Delta RMC151 User Manual

Page 30

RMC70/150 and RMCTools User Manual

j. On the Controller menu, click Update Flash. This stores your changes in the RMC

even in the event of a power outage.

k. Press Ctrl+S to save the project.

6. Connect an Actuator

Note:

Read this section completely before executing any commands on the RMC.

a. Important: Turn off power to the RMC and the actuator before connecting any wires!

b. For each axis you wish to connect an actuator to, wire it to the RMC according to the

Wiring topic.

c. After wiring, re-apply power to the RMC, the feedback device, and the actuator.

Note:

To test the actuator, you will supply a Control Output voltage from the RMC to the

actuator. Before doing this, make sure that the axis may safely move in either

direction!

d. In RMCTools, in the Project pane, click the RMC controller.

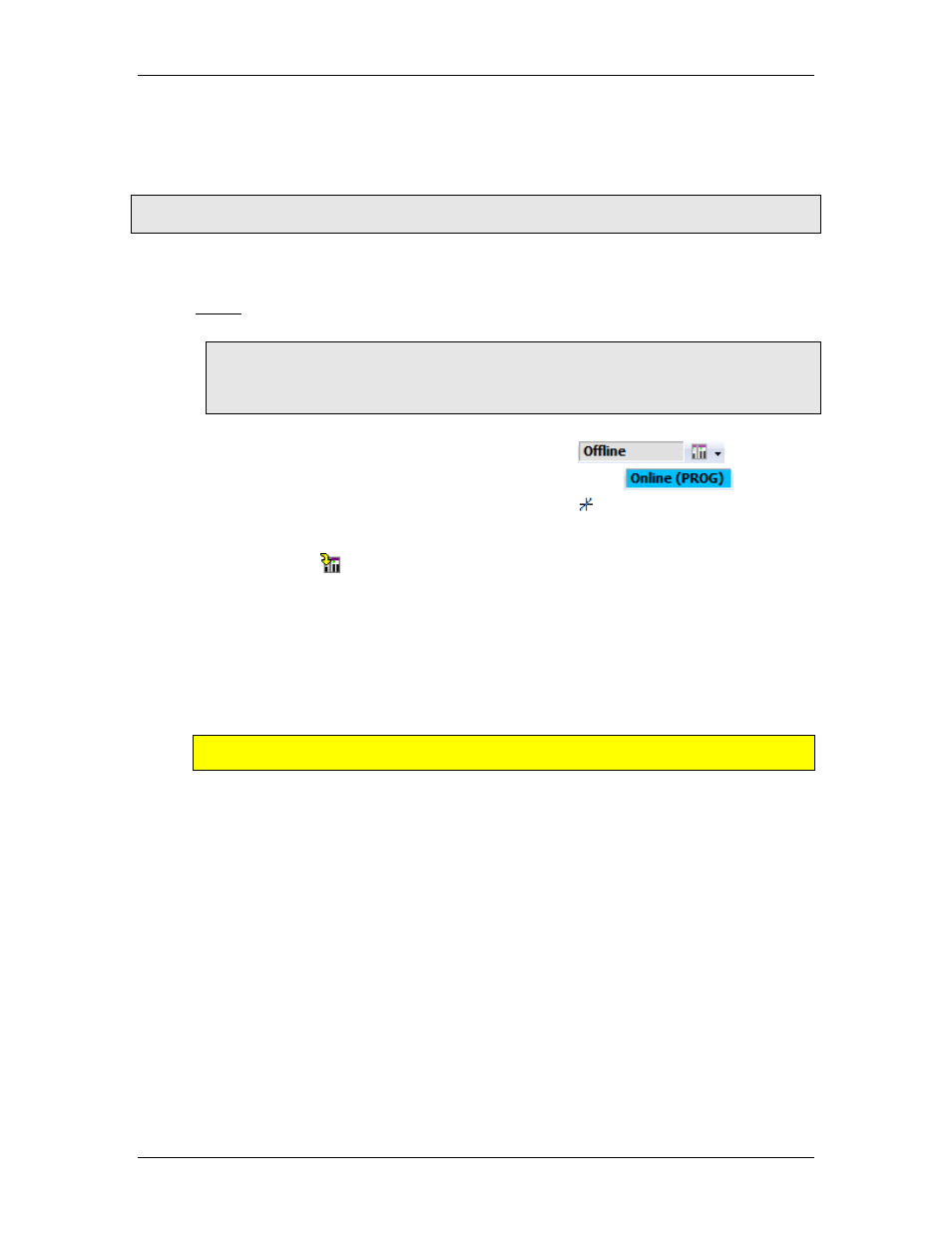

e. On the RMCTools toolbar, click the Controller button

and choose

Go Online. The toolbar will indicate that RMCTools is online

.

f. On the RMCTools toolbar, click the Axis Tools button .

g. In the Axis Parameters pane, on the All tab, expand the Simulate section and

verify that Simulate Mode is cleared. If you make changes, you must click the

Download button or press Ctrl+D to apply the changes to the RMC.

h. Now you must enable the axis. In the Command Tool, in the Cmd box, type "Enable",

then choose Enable Controller (7) from the list. Click Send.

i. In the Axis Tools, in the Axis Status Registers pane, on the Basic tab, verify that

the Control Output for the axis is 0 (zero).

j. Turn on power to the motor or hydraulics for the axis being set up. Note that after

starting, it is normal for the axis to drift slowly.

k. In the Command Tool, do the following steps to apply 0.1 V to the axis Control

Output:

l. Caution: Use the Direct Output command with extreme caution! It disables the

safety features of the RMC!

•

Double-click the Cmd box, type "D" and choose the Direct Output (9)

command.

•

Set the Output to 0.1 V.

•

Set the Ramp Rate to 100 V/s.

•

Click Send Command.

•

Enter 0 in the Output box. This will allow you to quickly issue a Direct Output

Command with 0 drive in the next steps.

m. Verify that the Control Output register for the axis is at 0.1 V.

n. Observe the Actual Position register (on the Basic Position tab) and note whether

it is increasing or decreasing. One of three things could have happened at this point:

•

The actuator moved and the Actual Position increased.

In this case you are ready to go to the next section and set the Scale.

•

The actuator moved and the Actual Position decreased.

In this case, first verify that the wiring is correct. If it is not, fix it and repeat

the process. If it is, invert the Output Polarity to reverse the direction:

m.

10

Delta Computer Systems, Inc.