Delta RMC151 User Manual

Page 62

RMC70/150 and RMCTools User Manual

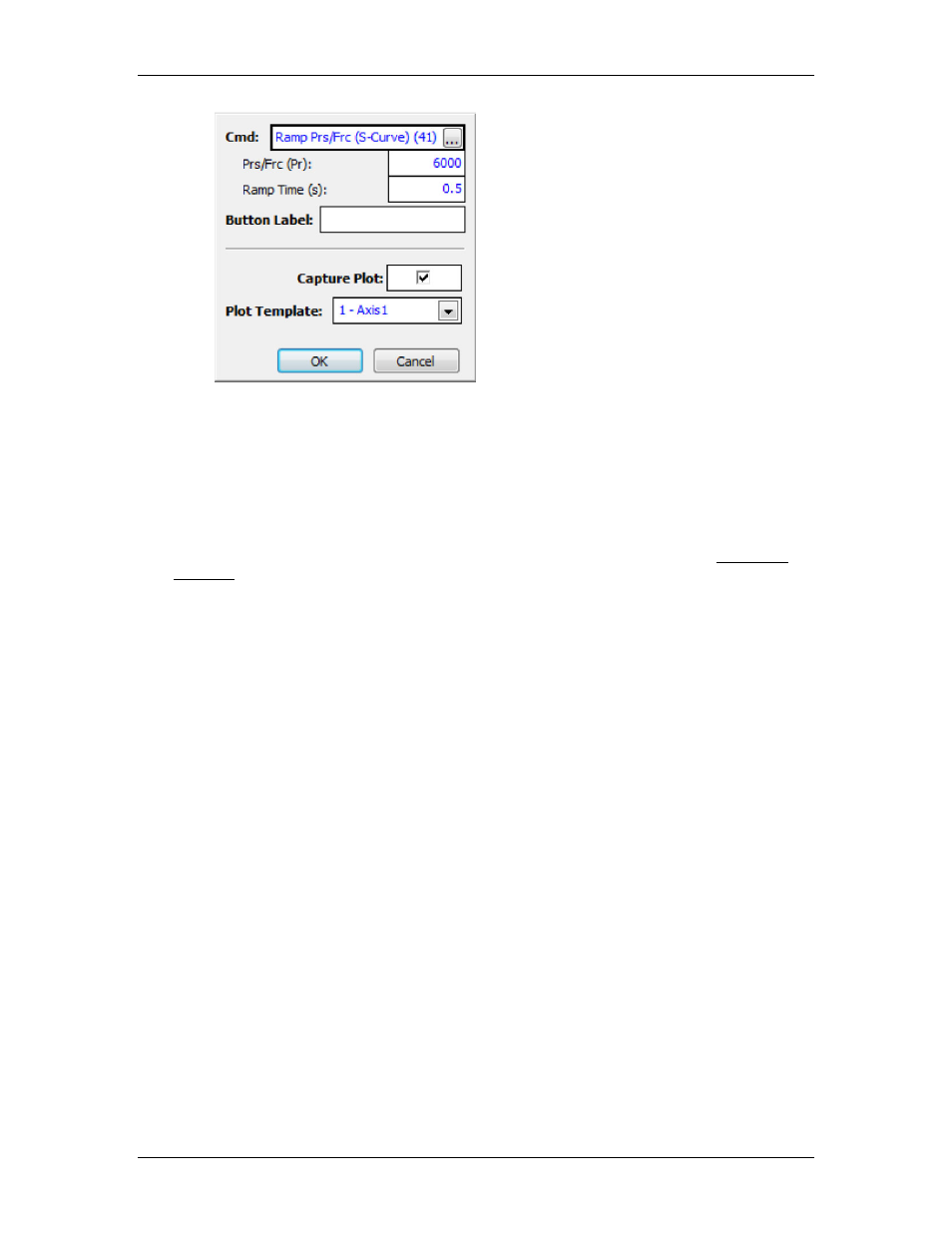

c. Repeat the previous step for the other command button, and enter a different value

for the Pressure/Force.

Tuning Steps:

1. Enter Pressure/Force Control

Set the Pressure/Force Proportional Gain to a small value, such as 0.01.

In the Tuning Tools, on the Pressure/Force tab, click the Hold Prs/Frc button to enter

pressure/force control. Then click one of the buttons you set up to ramp the Command

Pressure to the desired value.

You may wish to move the axis in open loop to where it encounters pressure/force before

you click the Hold Prs/Frc button.

If the axis halts due to an Output Saturated error, reduce the Proportional Gain and

repeat.

2. Adjust the Proportional Gain

Start with a small value. If the application is a hydraulic cylinder controlling force in

pounds, a typical starting value may be 0.01 or smaller.

In the Tuning Tools, on the Pressure/Force tab, notice that the Target

Pressure/Force and Actual Pressure/Force are displayed.

Keep increasing the Proportional Gain until the Actual Pressure/Force starts moving

toward the Target Pressure/Force. It should not get all the way toward to Target

Pressure/Force. Give just enough gain to make sure the Actual begins approaching the

Target.

3. Adjust the Integral Gain

Add some Pressure/Force Integral gain, approximately twice as much as the

Pressure/Force Proportional Gain. The Actual Pressure/Force should go towards the Target

Pressure/Force.

Do not give a lot of Integral Gain, just enough to make sure it eventually gets to the

Target Pressure/Force.

4. Ramp the Pressure/Force Up and Down

For the remainder of the tuning (steps 5, 6 and 7), repeat the following steps for each

gain parameter you change:

1. Ramp the pressure/force with one of the buttons you set up in the Tuning Tools.

2. View the plot.

42

Delta Computer Systems, Inc.