Command: track position (57), Track position (57), Track position – Delta RMC151 User Manual

Page 769

8 Command Reference

Timing Considerations

When looping through long arrays with the Advanced Gear Move command, precise

timing is often important. Each task can execute a maximum of one step per loop time.

However, the commands in a step and the link condition in that same step are not

executed in the same loop time.

When a step is executed, the commands in that step are issued in that loop time. Then, in

the next loop time of the controller, the Link Type is evaluated. When the Link Type

condition becomes true or tells the program to jump, the program will jump to the

specified step and issue the commands in that step in the same loop time that the

condition became true.

If the master position moves beyond one of the endpoints and the gear ratio rate at that

endpoint is non-zero, the polynomial will continue for two loop times, and if a new

command is not issued during this time, then a Closed Loop Halt will occur and the

Runtime Error bit will be set. Make sure to create your program such that the next

Advanced Gear Move command will be issued within two loop times after reaching one of

the endpoints. The Target Generator Status bits can be used to check whether the master

has moved beyond an endpoint. See the Target Generator State Bits section below.

Target Generator State Bits

The Target Generator bits in the Status Bits register indicate which portion of the move

the axis is currently in. These bits are useful when programming complex motion

sequences.

Target Generator Done bit

Set when the master is at or beyond the Master Sync Position.

If the master is at or beyond the Master Sync Position, and the final Gear Ratio Rate is

zero (0), this bit will be latched and the gear ratio will no longer change even if the

master moves back within the Profile Range.

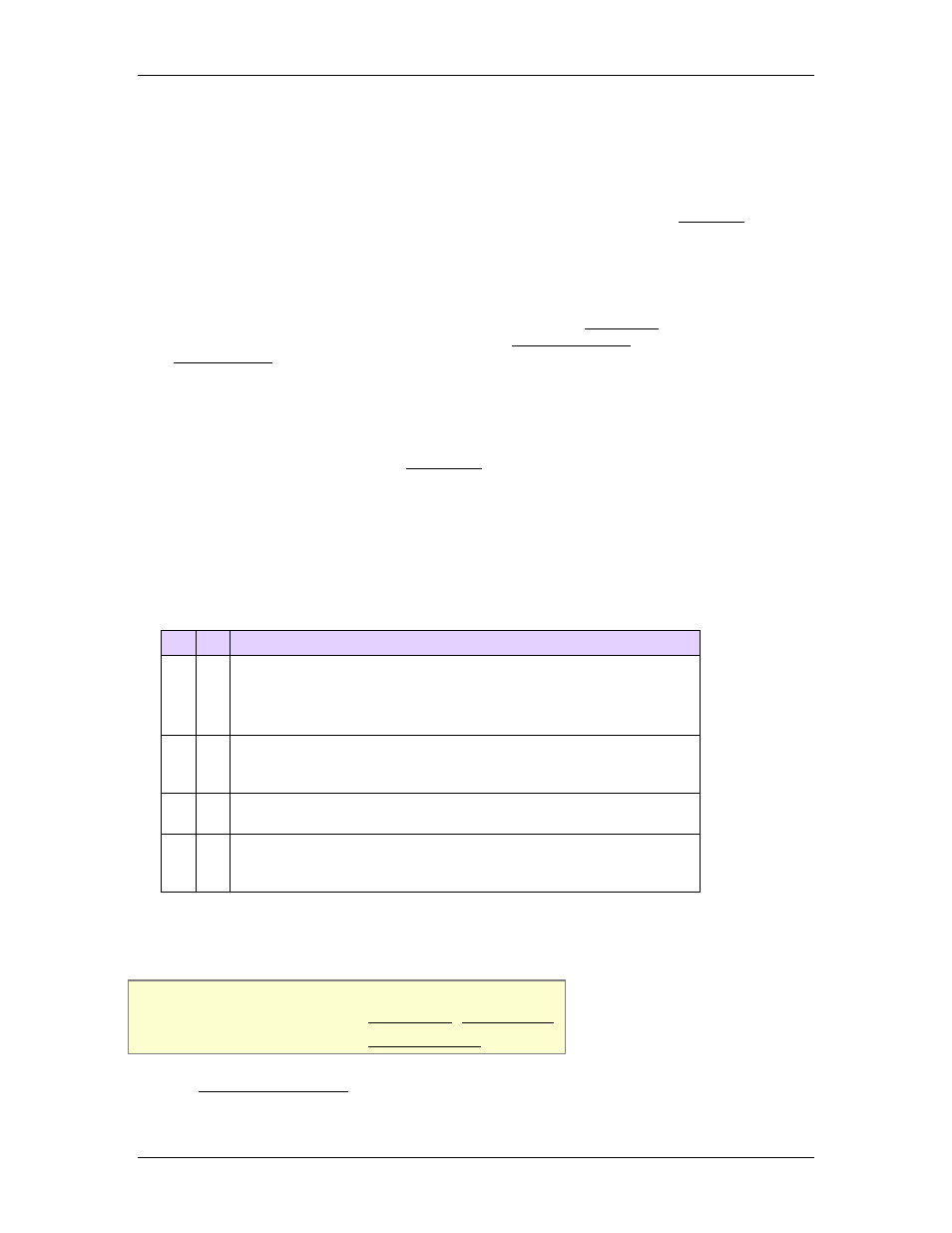

Target Generator State A and B bits

B

A Description

0

0

The master is within the Profile Range.

Or, the master has moved beyond the Master Sync Position

and the final Gear Ratio Rate is zero. Use the Target Generator

Done bit to determine which is the case.

0

1

The master is beyond (not at) the Master Sync Position and

the final Gear Ratio Rate is non-zero. The axis will fault if a

new command is not received in the next control loop.

1

0

The master is prior to the Master Start Position, and the initial

gear ratio rate is zero.

1

1

The master is prior to (not at) the Master Start Position and the

initial gear ratio rate is non-zero. The axis will fault if a new

command is not received in the next control loop.

8.4.6.9. Command: Track Position (57)

Supported Axes: Position Control Axes

Supported Control Modes: Position PID, Position I-PD

Firmware Requirement: 3.58.0 or newer

See the Commands Overview topic for basic command information and how to issue

commands from PLCs, HMIs, etc.

deltamotion.com

749