Delta RMC151 User Manual

Page 617

6 Communication

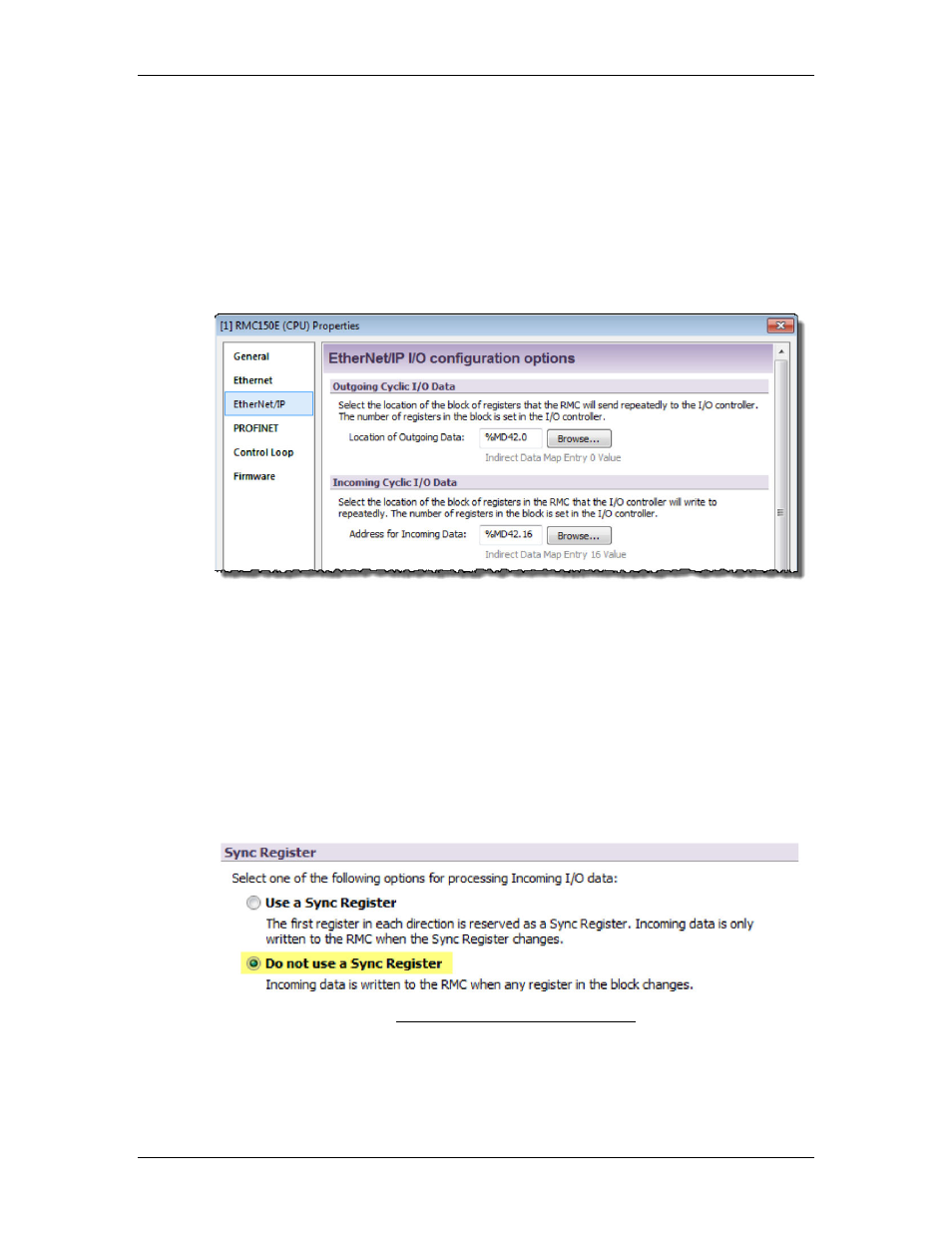

In the Outgoing Cyclic I/O Data section, enter the starting location for the

Outgoing Cyclic I/O Data. In our example, verify that the location is the Indirect

Data Map Entry 0 Value.

In the Incoming Cyclic I/O Data section, enter the starting address for the

Incoming Cyclic I/O Data. Click the Browse button and browse to the desired RMC

location for the outgoing data. This should be a location in the Indirect Data Map,

the Variable Table, or Command Area as discussed in the Determine I/O Data

Locations in the RMC section above.

For example, the PROFINET Settings Page below shows an RMC150 with the

Outgoing Data coming from the Indirect Data map starting at item 0 and the

Incoming Data going to the Indirect Data starting at item 16.

5. Choose Whether to Use a Sync Register

The Sync Register provides a method for the PLC to synchronize the Input Data and

Output Data. With a Sync Register, the Incoming Data is not written to the RMC

until the Sync Register changes. If you prefer to have the Incoming Data be written

whenever any value in the Incoming Data changes, choose the option to not use a

Sync Register.

Because the S7 PLCs use the DPRD_DAT (SFC14) and DPWR_DAT (SFC15) system

functions to control when the data is copied into and out of the S7’s DBs, the Sync

Register generally does not need to be used with the S7.

To select whether or not to use the Sync Register, in the Project pane, expand the

Modules folder, double-click the CPU module, and choose PROFINET. Then select

the desired option under Sync Register:

For more details, see the Using a PROFINET I/O Connection topic.

6. Configure Custom Data Records

While Custom Data Records can be set up at this time, they are not required to

establish the PROFINET connection, and are generally better to set up later in the

deltamotion.com

597