Delta RMC151 User Manual

Page 509

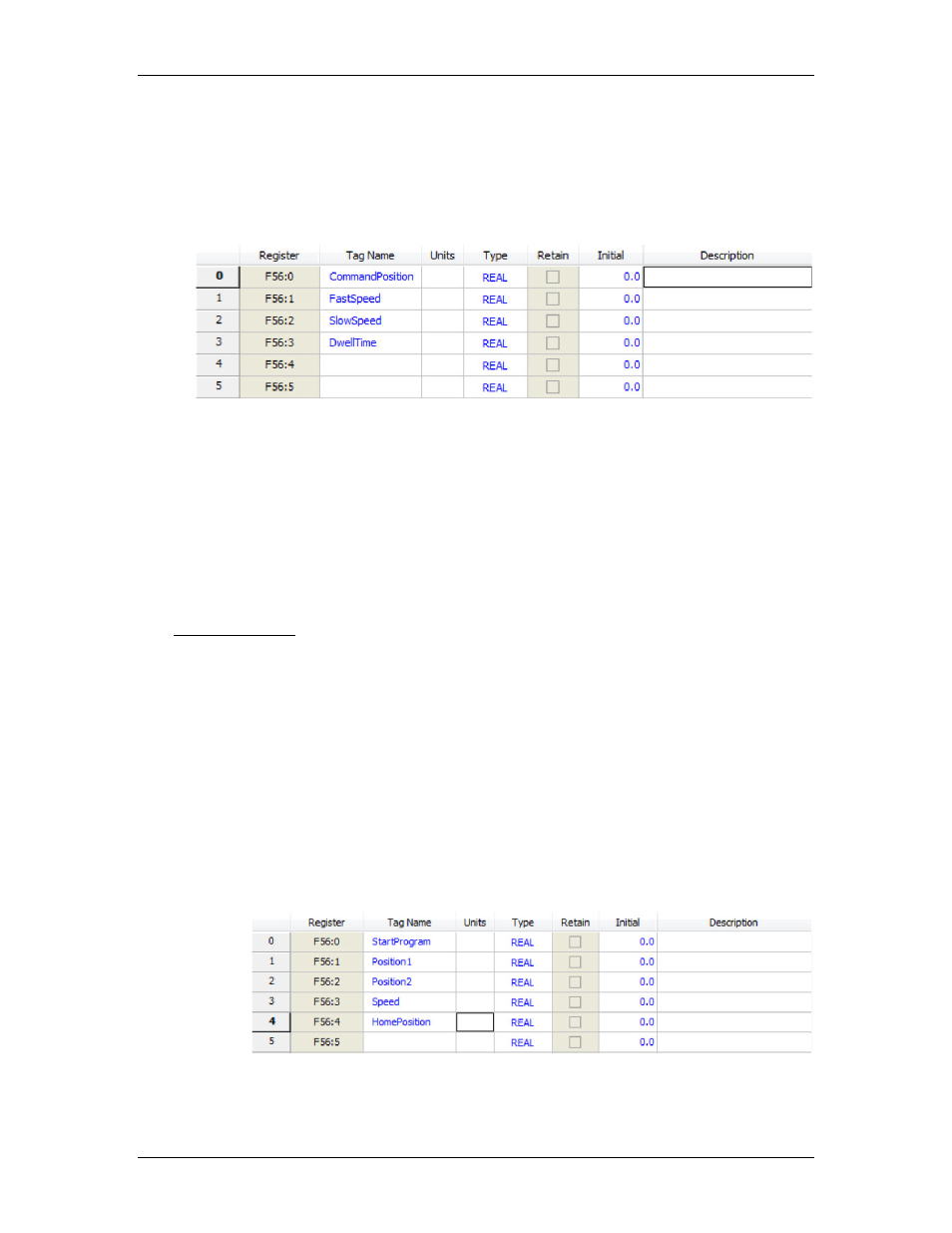

6 Communication

•

Command Position (REAL Data Type)

•

FastSpeed (REAL Data Type)

•

SlowSpeed (REAL Data Type)

•

DwellTime (REAL Data Type)

Therefore, the user sets the tag names and Data Types of the first four items in the

Variable Table like this:

4. Perform Communications

After configuring the PROFIBUS and setting up the Indirect Data Map and Variable Table,

start the PROFIBUS communications. Once the PROFIBUS connection is established, the

RMC's Indirect Data Map registers will continuously be sent to the PLC's Input Data, and

the PLCs' Output Data will continuously be sent to the RMC's Variable Table. The RMC's

variables can be used for anything that they normally are used for. However, trying to

change the PROFIBUS variables from user programs is not very useful, because the

variables will be overwritten by the PROFIBUS.

Issuing Commands via I/O Mode

To issue commands, or write to RMC registers (other than the I/O Mode variables), or do

anything else via the I/O modes, you must create a user program. You can then use the

Program Triggers to start a user program when an I/O Mode variable becomes a certain

value.

To program the RMC to do this, you must:

1. Create user programs to do the desired actions.

2. Define a variable for starting the programs.

3. Edit the Program Triggers to start the user programs based on the value of the

variable.

Example

Bruce is using I/O Mode (8 regs). He wants to run two different user programs on the

machine. The first program will move back and forth once, and the second will move

to a home position. The PLC will send the two cycle positions, the speed, and the

home position to the RMC.

1. Bruce defines variable zero as StartProgram, and defines 4 more variables

for his cycle positions, speed, and home position.

2. Bruce creates the user programs and calls them Cycle and MoveHome:

deltamotion.com

489