Delta RMC101 User Manual

Page 91

Basic Topics 3.4

Using RMCWin

3-41

Scale/Offset Calibration Utility:

1. Obtain the following information:

• Pressure Gauge Scale: This is the pressure at which the RMC will receive its maximum

voltage or current. For example, if the RMC input is configured for a 0 to 5 V transducer, then

you should enter the pressure at which the gauge will return a 5 V signal, even if it can return

more than 5 V. For 4-20 mA gauges, give the pressure at 20 mA.

Note:

The pressure gauges on each end of the hydraulic cylinder or motor should have the

same range.

• Actuator Type: Three configurations are handled by this utility:

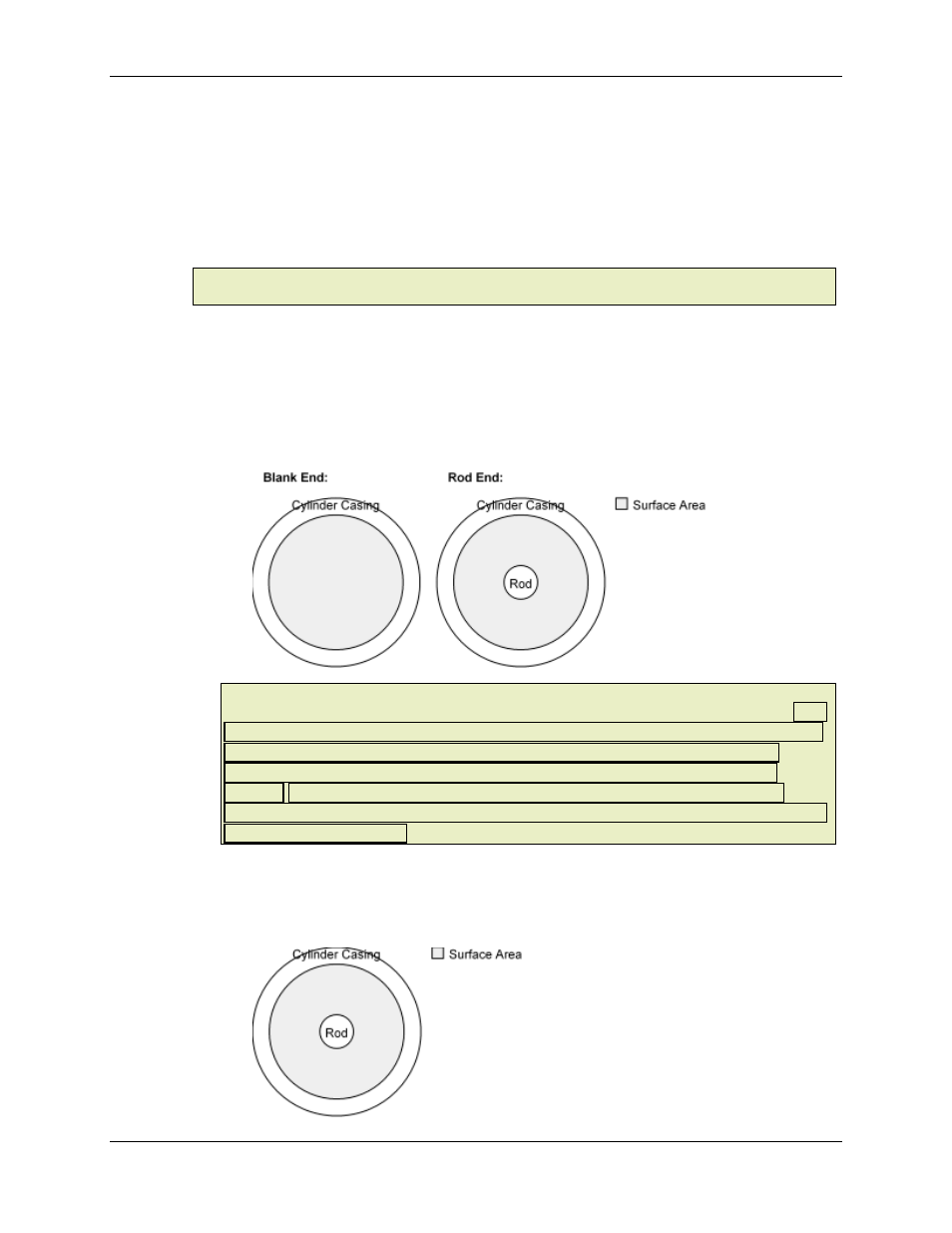

Hydraulic Cylinder with a Single-Ended Rod

In this configuration, the surface area on each side of the piston is multiplied by the

pressure reading to give a resultant force. It is necessary to convert to force units when

using a single-ended rod because equal pressures do not exert an equal force because

the surface areas differ on each side of the piston, as shown below:

Note:

Because the surfaces areas are different for each side of the piston in a hydraulic

cylinder with a single-ended rod, SCALE A and SCALE B are not interchangeable. As a

result, the first channel in the differential pair (channel 0 or 2) must be connected to the

pressure sensor on the blank or cap end of the cylinder, and the second channel

(channel 1 or 3) must be connected to the pressure sensor on the rod end of the

cylinder. If you have wired the sensors in the opposite direction, and prefer not to

change your wiring, then you will need to manually swap SCALE A and OFFSET A with

SCALE B and OFFSET B.

Hydraulic Cylinder with a Double-Ended Rod

In this configuration, the surface area on each side of the piston is multiplied by the

pressure reading to give a resultant force. The following diagram shows how the surface

area is calculated: