Command request and acknowledge bits – Delta RMC151 User Manual

Page 423

6 Communication

Discrete I/O augments the communications of the RMC. Discrete I/O is typically faster and

more deterministic than the communications, and is therefore well-suited for starting a

sequence in one or more RMCs at a specific time.

Some example uses of discrete I/O for communications:

•

Start or Stop User Programs

Use the Program Triggers to start and stop User Programs based on an input.

•

Affect flow of User Programs

Use inputs in the Conditional Jump link type to make link conditions that affect the

flow of the User Programs.

•

General input and output

Turn outputs on and off from within User Programs and use inputs in Expressions.

For details on using these features, see the following topics:

•

•

Discrete I/O Modules

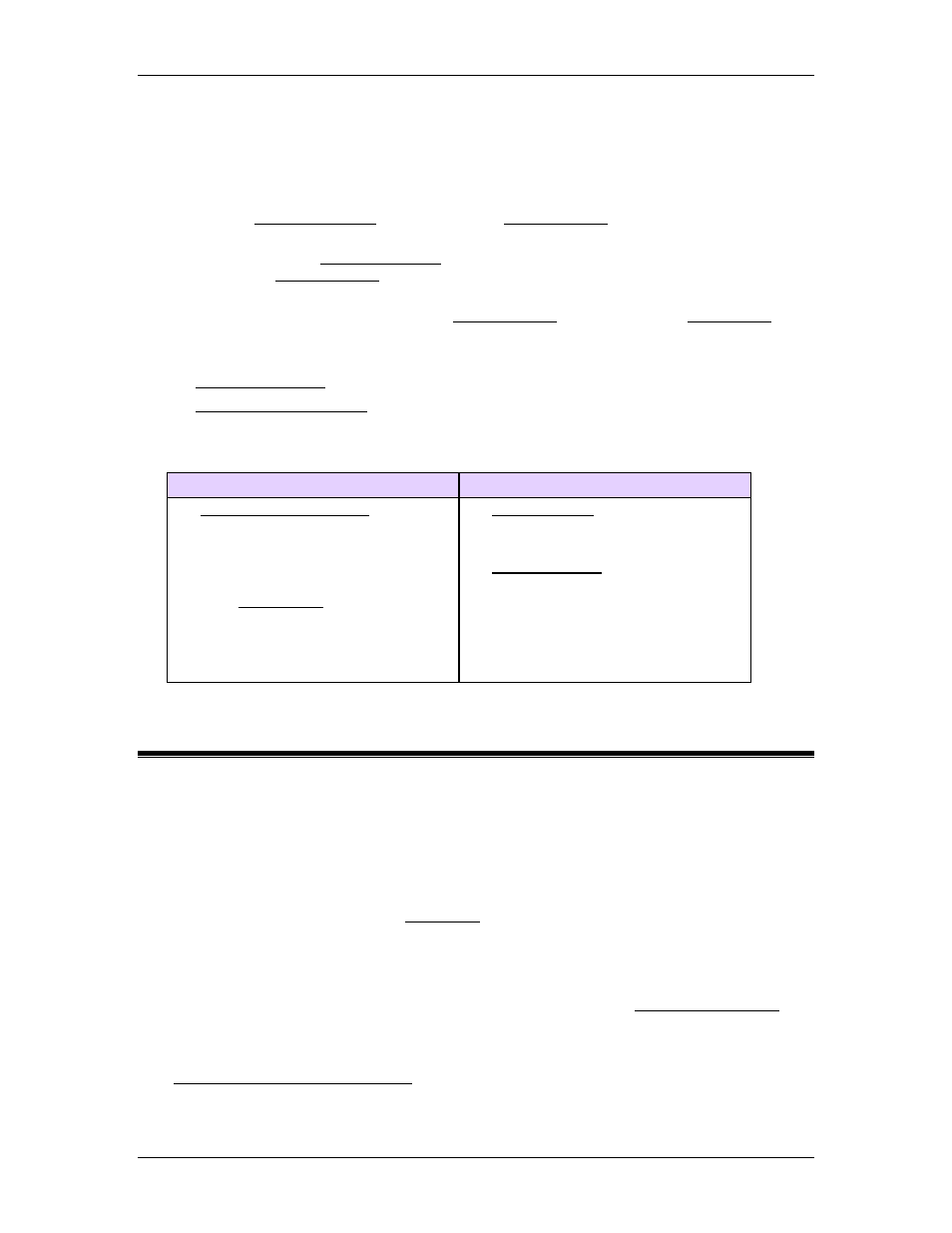

The following discrete I/O modules are available on the RMCs:

RMC70

RMC150

•

8 discrete I/O, 12-24VDC,

individually programmable as

inputs or outputs.

•

Axis Module DI/O

Each axis module contains one

discrete Fault Input and one

discrete Enable Output. These are

intended for specific purposes, not

as general-use discrete I/O.

•

8 discrete outputs, 5-24VDC.

18 discrete inputs, 5-24VDC.

•

RMC150E CPU I/O

The RMC150E CPU includes:

2 discrete inputs, 12-24VDC.

2 discrete outputs, 12-24VDC.

6.7. Command Request and Acknowledge Bits

The Command Request and Command Acknowledge bits provide synchronization of

commands and status information between the PLC and RMC. Using these bits is optional.

These bits are available only when writing commands directly to the Command Area registers

from an external host controller, such as a PLC.

For many PLC applications, they are very important. When reading status bits and status

registers, these bits let the PLC know that the data being requested is valid. For example,

after a Move command is issued, the In Position status bit is not valid until the RMC has

informed the PLC that it received the command. The RMC does this by matching the Command

Acknowledge bit to the Command Request bit.

PROFIBUS

These bits are available only for the Basic/Enhanced modes. The PROFIBUS I/O mode

does not use the command area, and instead uses a simple method to handshake data

between the PLC and RMC.

For details on using the REQ and ACK bits with PROFIBUS Basic/Enhanced modes, see the

Basic/Enhanced PROFIBUS Modes topics.

Serial (RS-232/485) and Ethernet

deltamotion.com

403