Command: sine start (72), Sinusoidal, Sine start (72) – Delta RMC151 User Manual

Page 774

RMC70/150 and RMCTools User Manual

This command specifies a profile in terms of speed versus position. The RMC compares

the current Target Position with the Requested Position and computes a target profile

that reaches the Requested Velocity at the Requested Position. Once the Requested

Position (and therefore Requested Velocity) is reached, the Done status bit will be set.

If the Requested Velocity was non-zero, the target generator will continue at the final

Requested Velocity indefinitely. This command is a closed loop control command.

Notice that it is difficult to determine exactly how long the move will take. This command

will attempt to move the axis using the shortest path possible and will attempt to make

the Target Acceleration non-zero during the entire move.

If the Requested Position is behind the Actual Position at the time this command was

issued, a Command Error or Runtime error will be set. "Behind" refers here to being in

the direction opposite to the current direction of travel. Similarly, if the axis is stopped,

the Requested Velocity must be positive if the Requested Position is greater than the

current position, and negative if the Requested Position is less than the current

position.

Why Bother?

This command is good when you want to specify the ends, not the means. There are two

applications where this really works well:

•

When you suddenly want to stop at a certain position, but do not know what

deceleration rates you need. Maybe you usually use a deceleration of 100 in/s

2

, but if

the axis is travelling fast close to the position where you want to stop, the decel rate

of 100 might not be enough to stop you fast enough. If you issue a Speed at Velocity

(36) command with a Requested Velocity of zero, the RMC will calculate the

deceleration for you and will get you stopped at the requested position. Note that if

you issue this command a long distance before you stop, the calculated decelerations

may be so low that it takes a long time to stop.

•

Injection molding applications often specify the speed relative to the position. You can

set up a user program that issues this command for each trigger point, and it will go

to the Requested Velocity at the position.

Target Generator State Bits

The Target Generator bits in the Status Bits register indicate which portion of the move

the axis is currently in. These bits are useful when programming complex motion

sequences.

Target Generator Done bit

This bit indicates the move is complete, which occurs when the Target Position has

reached the Requested Position.

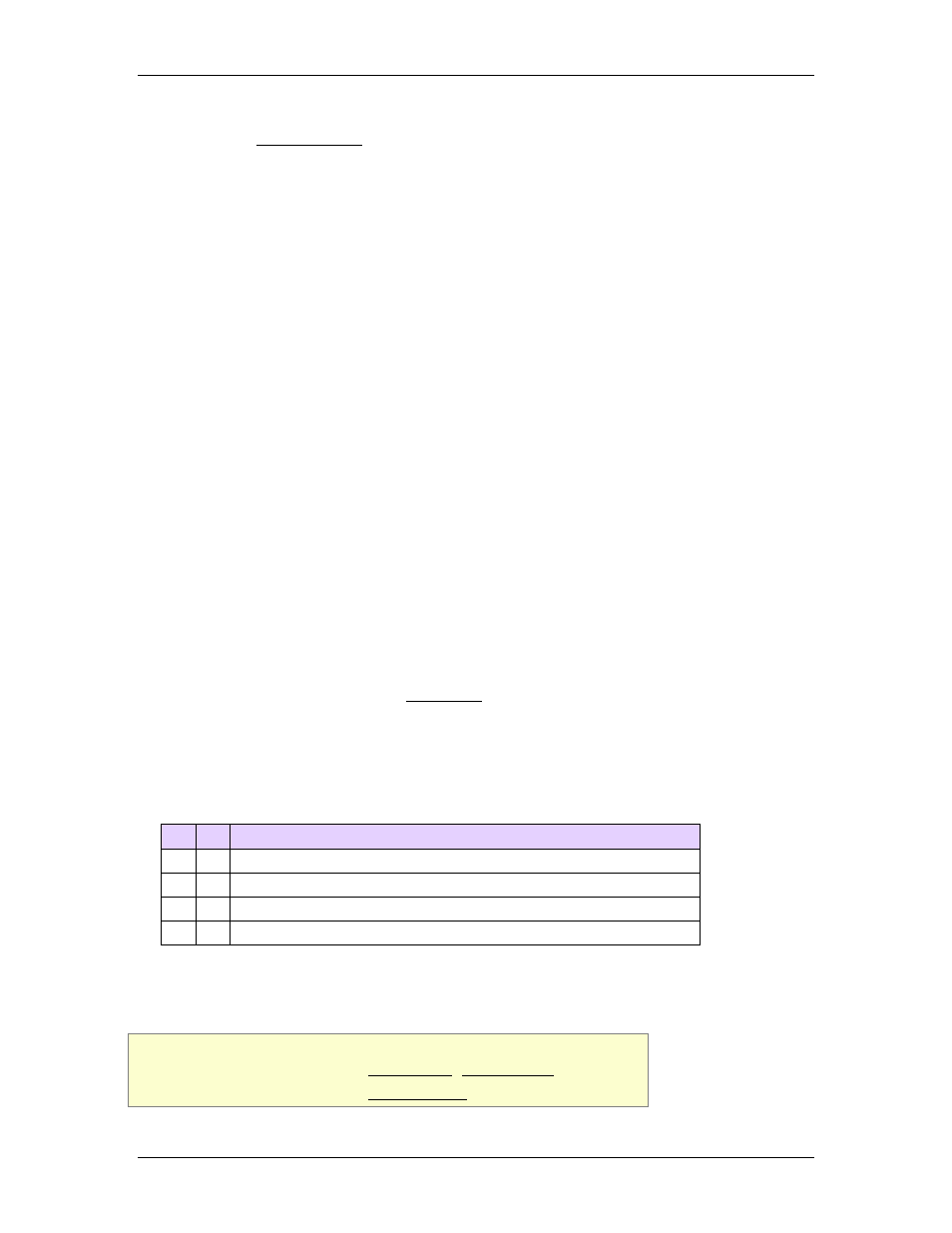

Target Generator State A and B bits

B

A Description

0

0

The target generator is complete

0

1

Acceleration

1

0

Constant Velocity

1

1

Deceleration

8.4.7.2. Command: Sine Start (72)

Supported Axes: Position Control Axes

Supported Control Modes: Position PID, Position I-PD

Firmware Requirement: 2.30 or newer

754

Delta Computer Systems, Inc.