Mdt configuration, Mdt configuration -24, 3 mdt configuration – Delta RMC101 User Manual

Page 568

RMC100 and RMCWin User Manual

6-24

MDT Specifications

6.2.3 MDT Configuration

The RMC supports a wide range of Magnetostrictive Displacement Transducers. To select the

type of the transducer and polarity of the drive output, the following settings can be changed:

• Support for Pulse-Width Modulated or Start-Stop MDTs.

• Support for between 1 and 15 recirculations on PWM MDTs.

• Support for using either edge of a Start-Stop pulse. This is required to support some Balluff

transducers.

• Support for short and long blanking periods. The correct setting of this parameter depends on the

transducer housing type. See the description below.

• Support for reversing the drive output in software.

These settings are set from software; no jumpers are required. Except for the blanking period,

these settings are all in the Configuration word parameter; refer to that help topic for further

details. See the descriptions below for details on the blanking period settings.

Blanking Period

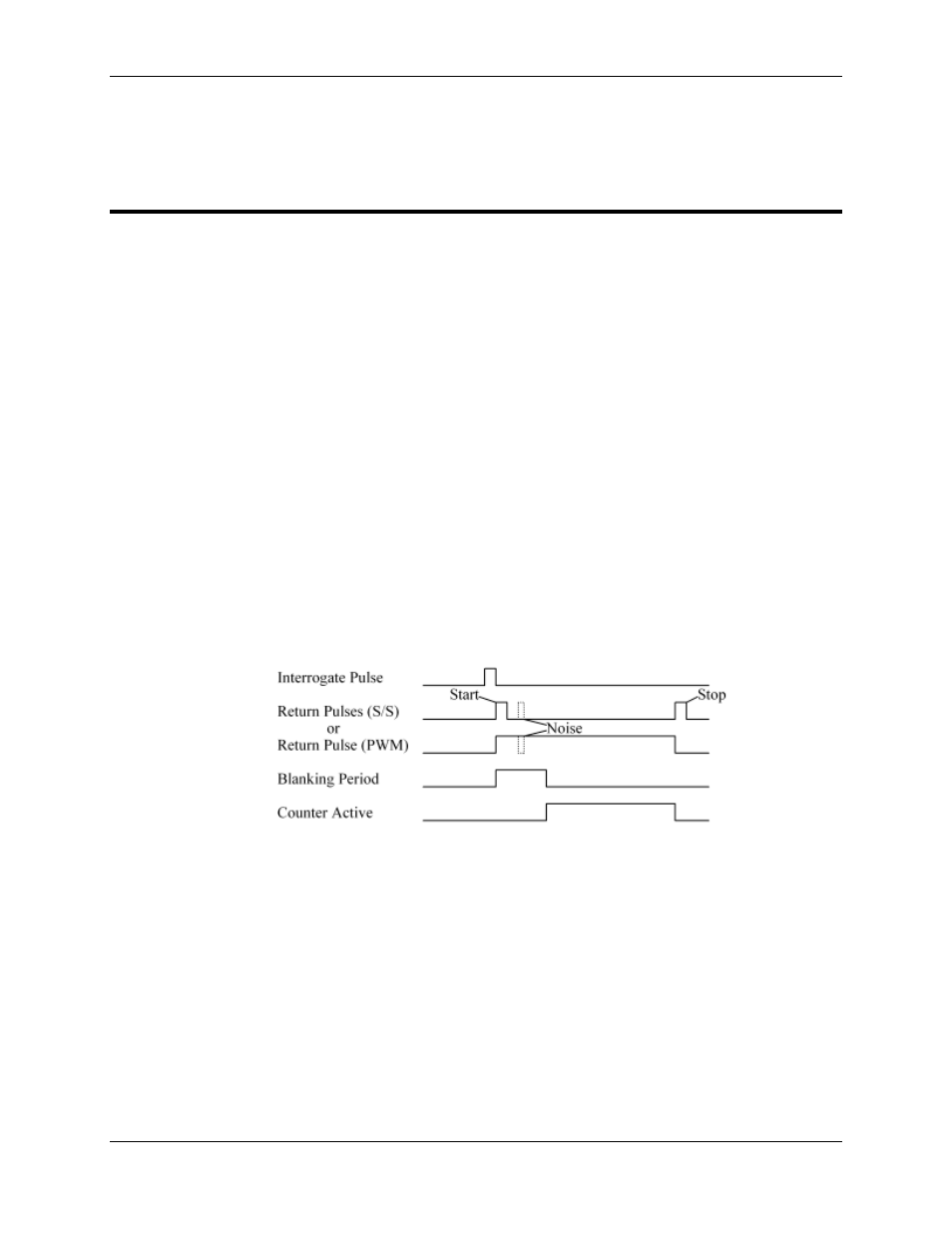

The blanking period determines the amount of time to delay before starting the counter for an

MDT. The time delay begins after the rising edge of the Start pulse on a Start/Stop MDT or the

return pulse on a PWM MDT. Refer to the following diagram:

The reason for the blanking period is to ignore noise that occurs after edges on the Start or PWM

pulse. This was especially a problem with older transducers. As shown in the diagram above,

noise during the blanking period is ignored.

However, the longer the blanking period is, the longer the minimum distance measurable by the

motion controller becomes. That is, if the Stop pulse comes back during the blanking period, it is

not registered, and no position can be read. This becomes a problem only with the newer clevis-

mount transducers (for example, the IP-67 housing type from Temposonics).

Therefore, to allow for this trade-off, the blanking period can be set through RMCWin to be either

5ms (recommended for clevis-mount transducers) or 21ms (recommended for all other

transducers). This setting cannot be changed from a PLC, but must instead be set through

RMCWin and saved in the RMC’s Flash memory.

Therefore, to allow for this trade-off, the blanking period may be configured: