Using i/o modes, Profibus mode: i/o modes, Profibus i/o mode – Delta RMC151 User Manual

Page 507: I/o mode (4 registers), I/o mode (8 registers), I/o mode (16 registers), I/o mode (32 registers), E profibus mode: i/o modes, I/o mode, Using i/o modes 6.9.4.1. profibus mode: i/o modes

6 Communication

PROFIBUS network, but the values are not what you expect or do not make

sense, return to this step and try swapping the word order.

•

Click OK.

7. Add any other RMC devices you want on the same network. To do this, repeat steps 5 and

6.

8. Save your configuration.

9. Send the configuration to the master device. This step varies depending on the master

you selected.

6.9.4. Using I/O Modes

6.9.4.1. PROFIBUS Mode: I/O Modes

The RMC's PROFIBUS I/O modes continuously pass blocks of data between the PLC and RMC.

The following modes are available on the RMC150E and RMC75P:

•

I/O Mode (4 registers)

•

I/O Mode (8 registers)

•

I/O Mode (16 registers)

•

I/O Mode (32 registers)

Each of these modes specifies a number of 32-bit registers, n. For each mode, n registers are

continuously sent from the RMC's first n Indirect Data Map registers, and n registers are

always sent from the PLC to the first n registers in the RMC's Variable Tables.

For your application, choose the mode with the number of registers you need. The PROFIBUS

I/O modes are very simple and easy to use. No handshaking is required, and you are free to

use the data as you wish. The PROFIBUS data is updated each Loop Time of the RMC.

Put in other words, the PLC's PROFIBUS Input Data comes from the RMC's Indirect Data Map,

and the PLC's PROFIBUS Output Data goes to the RMC's Variable Tables.

The RMC's Indirect Data Map is an area in which any register in the RMC can be mapped to.

Therefore, to have the PLC read any register in the RMC via one of the I/O modes, just put it

in the Indirect Data Map.

The RMC's Variable Table contains variable registers that can be used for any purpose. Writing

to these variables via the I/O modes can do such things as changing settings or profiles, or

starting user programs.

The I/O data is consistent. A block of PROFIBUS data is called 'consistent' if it is consistent

over the length of the block, rather than just over a single 8- or 16-bit data item. Consistent

blocks of data will stay together through the communication, from the time it was captured in

one device until it is delivered to the other device, whereas data from different consistent

blocks could have been sampled at different times.

The I/O modes require firmware version 3.10 or newer.

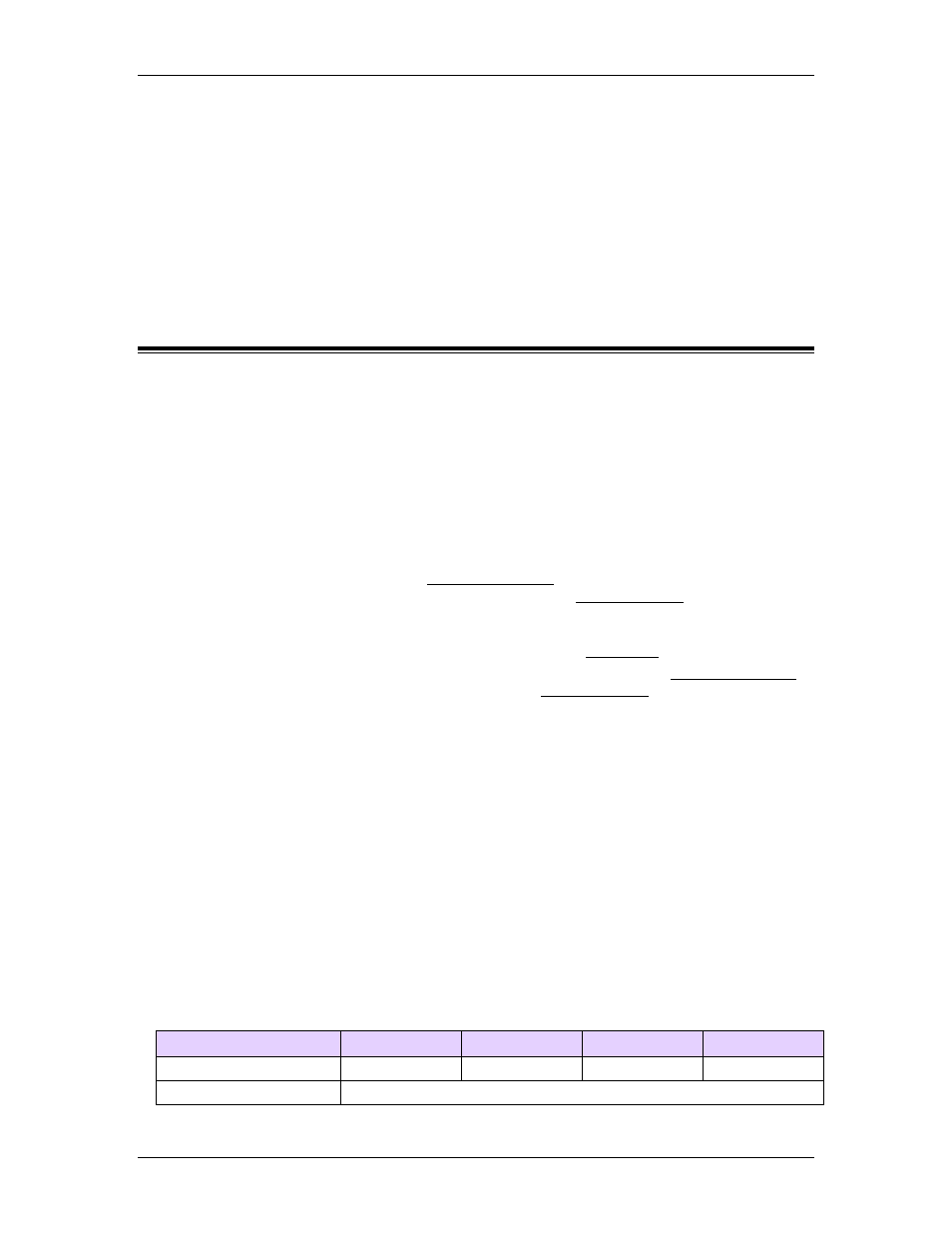

Parameterization

The I/O modes require the PROFIBUS configuration and parameterization listed below.

The GSD file directs the PROFIBUS master setup software to automatically set up these

values, but Delta has found several cases where it is not supported correctly or manual

setup is otherwise required.

I/O Mode:

32 registers

16 registers

8 registers

4 registers

Configuration

C0 FF FF

C0 DF DF

FF

F7

Parameters (bytes

See the PROFIBUS DP specification for details.

deltamotion.com

487