Delta RMC151 User Manual

Page 134

RMC70/150 and RMCTools User Manual

3. Enter Maximum Acceleration

Enter the desired maximum acceleration. This is not necessarily a true limit of the

acceleration, but helps determine the response of the simulator and the tuning gains.

For best results, set this value significantly higher than the acceleration rates you

intend to use on the axis. This value is typically at least an order of magnitude (10x)

greater than the maximum velocity.

4. Enter Pressure or Force Information

If the axis is position-pressure or position-force, enter the maximum force of the

simulator, and the desired range of the force area at the ends of the travel.

The tuning of the pressure or force is affected by the position settings, especially the

Maximum Acceleration. If the pressure or force tuning is poor, or pressure or force

following errors occur, run the Simulator Wizard again and increase the Maximum

Acceleration.

5. Review Parameters

Click Next and review the axis parameter settings in the Proposed column. Any

parameters with blue text can be changed. When you are satisfied with the values,

click Finish.

6. Download Axis Parameters

In the Axis Tools window, click the download button to apply the parameter

changes to the controller.

After setting these parameters, make sure to enable the axis. This can be done by

sending the Enable Controller (7) to the RMC. To do a basic move on the axis, send the

Move Absolute (20) command.

Note: The simulator wizard will set the simulator to 2

nd

order.

Simulating a Real System

The simulator can be configured to approximate your actual system. The simulator

parameters are in the Axis Tools, in the Axis Parameters, on the All tab, in the

Simulator section. You will need to set the parameters listed in the table below. Use the

guidelines below to calculate the Simulate parameters to approximate your real system:

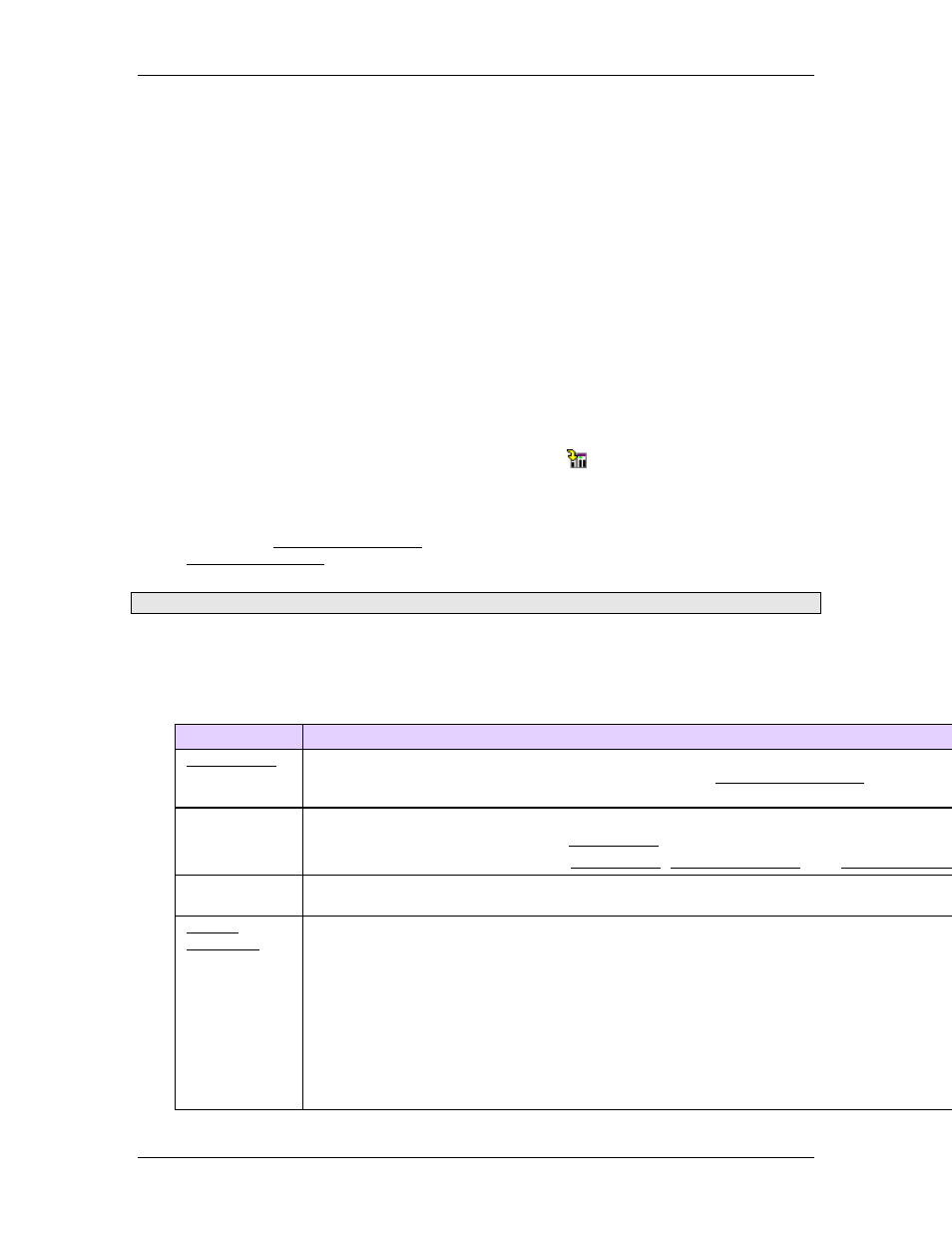

Parameter

To calculate this parameter:

The System Gain units are pu/s/V, which is the speed the system moves for 1 V of control

To find this value, give 1 volt of Control Output (use the Open Loop Rate (10) command).

plot to find the steady-state Actual Velocity of the system. This is your System Gain.

Simulator

Order

The simulator can be set to 1

st

or 2

nd

order.

A 1

st

order system is defined by the System Gain and Time Constant.

A 2

nd

order system is defined by the System Gain, Natural Frequency, and Damping Factor

Time Constant

For a 1

st

order system. To calculate the time constant, determine the time it should take th

velocity to reach 95% of the steady state, and divide by 3.

For a 2

nd

order system. The Natural Frequency for a hydraulic system is normally between

30. Use the following formula to calculate the natural frequency for hydraulic system:

ω

= sqrt[(4*200000 *A

2

) /(mass * volume)]

where

ω =

Natural Frequency (Hz)

A = area of the piston (in

2

)

mass = the mass moved by the system (lb)

114

Delta Computer Systems, Inc.