Using omron controllers via ethernet/ip i/o, Omron plcs via ethernet/ip i/o, Using omron – Delta RMC151 User Manual

Page 593: Controllers via ethernet/ip i/o

6 Communication

Some notes about setting up the control word for the SEND and RECV instructions for the

RMC75E are given below:

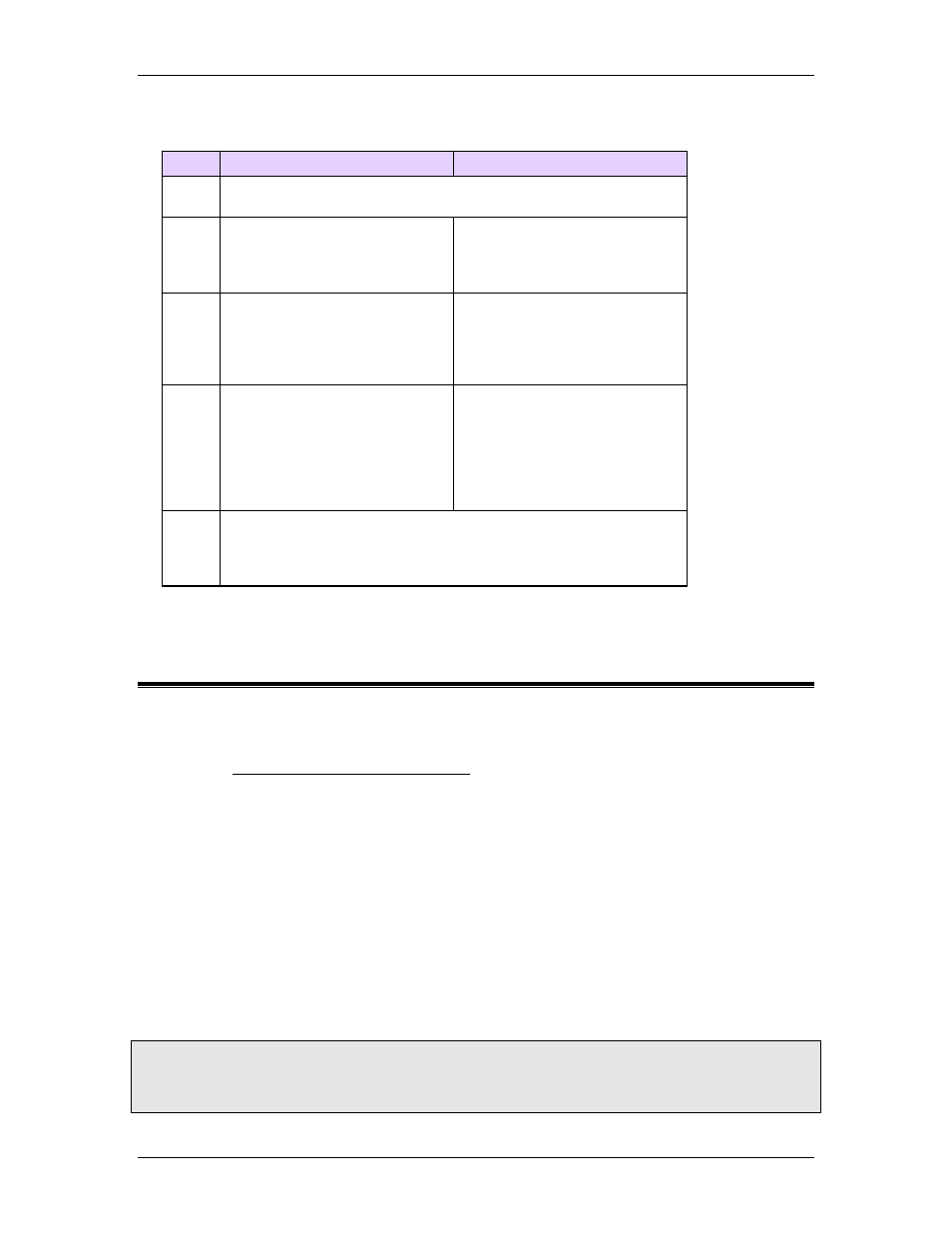

Word Bits 08 to 15

Bits 00 to 07

C

Number of words to read (1 to 512). The PLC supports reads

up to 990 words, but the RMC is limited to 512 words.

C + 1 Always 00 for RMCs.

Remote Network Address.

For RMCs, this value should be

set to the address of the RMC's

Ethernet network.

C + 2 Remote Node Number. For

RMCs, this value should be set

to whichever Node Number will

be mapped to the RMC's IP

address

Remote Unit Number. For

RMCs, this value should be 0.

C + 3 Port Number: 00 to 07. The

Port Number is used to allow

simultaneous communications

in the PLC. Use a different

number for each

communication that may be

requested simultaneously.

No. of Retries: 00 to 0F (0 to

15). For RMC communications,

this value should be between 2

and 5.

C + 4 Timeout: 0001 to FFFF (0.1 to 6553.5 seconds).The default

setting of 0000 sets a monitoring time of 2 seconds. For RMC

communications, this value should be set to 0001 or 0002 for

0.1 or 0.2 second timeouts.

6.11.10. Using Omron Controllers via EtherNet/IP I/O

Several Omron controllers support EtherNet/IP I/O communication. This topic describes how to

configure and use the Omron CS1 and CJ2 PLCs to communicate with the RMC via EtherNet/IP

I/O. For instructions on using the FINS protocol to communicate with an RMC from an Omron

PLC, see the Using Omron Controllers via FINS topic.

Determine I/O Data Locations in the RMC

EtherNet/IP I/O transfers data back and forth between the RMC and PLC at the Requested

Packet Interval (RPI). The user must specify which data items in the RMC should be sent

and received. Typically, this is data in the Indirect Data Map.

Set up the Indirect Data map so that one part contains all the data coming from the PLC

(Incoming Data), and another part contains all the data going to the PLC (Outgoing

Data). Make sure the Incoming and Outgoing Data areas in the Indirect Data Map do not

overlap.

The Outgoing Data typically includes RMC status items that the PLC always needs to keep

track of, such as actual positions and status bits.

The Incoming Data consists of items that the PLC needs to write to in the RMC. This is

typically variables and possibly command registers.

Note:

The Incoming and Outgoing Data locations need not be the Indirect Data Map. However, the

Indirect Data Map is usually the best choice. Other options are the Variable Table and the

command area.

deltamotion.com

573