Delta RMC151 User Manual

Page 118

RMC70/150 and RMCTools User Manual

The ultimate goal of the cascaded loops is to control the end process. Cascade control can

provide precise control for certain difficult systems, for example systems in which some

lag time exists.

To better understand cascade control, consider the following example in hydraulic motion

control:

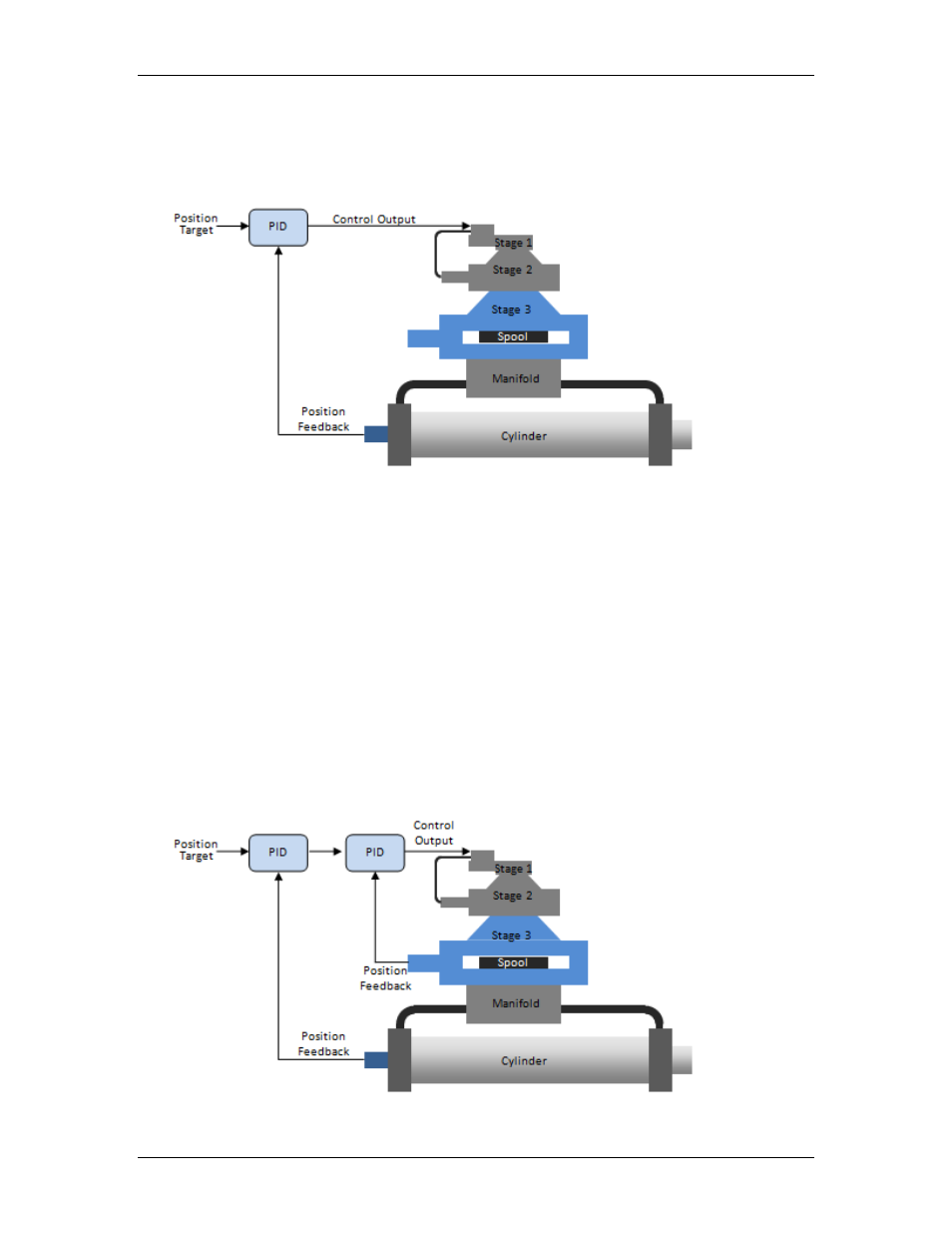

The figure above shows a very large hydraulic cylinder with a 3-stage proportional valve.

The goal is to control the cylinder position.

The first two valve stages have internal electronic controls, and all we need to know

about them is that the first two stages will produce a velocity on the third stage that is

roughly proportional to the Control Output signal received by the valve. The third stage

has no electronic controls.

A standard PID control loop can be applied to this system, as shown in the figure.

However, this results in poor control. The valve spool responds very quickly compared to

the cylinder. Therefore, when the Position Target of the system (the desired position of

the cylinder) changes, the valve spool will immediately move over its full length of travel,

while the cylinder has barely begun moving, and when the actual position eventually

catches up to the target, the spool will immediately move back the full length, and in that

way, the system can begin to oscillate and will result in poor control.

A better method is to apply an additional inner PID loop to the valve in a cascaded

configuration, as shown in the figure below. This requires spool position feedback from

the third stage of the valve. The valve will then provide a much more linear flow in

relation to the Control Output, which will make the outer position PID much easier to tune

and will provide better control.

Cascade Control Advantages

98

Delta Computer Systems, Inc.