Switching feedback using custom feedback, Switching feedback on, The fly – Delta RMC151 User Manual

Page 198: Switching feedback

RMC70/150 and RMCTools User Manual

3.10.2. Switching Feedback using Custom Feedback

Switching feedback on the fly can be implemented in the RMC via Custom Feedback. This

topics describes how.

Tip: Theof Delta'sincludes a Switching Feedback example.

You can use that example to help you get started.

Setting Up Switching Feedback

Read the Custom Feedback topic before completing this procedure.

1. Define a Control Axis with Custom Input

a. Define a control axis with the feedback type required (position, velocity, pressure,

force, or acceleration). For the feedback source, choose Custom.

2. Define the Reference Axes

a. Create reference axes for each physical feedback input to be used.

3. Configure the Reference Axes

a. Configure the feedback parameters for the reference axes and verify that the

transducer gives valid readings.

b. Set the Scale and Offset so that the reference axes provide correct values throughout

the entire range of feedback.

4. Create a Variable

Create a variable in the Variable Table to specify which feedback will be used, for example

ActiveFeedback. The type can be either REAL or DINT.

5. Create a User Program

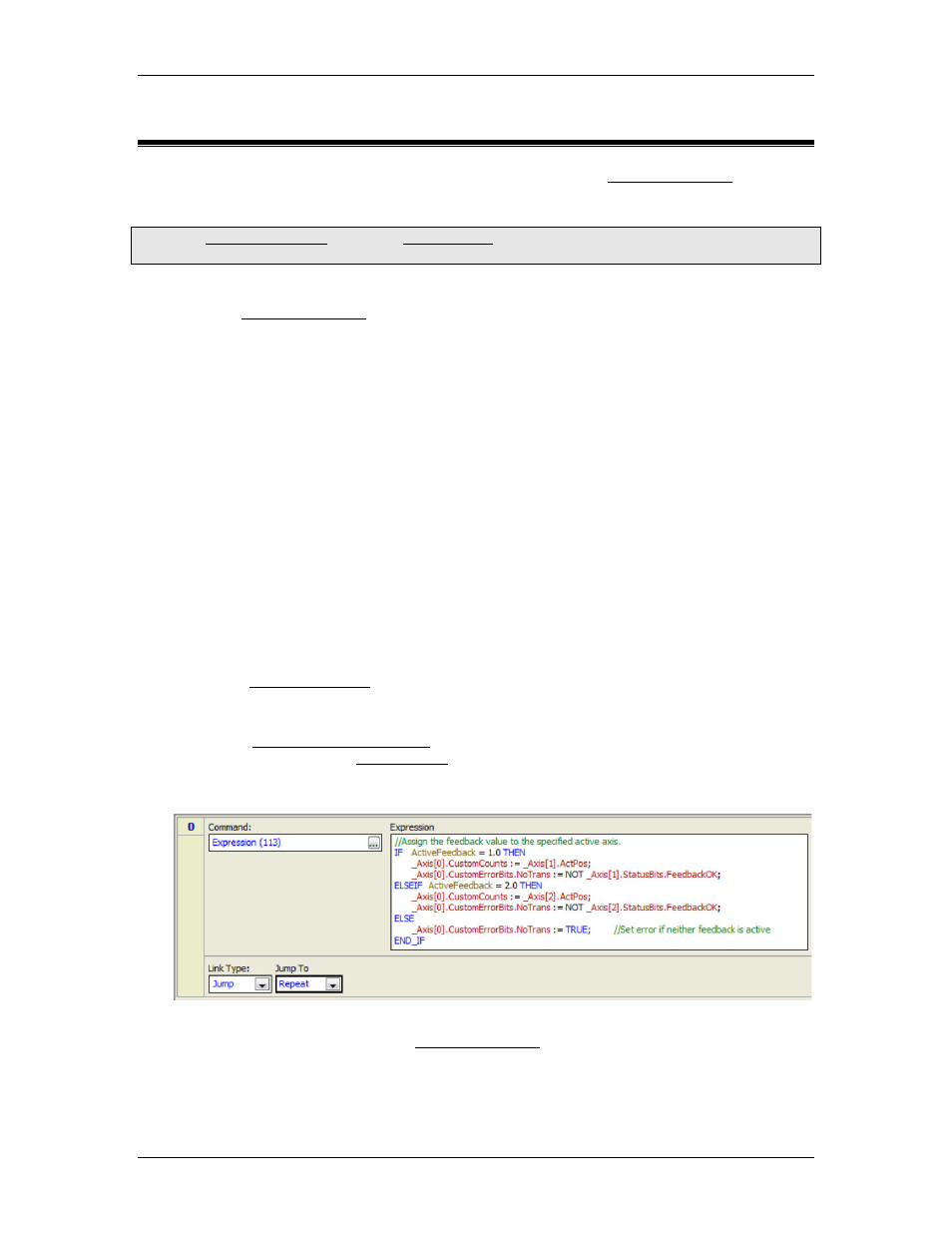

a. Create a single-step user program with a Jump Link Type and a Repeat Jump To

location.

b. Add an Expression (113) command.

c. Create an expression that assigns the feedback value from the reference axes to the

CustomCounts of the control axis, based on the value of the ActiveFeedback variable.

d. Set the CustomErrorBits.NoTrans bit according to the state of the active feedback. This

can be done by using the Feedback OK status bits of the reference axes.

For example:

6. Make Sure the User Program Always Runs

As described in more detail in the Custom Feedback topic, do the following:

a. Set the RMC to start in RUN mode.

b. Use a _FirstScan condition in the Program Triggers to start the user program when the

RMC enters RUN mode.

178

Delta Computer Systems, Inc.