Command: change master (79), Change master (79) – Delta RMC151 User Manual

Page 781

8 Command Reference

the quadrant after a peak and before the midpoint, then the axis will not stop on that

first middle point because it could lead to extreme accelerations. Instead, the axis will

continue a half-cycle after the first middle point and stop at the next middle point.

When the Stop Location is set to Middle, the target generator performs the stop

by ramping the frequency down to zero over the last quarter-cycle. Due to this, any

attempt to ramp the frequency with the Change Target Parameter (80) command

during this portion of the move will be ignored.

•

Pos Peak

The sine move will stop at the next positive peak.

•

Neg Peak

The sine move will stop at the next positive peak.

•

Next Peak

The sine move will stop at the next peak, whether it is negative or positive.

Status Bits

In Position Bit

After the target position stops, and the Actual Position is within the In Position Tolerance

window, the In Position Status bit will be set. This bit indicates that the move is complete

and the axis is at position.

Target Generator Bits

The Target Generator bits in the Status Bits register indicate which portion of the move

the axis is currently in. These bits are useful when programming complex motion

sequences.

Target Generator Done bit

This bit indicates the move is complete, which occurs when the target has stopped.

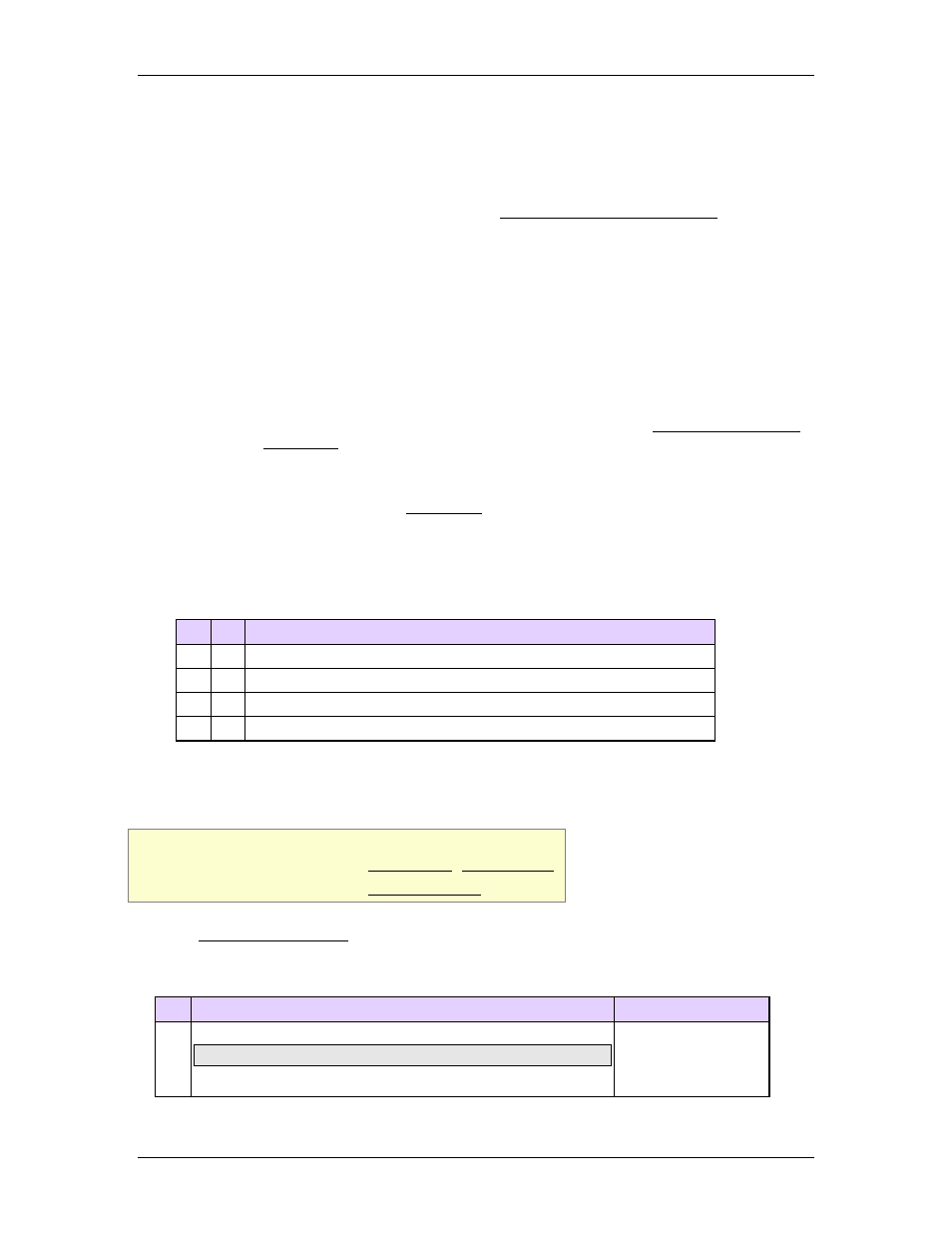

Target Generator State A and B bits

B

A Description

0

0

Reserved

0

1

Reserved

1

0

Reserved

1

1

Reserved

8.4.7.4. Command: Change Master (79)

Supported Axes: Position Control Axes

Supported Control Modes: Position PID, Position I-PD

Firmware Requirement: 3.56.0 or newer

See the Commands Overview topic for basic command information and how to issue

commands from PLCs, HMIs, etc.

Command Parameters

# Parameter Description

Range

1 Master Register

Note: See Specifying a Register Address below.

_Time or any

other valid

register of type

REAL.

deltamotion.com

761