Delta RMC151 User Manual

Page 197

3 Controller Features

Custom No Transducer Error Bit

The Custom No Transducer bit in the Custom Error Bits register can be written to from

the user program to provide an error indication. Setting the Custom No Transducer Error

bit will result in the No Transducer axis error bit being set, which will then halt the axis

according to the No Transducer Auto Stop setting.

For example, in an application that controls to the average position of multiple

transducers, if any of the transducers receive a transducer-related error, the control axis

should halt. The user program that calculates the average position can set the No

Transducer bit if any transducer errors in the reference axes have occurred. The

Transducer OK axis status bit is a simple method of determining whether any transducer-

related errors have occurred.

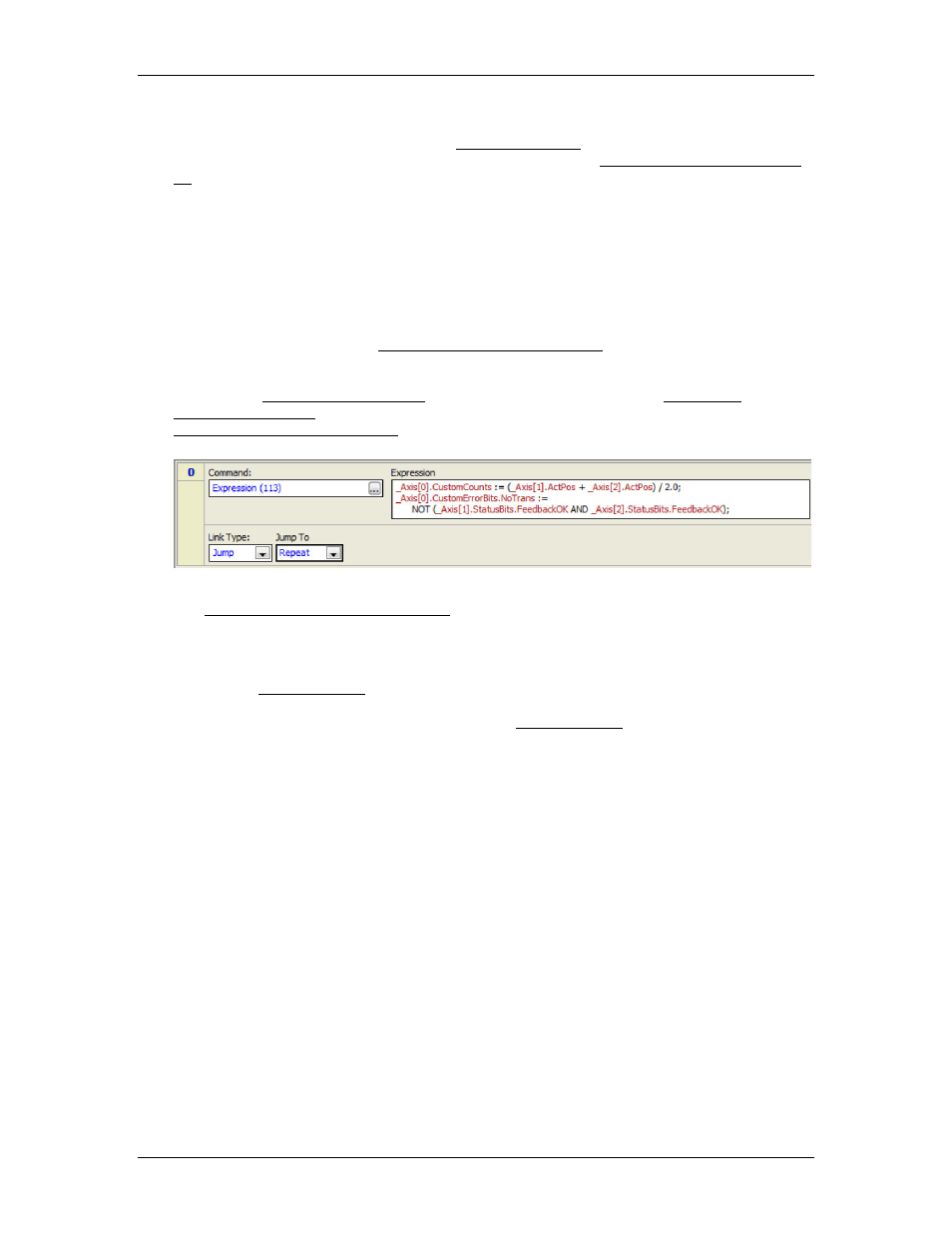

Below is a method using the Custom No Transducer Error bit. In this example, Axis 0 is

the control axis with custom feedback. The feedback is calculated as the average position

of the Axis 1 and Axis 2 reference axes. If the transducer of either reference axis receives

an error, its Feedback OK status bit will turn off and the control axis' Custom No

Transducer Error bit will be set. As soon as the errors in the reference axes clear, the

Custom No Transducer Error bit will also clear, allowing the axis to perform closed-loop

motion.

Custom Feedback Auto-Fault Mode

The Custom Feedback Auto-Fault Mode axis parameter defines certain cases in which the

No Transducer or Prs/Frc No Transducer error bit will automatically be set. The following

options are available:

•

Missed Update (default setting)

If the Custom Counts register is not written to in a given loop time, the No

Transducer error will be set. This is the preferred mode for most applications. In

this mode, you should make sure that the Custom Counts register is written to each

loop time.

•

PROGRAM Mode

If the controller is in PROGRAM mode, the No Transducer error will be set. This

mode may be useful in situations where you do not need to update the Custom

Counts very often, but you do wish to halt the axis if the program that updates the

Custom Counts is stopped due to the controller entering PROGRAM mode.

•

Disabled

The No Transducer error will not be set by any of the above options. In this mode,

the updating of the Custom Counts register is not monitored in any way. This could

be used in cases where the Custom Counts register is being modified from an

external device, such as a PLC.

Additional Error Handling Considerations

In certain Custom Feedback applications cases, such as switching feedback on the fly, it

may be normal for one of the reference axes to receive a transducer error. If you want

the user programs to continue operating, make sure the tasks do not stop when the

reference axis halts due to the error. This can be set in the Programming Properties, on

the Halts page.

deltamotion.com

177