Delta RMC151 User Manual

Page 130

RMC70/150 and RMCTools User Manual

The Track commands provide gearing, with limits on the position, velocity, acceleration

and jerk. These commands are useful for smoothly tracking a signal containing noise or

step-jumps, or for gearing to another position while not exceeding specified motion limits.

Continuously tracks the specified master register.

The axis position is limited by the positive and

negative travel limits, and the specified velocity,

acceleration, and jerk limits.

Continuously tracks the specified master register.

The axis will be controlled using the I-PD

algorithm. The axis position is limited by the

positive and negative travel limits and the

specified velocity.

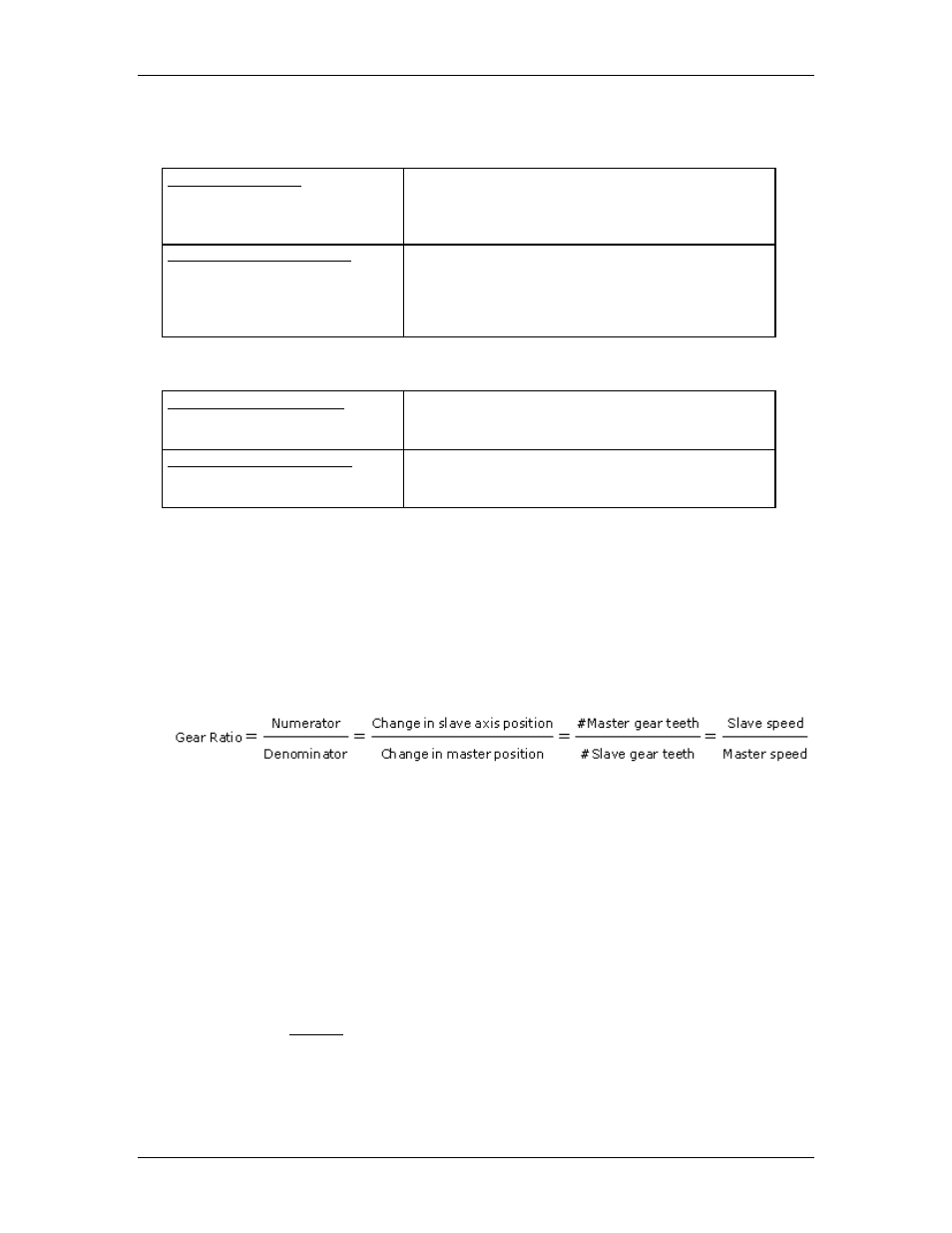

Gear Modifying Commands

These commands modify an existing gearing relationship.

Superimposes a move of the requested distance

onto the currently-geared axis while the master

moves the specified distance.

For very advanced gearing applications. It is

intended to be used in user programs along with

mathematical calculations.

Gear Ratio

The gear ratio specifies the gearing of the axis to its master. To make gearing infinitely

accurate in more applications, most of the RMC gear commands use a Numerator and

Denominator to specify the ratio. For example, if a user has a rotary application and

needs a gear ratio of 1:3, it cannot be represented with a single decimal number.

However, the Numerator and Denominator will represent this accurately and the system

can gear for any number of revolutions without losing the position.

The Numerator is the distance the slave axis travels as the master travels the distance

specified by the Denominator. This relationship is shown below in equivalent equations:

Gear Ratio of Zero (0)

A gear ratio of zero will cause the slave axis to stop. This can be very useful if the axis is

already geared. By specifying a gear ratio of zero and clutching by distance, the slave can

be instructed to stop when the master reaches a certain position.

High Gear Ratios

High gear ratios can cause unstable control. A high gear ratio will cause the slave axis to

move a large distance while the master moves a small distance. Any noise in the master

will be amplified in the motion of the slave axis. In addition, the feedback increments will

be amplified. Try to avoid high gear ratios.

If a high gear ratio cannot be avoided, try to use the lowest noise and highest resolution

feedback possible on the master axis. This will minimize the amplification of the feedback

increments and noise. If the master axis is a control axis, make sure the motion is

smooth and minimize quick changes in velocity. If the master axis is a reference axis,

consider adding filtering to it to reduce noise.

Gear Absolute

The Gear Absolute commands do not use a numerator and denominator. Instead, the

gearing relationship is defined with Master Point A, Master Point B, Slave Point A, Slave

110

Delta Computer Systems, Inc.