Delta RMC151 User Manual

Page 165

3 Controller Features

Notice if you wish to be able to save the curve to Flash, you should choose the

Permanent Life Cycle option. Only curves created with the Permanent Life Cycle option

or downloaded from the Curve tool can be saved to Flash.

After the Curve Add (82) command has been added the curve, the data in the Variable

Table is no longer needed. You can, for example, use it to add additional curves.

4. Wait for the Curve Status to be 3

Wait for the Curve Status to be 3. This indicates that the RMC has completed processing

the curve data and has created the curve. The Curve Status is the first item you

entered in the curve data in the Variable Table. Notice that you will need to look in the

Monitor tab of the Variable Table Editor to see the real-time value.

If the Curve Status changes to a value of 10 or greater, it indicates an error. See the

Curve Status Error Codes topic for a list of possible error values.

If you are using the Curve Add (82) command in a user program, you should make a

Link Type that waits for the Curve Status to be 3 before continuing. The Curve Status

will be the Current Value of the first variable in the curve data you entered in the

variable table. In this example, it would be variable 10. You can assign a tag name to

variable 10 to make it easier to find.

5. Move the axis to the first point.

Before you can follow the curve, the Target Position (Target Pressure or Force) of the

axis must be at the first Y-axis position of the curve, which is 1.0 in this example. This

can be done by using a Move Absolute command to move the axis to 1.0. For following

a pressure or force curve, you will need to move the Target Pressure/Force to the first

point’s Y value.

Notice that you can move the axis to the first point before the Curve Status is 3.

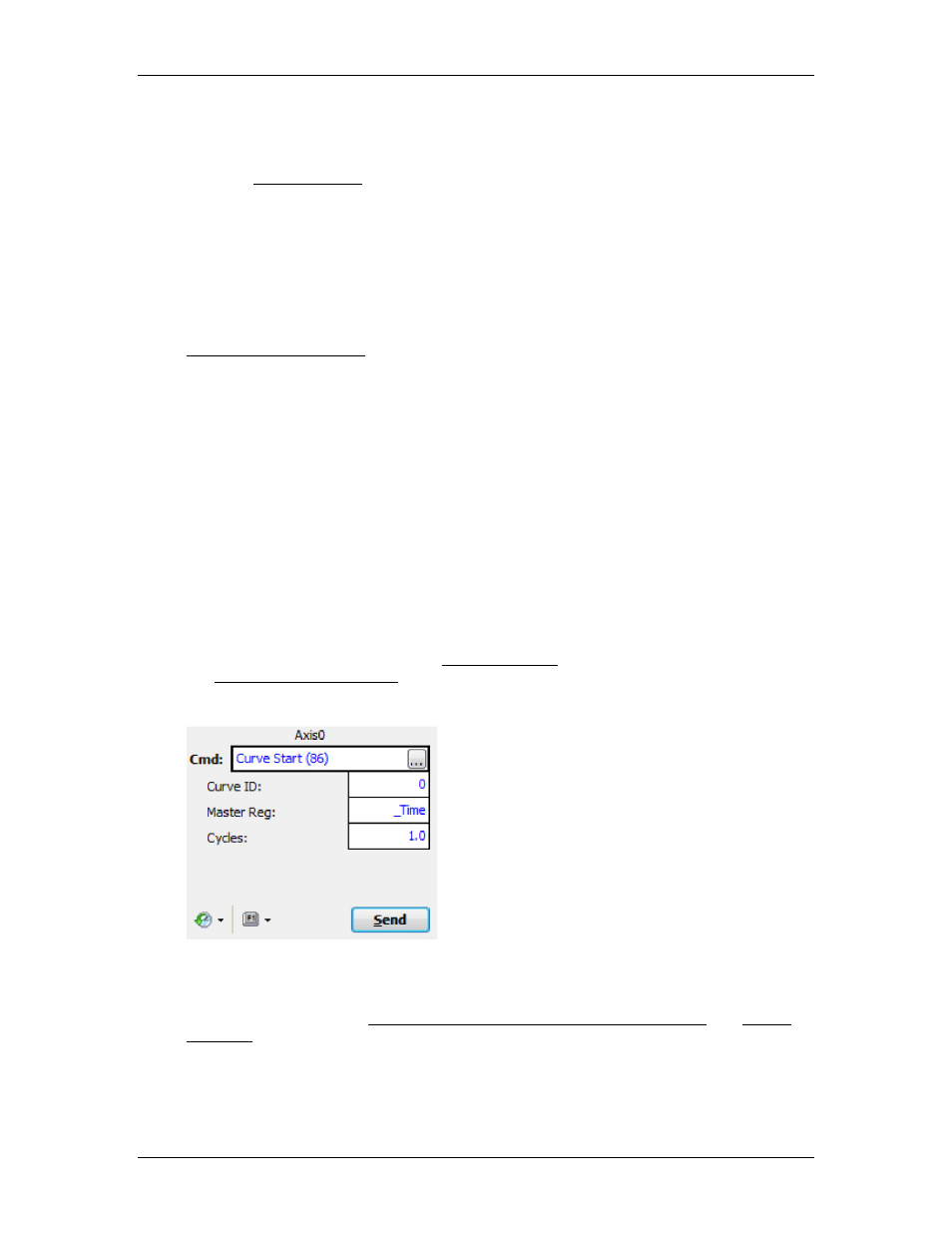

6. Send the Curve Start Command

To start following a curve, send the Curve Start (86) command for a position curve, or

the Curve Start (Prs/Frc) (87) command for a pressure or force curve. If the axis is not

at the first point of the curve, an error will result and the curve will not start.

This command will start curve 0, will follow it based on time, and will follow it once.

For more details, see the Creating Curves Using the Curve Add Command and Curves

Overview topics.

Tips for Using Curves from a PLC or HMI

deltamotion.com

145