Synchronized, Command: sync move absolute (13), Sync move absolute (13) – Delta RMC151 User Manual

Page 726

RMC70/150 and RMCTools User Manual

•

The Requested Distance must be set such that the move direction in position

units matches the sign of the Control Output. That is, if the Requested Output is

positive, the Requested Distance must be set such that the axis will move in the

position direction.

See the Open Loop Absolute (11) topic for more details.

8.4.4. Synchronized

8.4.4.1. Command: Sync Move Absolute (13)

Supported Axes: Position Control Axes

Supported Control Modes: Position PID, Position I-PD

Firmware Requirement: 3.00 or newer

See the Commands Overview topic for basic command information and how to issue

commands from PLCs, HMIs, etc.

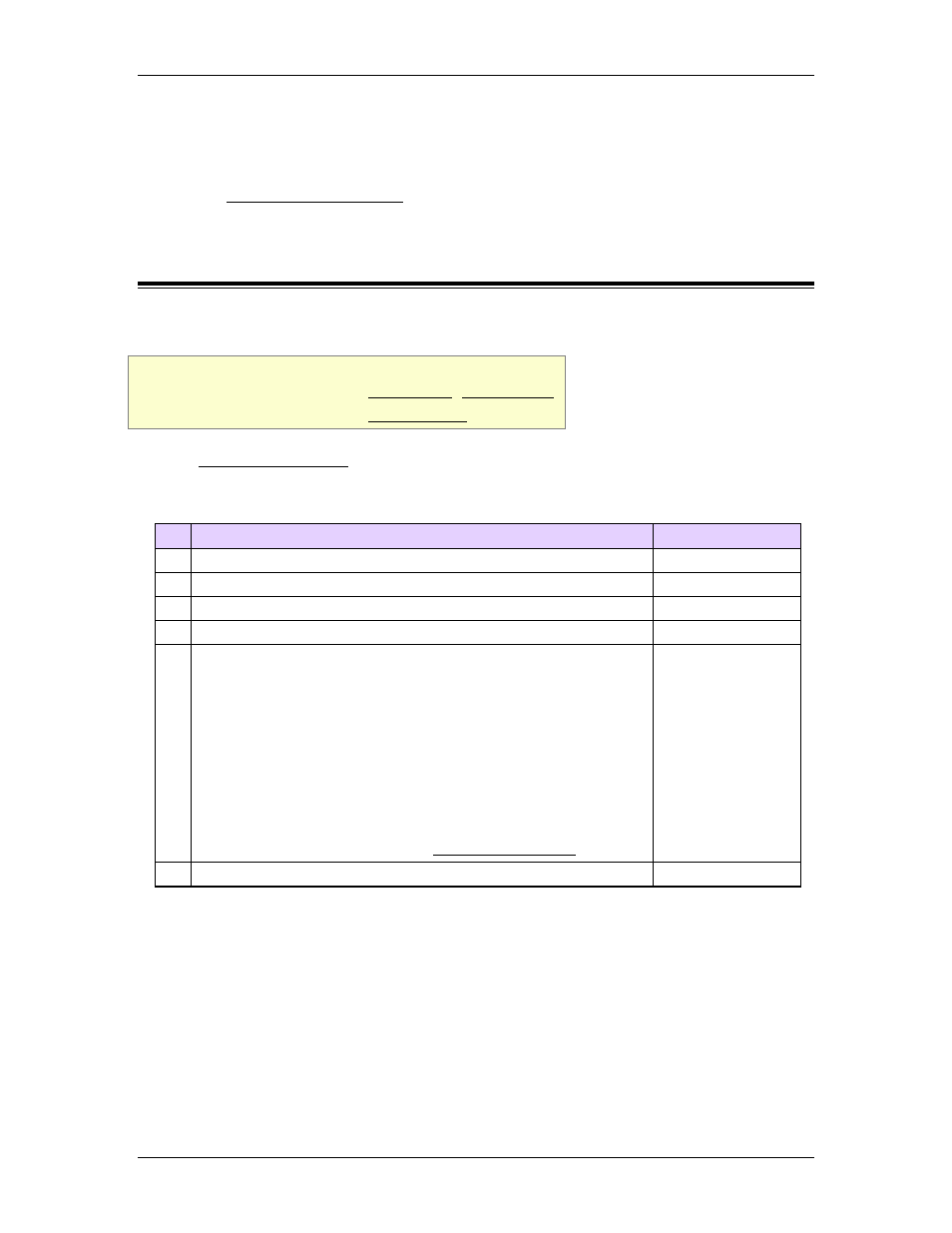

Command Parameters

# Parameter Description

Range

1 Requested Position (position-units)

any

2 Requested Speed (position-units/s)

>0

3 Acceleration Rate (position-units/s

2

)

>0

4 Deceleration Rate (position-units/s

2

)

>0

5 Direction

•

Negative* (-1)

•

Nearest (0)

•

Positive* (1)

•

Current* (2)

•

Absolute* (3)

* These options are intended for use with rotary axes.

However, all options are available on linear axes, but have no

effect. For more details, see the Using Rotary Motion topic.

a valid integer as

described

6 Sync Group

0 to 10

Description

This command initiates a ratioed synchronized move on the axis. In this type of

synchronization, the motion of all the axes in the same Sync Group are synchronized

such that all the axes start and stop moving simultaneously, and at any point during the

move, each axis has completed the same percentage distance (or ratio) of its move. For

example, if three axes start at 0 inches, and are to move to 2, 4, and 6 inches,

respectively, then at any point in the move, these axes' positions will be at a 1:2:3 ratio.

Synchronized moves are useful when several actuators are moving a rigid structure

around a fulcrum. The axes do not need to start or stop at the same positions.

How to Start a Sync Move

706

Delta Computer Systems, Inc.