Delta RMC151 User Manual

Page 209

3 Controller Features

RMC150: SSI Module, Universal I/O module

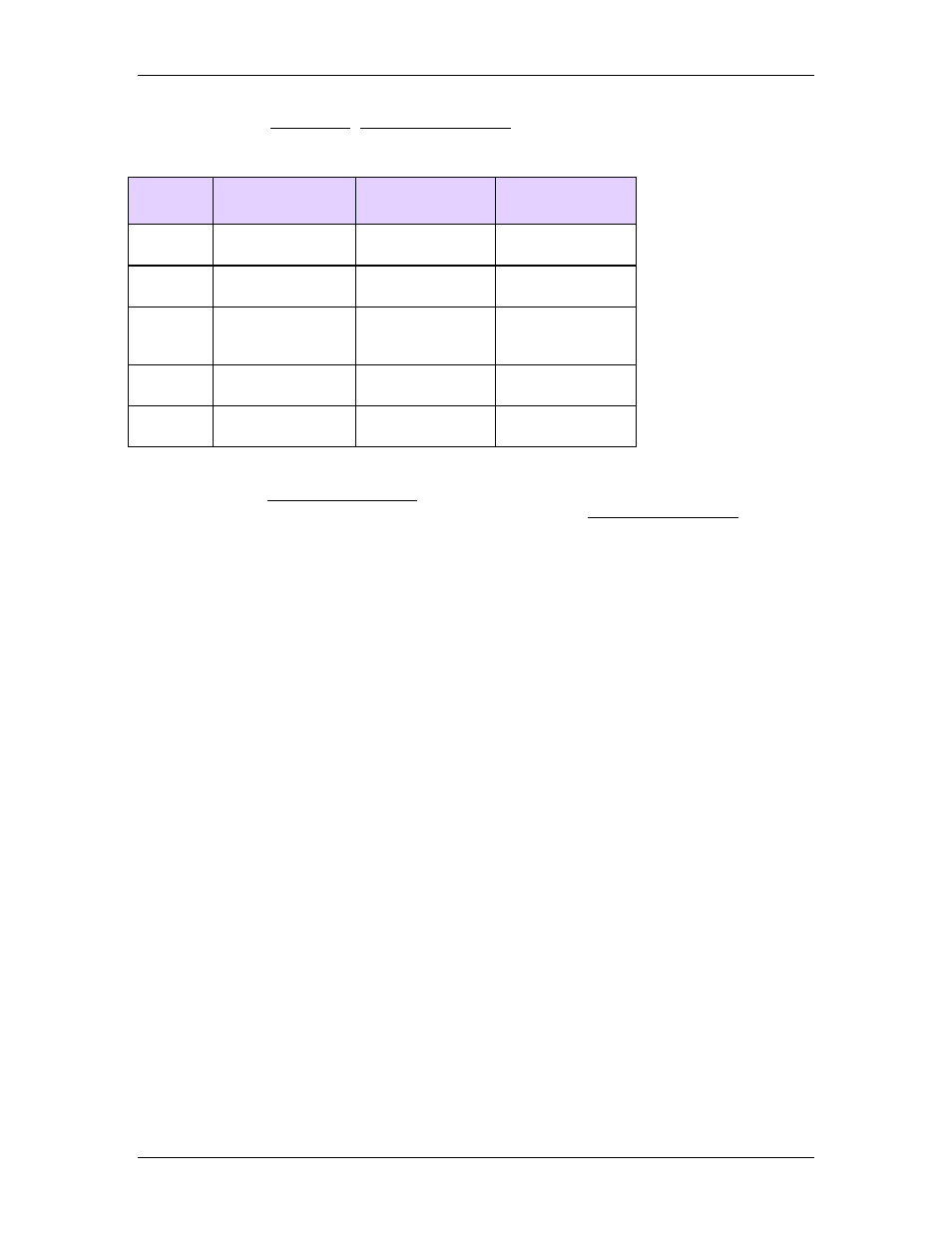

The RMCs provide the following SSI options:

SSI

Options

RMC70

MA Module

RMC150

SSI Module

RMC150

UI/O Module

Data

Bits

8 to 32

8 to 31

8 to 32

SSI

Format

Binary or Gray

Code

Binary or Gray

Code

Binary or Gray

Code

SSI

Errors

None, all zeros,

all ones, or bit

21

None, all zeros,

all ones, or bit

21

None, all zeros,

all ones, or bit

21

Clock

Rates

150, 250, and

375 kHz

230 or 921kHz

250kHz, 500kHz

or 971kHz

Wire

Delay

n/a

n/a

available

Universal I/O Module SSI Options

The RMC150 Universal I/O module supports additional SSI features, such as monitor

mode and inter-RMC communications. For details, see the Universal I/O module topic

Synchronized SSI for Linear Magnetostrictive Transducers

When using magnetostrictive SSI transducers, it is highly recommended that a

synchronized SSI transducer be selected. This ensures that the time between position

samples matches the control loop time of the RMC controller. If the transducer is not

synchronized, the sample time may not match and will adversely affect control. When the

sample time does not match the loop time it introduces jitter to the position

measurement which gets worse as the axis speed increases. Make sure to specify that the

transducer be of the synchronized type.

Synchronized SSI is not an issue for rotary encoders.

SSI Advantages

SSI transducers and absolute encoders offer the following advantages:

•

High resolution. Down to 1 μm (approx. 0.00004") for linear SSI transducers.

•

Noise immunity

•

Cost effective data transfer (only one 5-wire cable with shield is needed)

•

Transmission rate independent of data length and resolution

•

Transmission over long distances

•

Direct connection to the RMCs SSI axis module

Data Format

To read an SSI position, the RMC sends clock pulses to the transducer and the SSI device

returns the data as follows:

1. The SSI channel sends the first clock pulse by setting the Clock signal low, then high.

2. On the first rising edge of the Clock signal, the SSI transducer returns the most-

significant bit of the data on the Data line.

3. The SSI channel sends the second clock pulse by setting the Clock signal low, then

high. When the Clock signal goes high, the SSI channel samples the bit on the Data

line. When the SSI device sees the clock signal go high, it places the second bit of

data on the Data line.

4. This continues until all bits have been clocked and sampled.

deltamotion.com

189