Gearing, E gearing – Delta RMC151 User Manual

Page 129

3 Controller Features

3.6.4. Gearing

Gearing is used when one axis (the slave axis) must move incrementally and proportionately

to a register (the gear master), which is typically the position or velocity of another axis. The

RMC has several commands to cover a wide range of simple and advanced gearing

applications. This topic describes the basics of gearing and gives an overview of the gearing

commands.

If you need to gear using a non-linear profile, see the Curves Overview topic.

In general, to gear an axis, issue a gearing command to the axis to be geared (the slave axis).

The axis will remain geared until another command is issued to the axis. A register does not

need to do anything to become the master of a gearing relationship. The slave axis will select

its gear master.

The RMC provides both relative gearing, which defines only the rate at which the slave moves

based on the rate of the master, and absolute gearing, which defines exactly the position of

the slave based on the value of the master.

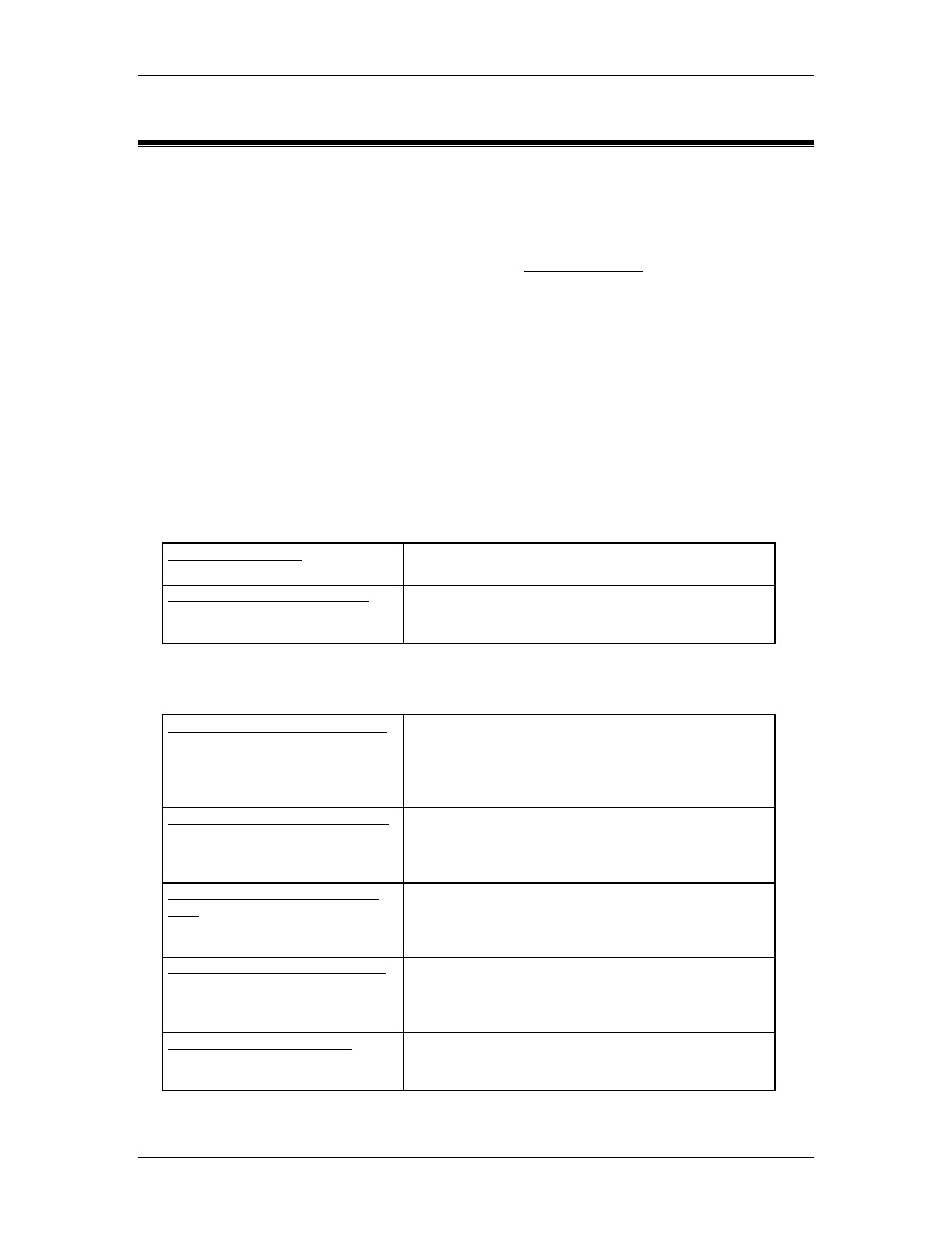

Gearing Commands

The RMC offers the following gearing commands:

Absolute Gearing Commands

Absolute gearing defines exactly the position of the slave based on the value of the

master. The absolute gearing commands work very well for making an axis follow a

reference input (half axis).

Sets up an absolute linear gearing relationship and

will make the axis follow that relationship.

Sets up an absolute linear gearing relationship for

pressure/force and will make the axis follow that

relationship.

Relative Gearing Commands

Relative gearing defines the rate at which the slave moves based on the rate of the

master.

Gear Pos (Clutch by Rate) (39)

Gears the position of an axis to a master. The

clutching is done such that the slave axis ramps its

target velocity using the acceleration and jerk

parameters until it reaches the synchronized gear

ratio.

Gear Pos (Clutch by Time) (30)

Gears the position of an axis to a master. The

clutching is done such that the gear ratio ramps

from the current ratio to the specified ratio in the

specified time.

Gears the position of an axis to a master. The

clutching is done such that the master and slave

synchronize exactly at the requested positions.

Typically used in flying-cutoff type applications.

Gear Vel (Clutch by Time) (31)

Gears the velocity of an axis to a register. The

clutching is done such that the gear ratio ramps

from the current ratio to the specified ratio in the

specified time.

For very advanced gearing applications. It is

intended to be used in user programs along with

mathematical calculations.

Gearing with Motion Limits Commands

deltamotion.com

109