Delta RMC151 User Manual

Page 115

3 Controller Features

•

Pneumatics

Due to the compressibility of air, pneumatic systems are notorious for oscillating. The

active damping limits the oscillation, resulting in much better control.

•

Small Hydraulic Cylinders with Large Loads

In hydraulic cylinders with a large mass and a relatively small bore, the effects of the

compressibility of the oil are the most pronounced, and can result in oscillation. Active

damping limits the oscillation, resulting in much better control. In certain cases, the

use of active damping can decrease the bore of the cylinder required, which can also

reduce the size of the hydraulic power unit.

Deciding whether a System Needs Active Damping

To determine whether a system needs active damping, give it an open loop Control

Output. If the system oscillates, especially after the initial start of motion, it could benefit

from active damping.

Active Damping Options

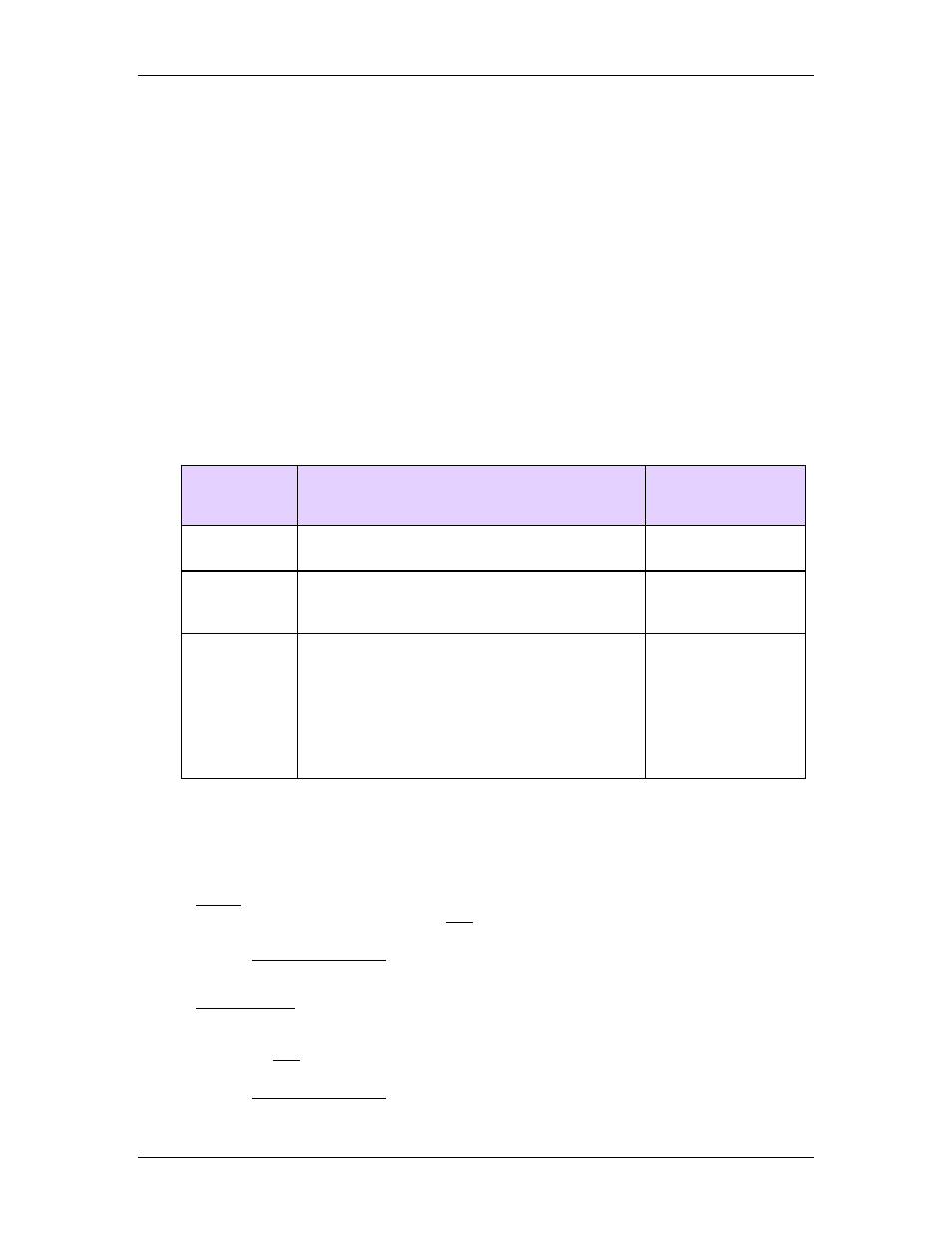

Active damping requires information on the accelerations or forces acting on the system.

This information can be obtained in a variety of ways. The table below lists the options

available. Typically, using accelerometers or force feedback provides the best control.

Position-based acceleration does not provide as good control.

Active

Damping

Type

Possible Sources

Required Axis Type

Force

Secondary Force Input (single- or dual-input)

Position-Force* or

Velocity-Force*

Acceleration

Input

Secondary Acceleration Input (single- or dual-

input)

Position-Acceleration

or

Velocity-Acceleration

Position-based

or or Velocity-

based

Acceleration

Position or Velocity Input (uses the Actual

Acceleration of the feedback)

•

Unfiltered Acceleration (not

recommended)

•

Filtered Acceleration (not

recommended)

•

Modeled Acceleration

Position or Velocity

*In rare cases, Active Damping with pressure feedback is possible on a position-pressure

or velocity-pressure axis, requiring a secondary pressure input, but is generally not

recommended.

Setting Up Active Damping

Pressure or Force Input

a. Define a position-pressure or position-force axis. On the RMC70, this secondary

pressure or force input requires an AP2 module. On the RMC150, the CPU must have

the pressure control option, designated as RMC151.

b. Set the High-Order Control parameter to Active Damping.

Acceleration Input

a. Define an axis with a secondary acceleration input. If you are using one

accelerometer, choose Accel (single-input). If you are using two accelerometers,

choose Accel (dual-input, diff.). On the RMC70, the secondary acceleration input(s)

require an AP2 module. On the RMC150, the CPU must have the pressure control

option, designated as RMC151.

b. Set the High-Order Control parameter to Active Damping.

deltamotion.com

95