Delta RMC151 User Manual

Page 755

8 Command Reference

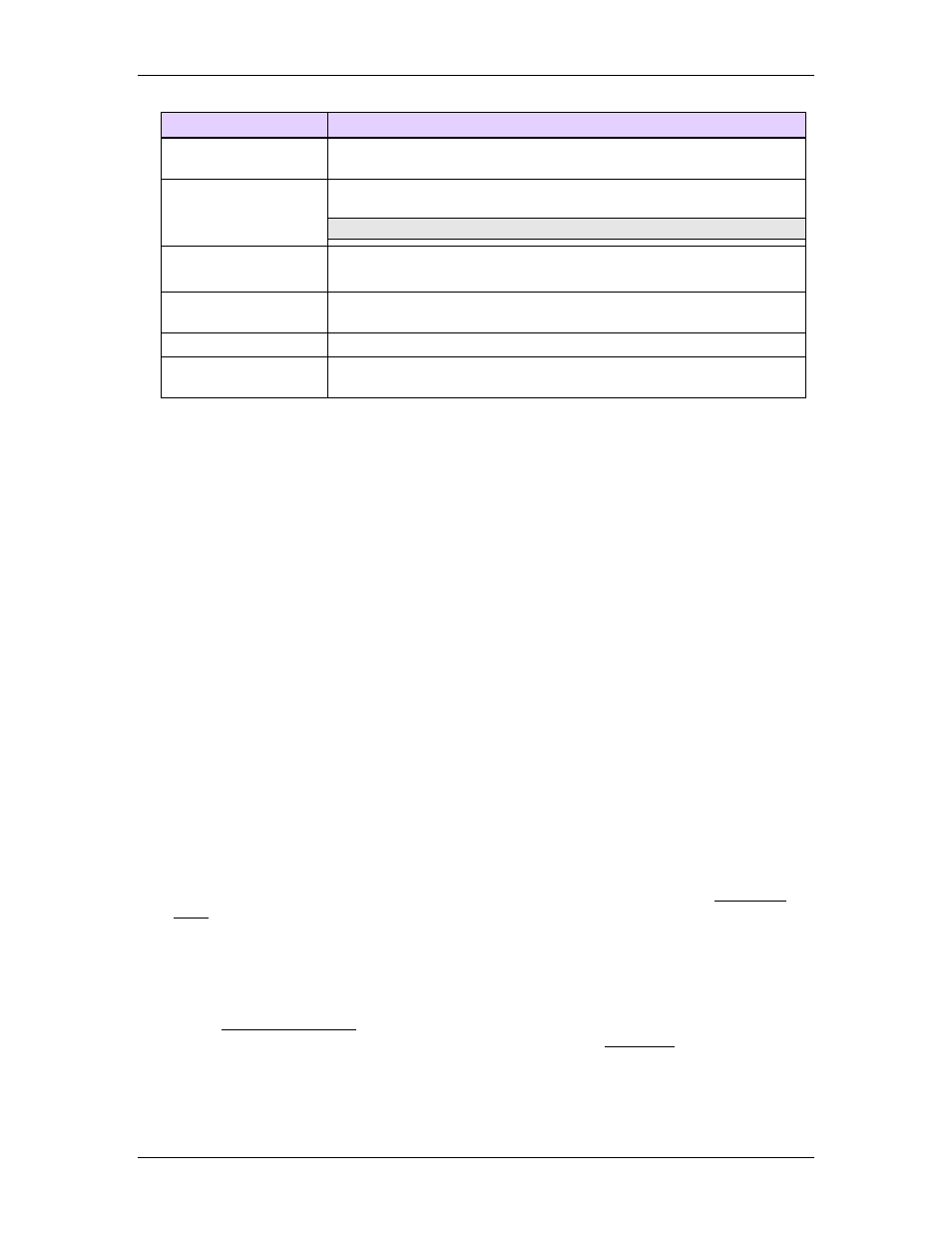

Term

Description

Master Sync

Position

The position of the master at which the slave will be at its sync

position and will be at locked in at the final gear ratio.

Master Start

Distance

The distance from the Master Sync Position during which the

clutching will take place. This area is also called the "clutch area".

Note: This is the distance, not the absolute position!

Master Start

Position

The master position at which the slave starts clutching.

This position is Master Sync Position - Master Start Distance.

Slave Sync Position The position of the slave at which the master will be at its sync

position and the slave will be at locked in at the final gear ratio.

Slave Start Position The slave position at the time the command is issued.

Slave Distance

The distance between the Slave Start Position and the Slave Sync

Position.

Clutching

This command requires that the slave is either stopped (which is a zero gear ratio) or

geared when the command is issued. This gear ratio will be used to create an initial

constant gear ratio that holds until the master reaches the Master Start Position.

When the master moves beyond the Master Start Position, the gear ratio will ramped

from the initial ratio to the requested ratio such that the two synchronize exactly at the

requested Master Sync Position and Slave Sync Position. The Master Start

Distance specifies how far from the Master Sync Position the clutching should start.

The Master Start Distance implies the direction with its sign. For example, with a

Master Sync Position of 10, a Master Start Distance of 2 means that the clutching

happens as the master moves from 8 up to 10. With a Master Sync Position of 10, a

Master Start Distance of -2 means that the clutching happens from 12 down to 10.

Notice that the RMC will decrease the Master Start Distance in some cases. See the

Master Start Distance Details section below for more details.

Reversing Direction

This command allows reversing the direction of the master. If the master reverses

directions before the axes have reached the sync positions, the slave will follow the

profile in reverse. If the master continues in reverse past the Master Start Distance, the

slave will continue following the master in reverse using the initial gear ratio. The

clutching will resume if the master returns to the Master Start Position.

Once the axes have reached the sync positions, the slave will lock in at the final gear

ratio, and will gear to the master at that ratio whether the master goes forward or

backward. It will not revert to the profile it followed before reaching the sync position.

Errors

If the axis is not stopped or already geared when this command is issued, a Command

Error will be generated.

If the Master Position is already beyond the Master Sync Position when the command is

issued (where "beyond" is defined by the direction implied by the Master Start Distance

as described above), then the command will fail with a Command Error.

If the Master Position is already in the clutch area (between Master Start Position and

Master Sync Position) when the command is issued, then the command will proceed but

with a Command Modified error, since the effective Master Start Distance will be adjusted

to make the move complete. Setting the Command Modified Auto Stop to Status Only will

allow this move to proceed.

Uses for Gear Pos (Clutch by Distance) Command

The Gear Pos (Clutch by Distance) command is useful for the following purposes:

deltamotion.com

735