Using profinet record data, E record data, E using profinet record data – Delta RMC151 User Manual

Page 495

6 Communication

Indirect Data Map

The only data guaranteed to be consistent are variables, if they are placed first in the

Incoming Data area of the Indirect Data Map. The size of guaranteed consistent data

depends on the loop time:

•

1 ms or longer loop time: The first 100 registers will be consistent if they are

all variables.

•

500 us loop time: The first 50 registers will be consistent if they are all

variables.

•

250 us loop time: The first 25 registers will be consistent if they are all

variables.

As soon as the first register is encountered that is not a current or initial variable

register, the guarantee for data consistency no longer applies. Remaining registers in

the I/O block will be processed as time allows on subsequent motion loops, taking up

to a maximum of 10 ms. For this reason, variables should be included first in the

Incoming I/O Data Area of the Indirect Data Map in order to ensure their consistency.

Notice that if commands are mapped to the Indirect Data Map, the commands will all

be submitted at the same time, after all values have been written.

Other Locations

No data consistency is guaranteed when consuming in other areas (such as axis

parameters). The entire write can take as long as 10 ms, with the write being deferred

to the next control loop at any point as required to meet loop time requirements.

6.8.10.7.4. Using PROFINET Record Data

PROFINET defines Record Data in addition to the cyclic I/O data exchange. The PLC can read

or write these records using RDREC and WRREC or similar function blocks. Each data record

within a PROFINET device is addressed through the Slot, Subslot, and Index. The RMC

supports three types of data records: fixed, custom, and PROFINET-specific. Only the first two

are typically of interest to RMC users.

PROFINET allows the caller to specify the length of the data being read, but does not specify a

starting offset within the given data record. Therefore, the PLC can only read or write starting

at the beginning of a data record.

Fixed Data Records

The RMC defines one data record for each RMC register file with the index of each match

the number of the register file. Fixed data records are addressed as Slot 0, Subslot 1, and

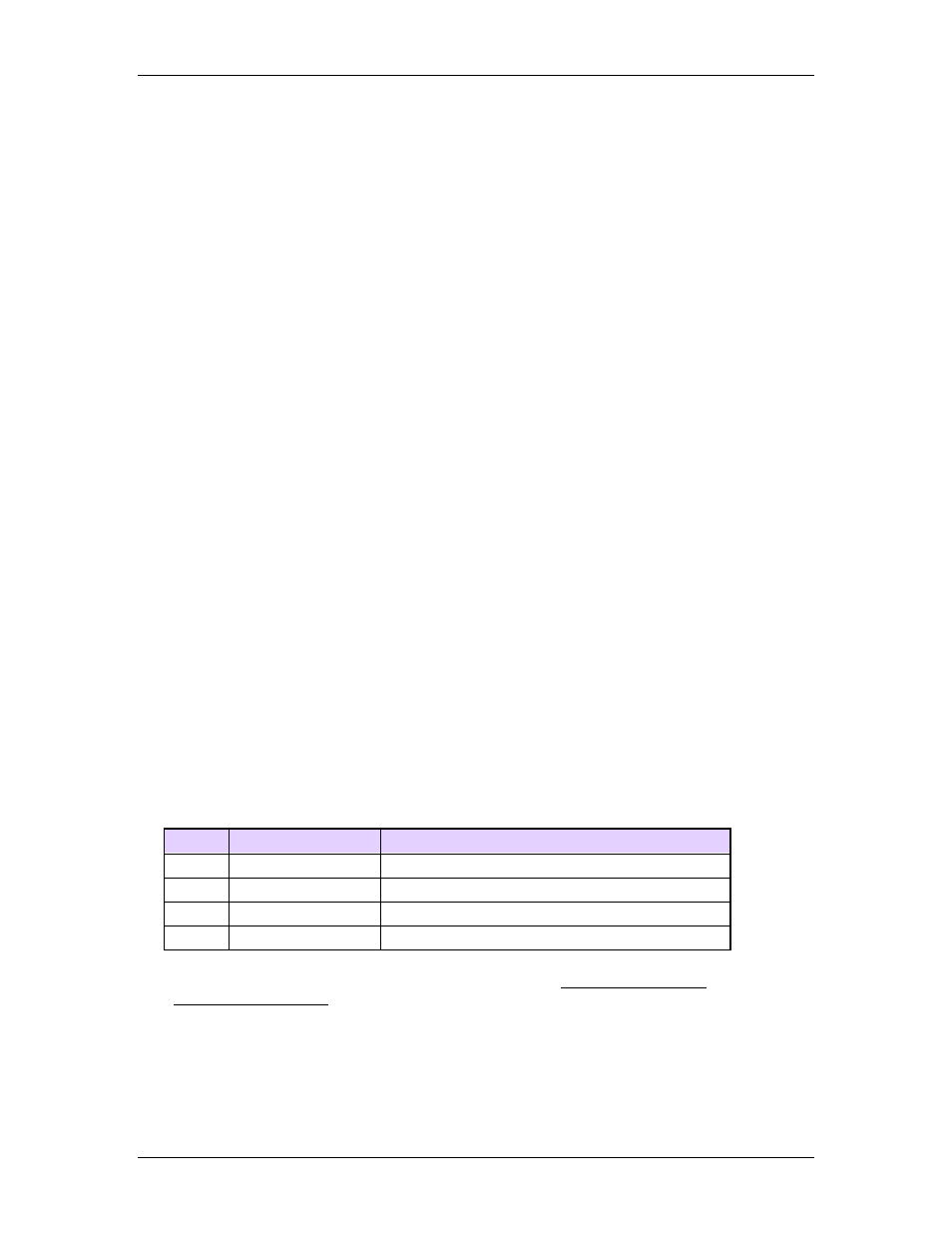

Index of 7-255:

Index

Starting Address

Description

7

%MD7.0

Contents of RMC register file 7

8

%MD8.0

Contents of RMC register file 8

:

:

:

255

%MD255.0

Contents of RMC register file 255

For a list of the register files and their content see the RMC70 Register Map or the

RMC150 Register Map.

Notice that because PROFINET always starts its reads and writes at the beginning of the

data record, fixed data records can only be used to read or write starting at the beginning

of an RMC register file. Custom Data Records get around this limitation.

Custom Data Records

deltamotion.com

475