Delta RMC151 User Manual

Page 207

3 Controller Features

Magnetostrictive Displacement Transducers (MDT) are absolute position transducers designed

for use in rugged industrial environments. They are non-contact, wear-free, highly reliable,

and offer accurate and repeatable linear position measurement. In the motion control

industry, magnetostrictive displacement transducers are typically inserted into hydraulic

cylinders for measurement of the cylinders position.

For MDT Start/Stop or PWM feedback with a typical calibration value of 9 µs/in, the maximum

resolution supported by the RMC70 is 0.0005 in with 1 recirculation. The maximum resolution

supported by the RMC150 is 0.001 in with 1 recirculation.

MDT feedback is supported by the following modules:

RMC70: MA axis module

Each axis on the RMC70 MA axis module can be individually configured for MDT or SSI

inputs.

RMC150: MDT module

Each RMC70 or RMC150 MDT axis can be configured for a Start/Stop transducer or a Pulse

Width Modulated transducer.

Start/Stop

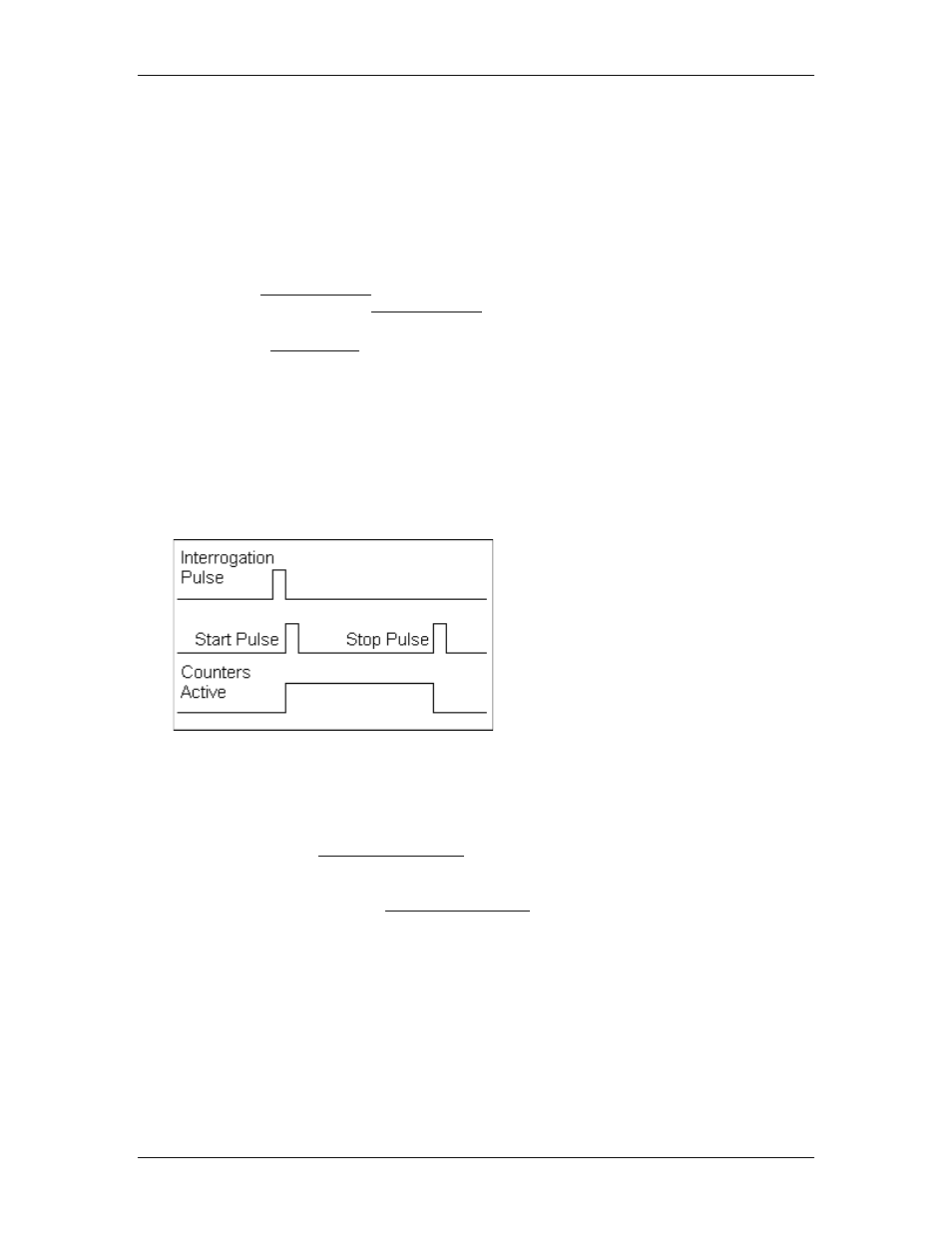

To make a measurement with a Start/Stop transducer, the RMC sends an interrogation

pulse to the transducer. The transducer responds by returning 2 pulses—a Start pulse

and a Stop pulse. The RMCs internal counters begin to count when the first pulse, Start,

is received and stop counting when the second pulse, Stop, is received. The time between

the start pulse and the stop pulse is proportional to the transducer position.

Start/Stop Pulse Transducer

Blanking Period (For Neuter Outputs)

After the RMC receives the start pulse, it waits a brief amount of time before looking for

the stop pulse. This time, called the MDT blanking period, gives time for noise to settle

out.

The RMC150 has an MDT Blanking Period parameter, with options of 5µsec or 21µsec.

The default value is 5µsec. Some older transducers, such as Temposonics I and II with

neuter outputs, require the longer blanking period of 21µsec, due to noisy signals.

The RMC70 does not have an MDT Blanking Period parameter and always uses a 5µsec

blanking period. Therefore, Temposonics I and II transducers with neuter outputs should

not be used with the RMC70, but can be used with the RMC150.

PWM

To make a measurement with a Pulse Width Modulated transducer, the RMC sends an

interrogation pulse to the transducer. The transducer responds with a return signal. The

return signal is high while the transducer is determining its position. The RMC counts

during the time that the return signal is high. The time that the return signal is high is

proportional to the transducer position.

deltamotion.com

187