Delta RMC151 User Manual

Page 752

RMC70/150 and RMCTools User Manual

5 Jerk Rate (position-units/s

3

)

Any REAL number

Description

This command electronically gears the axis to the requested register, using this register

as the master position. Typically, the master register is the Target or Actual Position of

another axis. The slave ramps its target velocity using the Acceleration Rate and Jerk

Rate (rate of change of acceleration) parameters until it reaches the synchronized gear

ratio. The gear ratio is determined by the Numerator and Denominator.

This command is more robust than Gear Pos (Clutch by Time) (30) in that it avoids slave

velocity discontinuities if the initial master velocity is low.

See the Gearing Overview topic for general information about gearing, including Gear

Ratio, Clutching and possible Gear Masters.

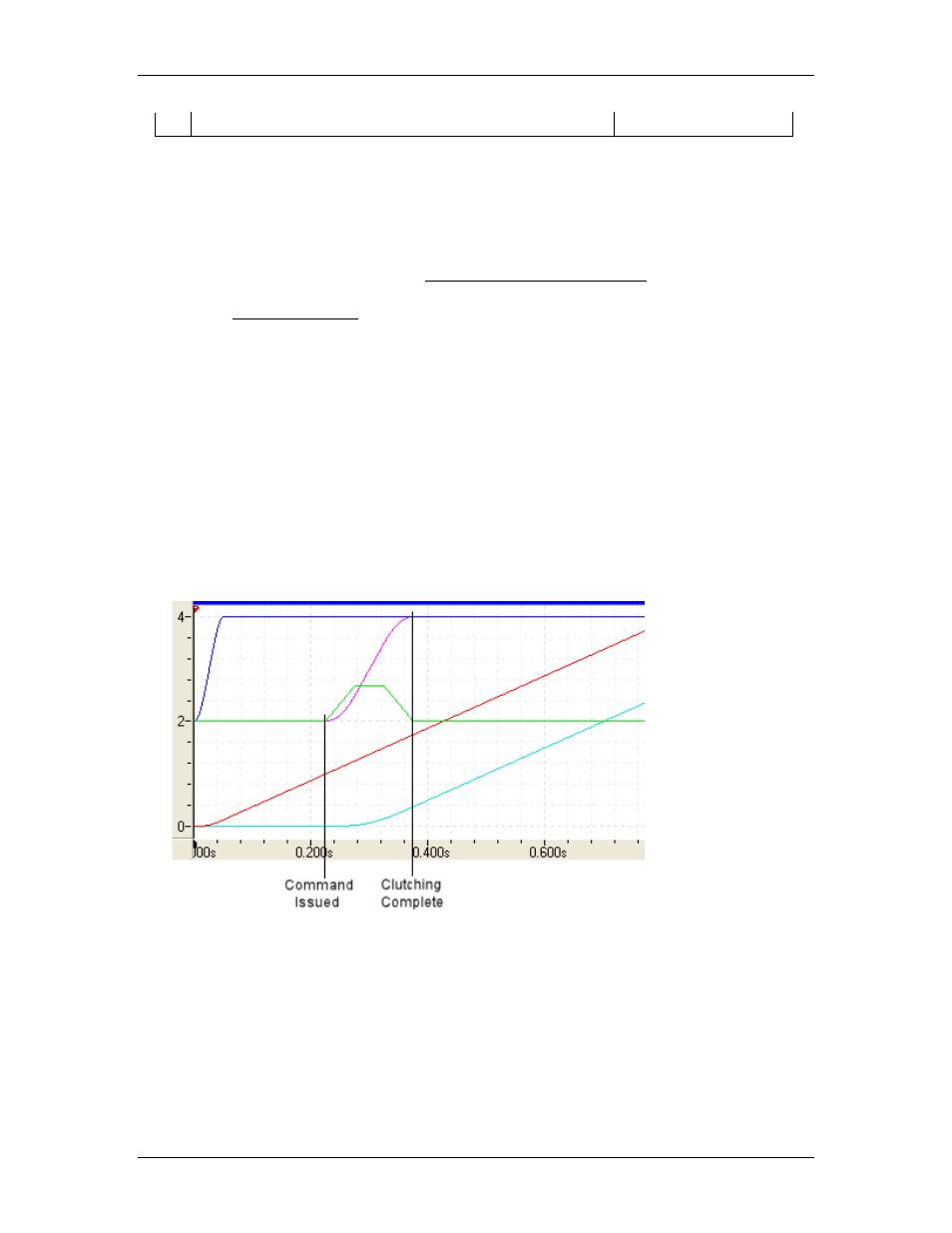

Gear Position (Clutch by Rate) Example

In this example, Axis 1 (slave) gears to Axis 0 (master) at a 1:1 ratio. The master starts

moving at time 0. When the master reaches 1 pu, the following Gear Pos (Clutch by

Time) command is issued to the slave.

Numerator = 1

Denominator = 1

Master Register = _Axis[0].TarPos

Accel Rate = 50

Jerk Rate = 1000

The plot below shows how the slave moves.

Legend:

— Master Position

— Master Velocity

— Slave Acceleration

—

Slave Position

— Slave Velocity

When the command was issued to the slave, it began ramping up the velocity at the

specified Acceleration and Jerk. As the slave approaches the master, the velocity is

ramped down. The clutching is complete when the slave reaches the specified gear ratio.

Applications Not Suitable for Clutch by Rate:

The Gear Position (Clutch by Rate) command clutches based on a rate, which means it

ramps its target velocity using the acceleration and jerk parameters until it reaches the

synchronized gear ratio. This differs from clutching by distance, in which the axis would

reach the requested gear ratio in a certain distance of travel.

Clutching by rate is not the best method of gearing for applications that require axes to

be geared at a specified ratio by a certain distance, such as flying cut-offs, etc. Use the

732

Delta Computer Systems, Inc.