlling connection. The user can use

these registers to qualify whether certain operations in the User Programs can be done,

or they can use these registers in the Program Triggers to respond to the change in state

476

Delta Computer Systems, Inc.