Stepper scaling, Stepper scaling -53, 6 stepper scaling – Delta RMC101 User Manual

Page 597

Quadrature with Stepper Output 6.4

Transducer Interface Modules

6-53

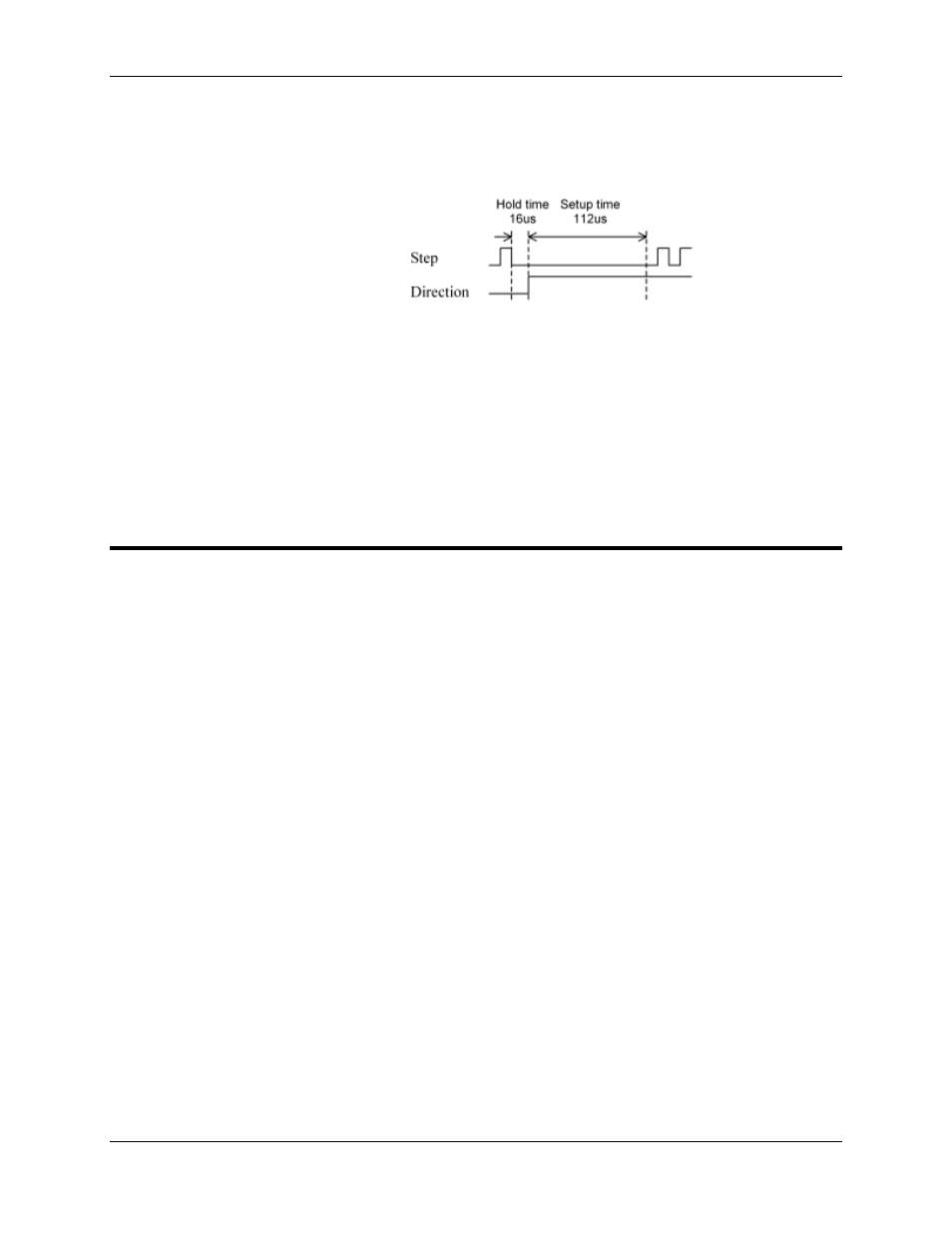

Direction Change Delays

Hold time = 16 us

Setup time = 112 us plus half step

period

See also:

Stepper Overview

Stepper Wiring

Stepper Configuration

Stepper LED Indicators

Stepper Scaling

Stepper Compensation

Homing

6.4.6 Stepper Scaling

Defining the Valid 16-bit Position Range

For general scaling information, see the Scaling Overview topic.

Because the RMC uses 16-bit positions, positions must all fit within a range of 65,536 position

units. Because position units are user definable, and speed control and indexing applications can

get around this limitation, most applications are not limited by this range. See the section below

on defining position units.

Stepper axes use the Coordinate Limit parameter to define the valid range of position units. The

valid Coordinate Limit values extend from 65535 to 0, and the valid position range then extends

from the Coordinate Limit value to the Coordinate Limit plus 65535. Delta recommends using one

of the following two values and ranges:

Coordinate

Limit

Range

0

0 to 65535

-32768

-32768 to

32767

The first uses unsigned position units and the second uses signed position units. Other position

ranges require extra work to use with PLCs.

Translating to and from Position Units

The method of setting up the scale for a stepper axis with quadrature feedback differs

significantly from the scaling of other axis types on the RMC. This was done to better fit the needs

of stepper applications.

The stepper module has two scales. One scale defines the relationship between incoming

quadrature counts and the resultant Actual Position. The second scale defines the relationship