Delta RMC151 User Manual

Page 757

8 Command Reference

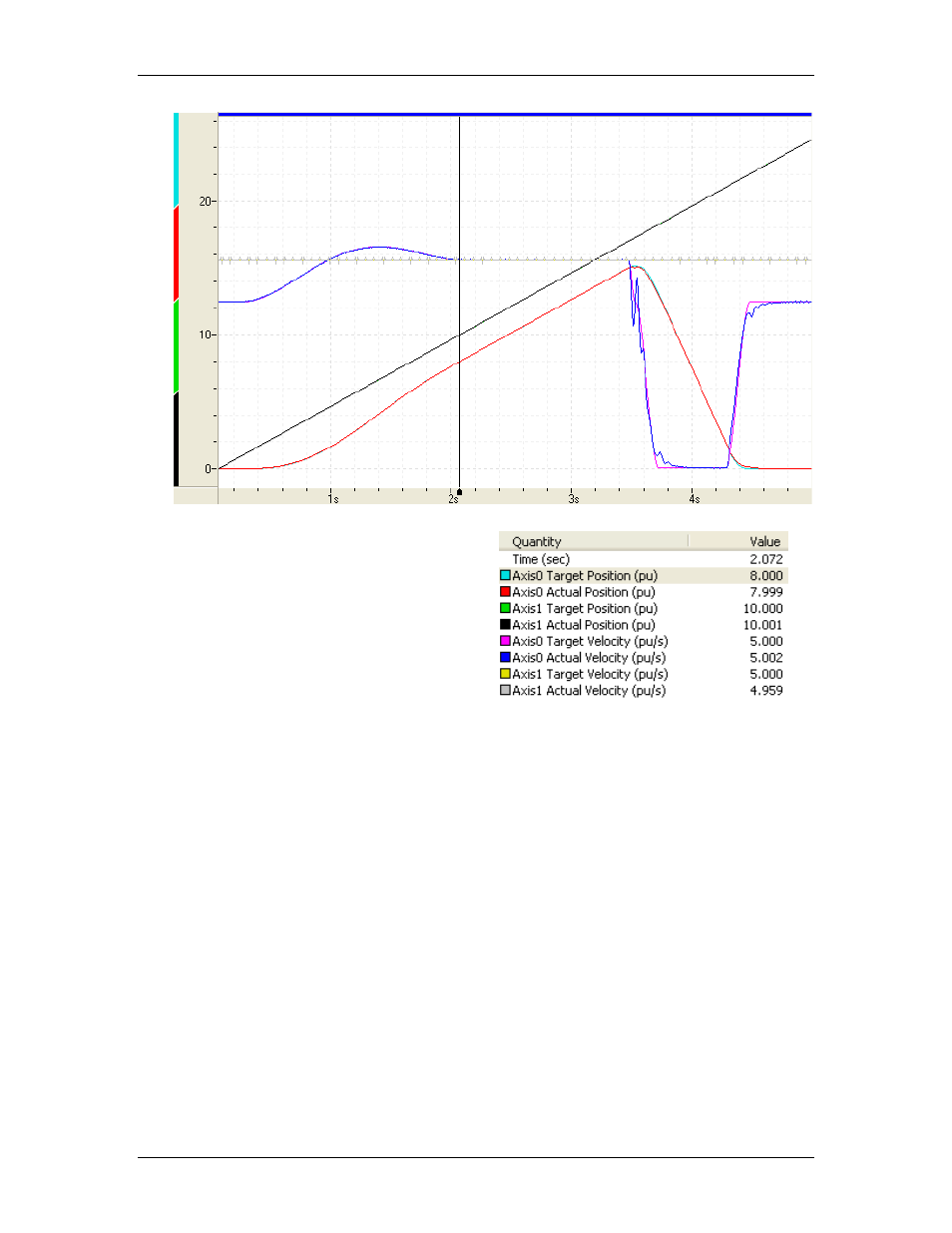

The plot shows Axis 1 (the master)

moving at a constant 5 in/sec. The

carriage (Axis 0) is stopped, then

accelerates to catch up to the master.

Axis 0 and Axis 1 Target Positions are

synchronized at 8 and 10, as indicated

by the legend to the right. The legend

indicates the values at the cursor in the

plot.

In the plot, the axes remain

synchronized (while the system is

cutting) until approximately 3.5

seconds, at which point a command

was issued to move the carriage back

to its home position. This return move

can be done with a Move Absolute, or

even the Gear Pos (Clutch by Distance)

command.

Plot Legend

Master Start Distance Details

The Master Start Distance specifies how far from the Master Sync Position the

clutching should start. This position is called the Master Start Position. When the

master reaches this position, the slave axis begins moving. This section describes how the

Master Start Distance affects the motion and cases in which the RMC modifies the

Master Start Distance.

If the Slave is Initially Stopped or Geared at a Zero Ratio

The distance from the Slave Start Position (slave position at the time the command is

issued) to the Slave Sync Position is called the Slave Distance. If the slave is stopped

or geared at a ratio of zero when this command is issued, and the Master Start

Distance is greater than (2.5 x Slave Distance / Final Gear Ratio), then the Master

Start Distance will be reduced to (2.5 x Slave Distance / Final Ratio). This behavior is

due to the mathematical formula used to calculate the profile. Without this behavior, the

profile might move in the wrong direction first. Notice that after the command is issued,

deltamotion.com

737