Wiring guidelines, Wiring and installation 7, Wiring guidelines 7 – Delta RMC151 User Manual

Page 1147: E wiring, Wiring and installation

10. Wiring and Installation

10.1. Wiring Guidelines

Proper wiring of the RMC and of the system is important for proper machine control. Poor

wiring is a common source of noisy feedback, drive signals or digital I/O. Follow the guidelines

in this topic and the other wiring topics to ensure a low-noise system.

General Wiring Instructions

For CE compliance and to minimize electrical interference:

•

Use twisted pairs for all wiring where possible.

•

Use shielded cables for all wiring.

•

Keep RMC wiring separate from AC mains or conductors carrying high currents,

especially high frequency switching power such as conductors between servo drives

and motors or amplifiers and proportional valves.

For UL and CUL compliance:

•

Power supply must be Class 2.

•

All RMC inputs and outputs must be connected to Class 2 circuits only.

Fusing

No fusing is required if a Class 2 power supply is used, as required by UL. Class 2 power

supplies are limited to 100W output. This provides sufficient protection for the RMC and

no additional fusing is required.

For Class I, Division 2 compliance (only available for RMC150E with the Class I,

Division 2 designation)

•

The RMC150E USB port is intended for configuration, programming, and

troubleshooting purposes only. Do not leave it connected during normal machine

operation, as it is sensitive to electrical noise.

•

Conductors must be copper only.

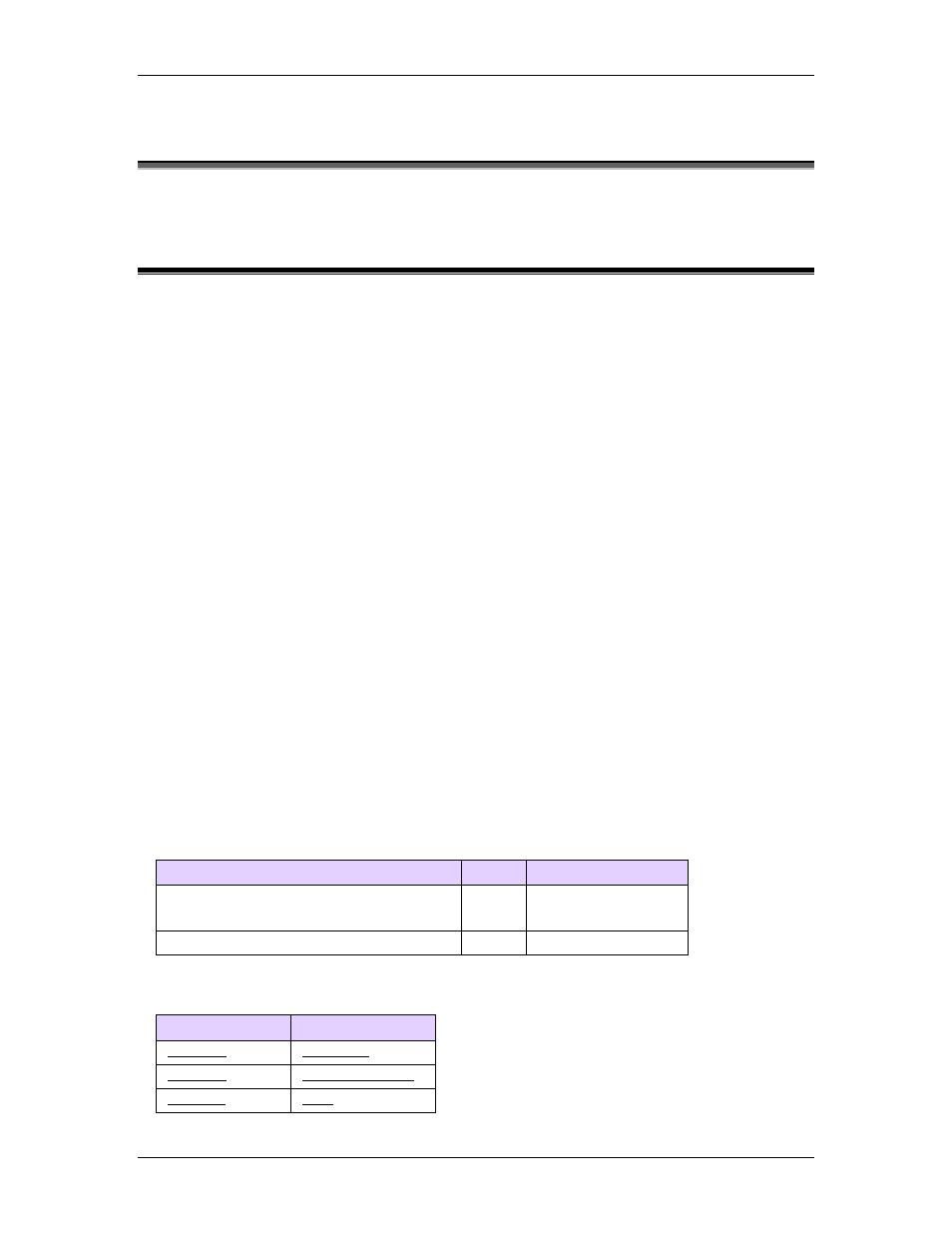

Terminal Block Wires and Clamp Screw Torque

Tighten the wire clamp screws on the terminal blocks to:

Module

AWG

Torque

RMC150E, MDT (M), SSI (S), ANLG (H),

ANLG INPUTS (A), ANLG2 (G), RES (R)

26-12 4.5 lb-in (0.51 Nm)

DI/O, UI/O

28-16 2.2 lb-in (0.25 Nm)

Specific Wiring Instructions

Each RMC module has specific wiring diagrams. Follow the links below for wiring details:

RMC70 Wiring RMC150 Wiring

RMC75E

deltamotion.com

1127