Integral gain (pressure), C.5.8 integral gain (pressure) – Delta RMC101 User Manual

Page 839

Appendix C: Parameter Field Reference

C-69

Note:

Use positive Feed Forward and Gain values if the pressure increases in the extend

direction, and negative values if the pressure increases in the retract direction.

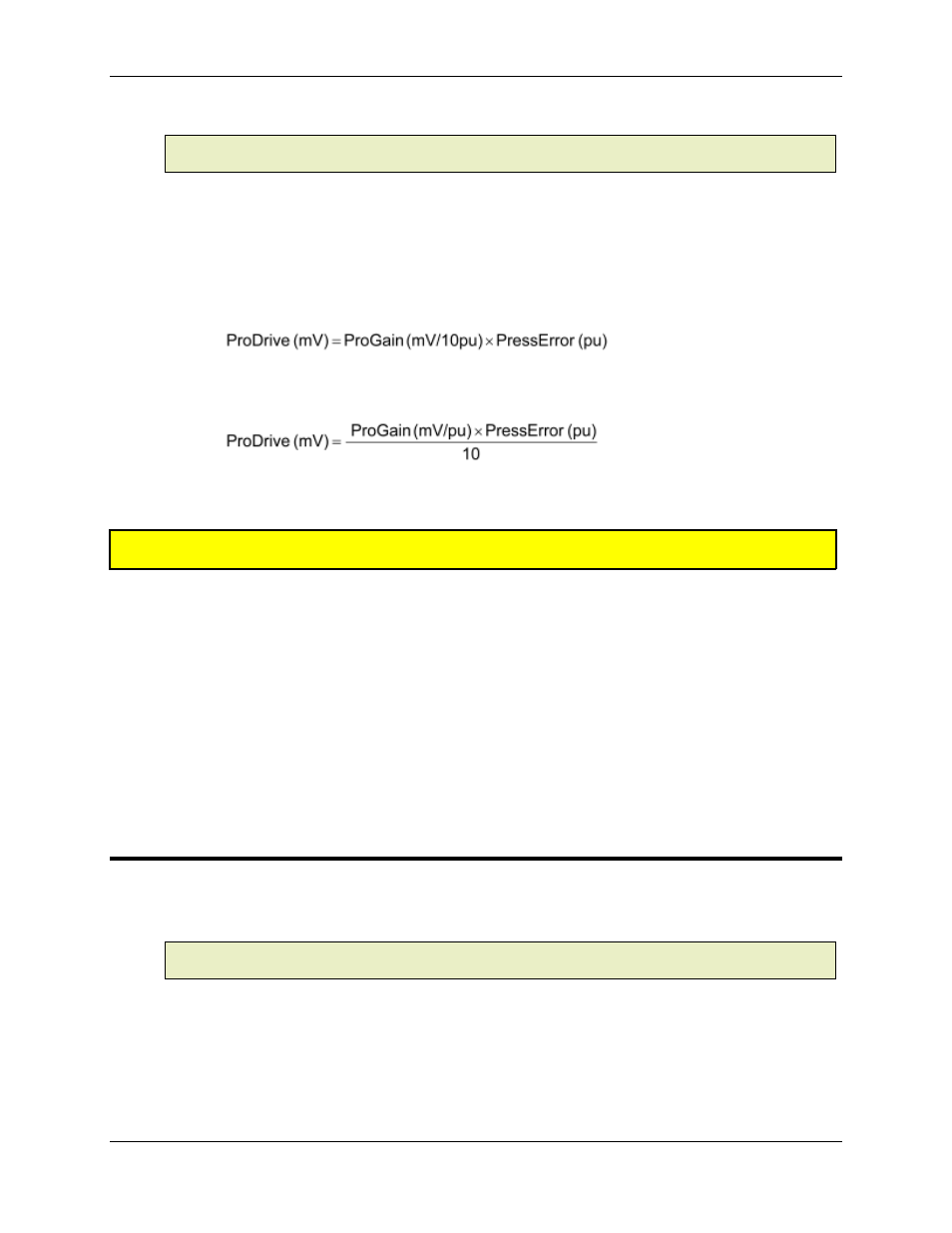

The Proportional Gain controls how much drive is generated proportional to the Pressure Error.

The Pressure Error is defined as the Target Pressure minus the Actual Pressure. The units on the

Proportional Gain is millivolts per 10 units of Pressure Error.

The Proportional Drive is defined as follows:

Or more simply:

where pu is pressure units.

CAUTION:

Increase the Proportional Gain gradually. Excessive gain can cause oscillation that could

cause damage or injury.

Think about this:

Internally, the motion controller must compare the error between the Target and Actual Pressures

with error limits to keep values from overflowing. The error limit is the error at which full drive (10

volts) will occur. This internal error limit is calculated as follows:

Error Limit = 1,000,000 / Proportional Gain

Therefore, if the Gain is set to 100, the Error Limit will be 10,000, which means any error greater

than 10,000 will be treated as an error of 10,000 and the Overdrive error bit will be set in the

Status word.

C.5.8 Integral Gain (Pressure)

Default: 1

Range: -32768 to 32767

Note:

Use positive Feed Forward and Gain values if the pressure increases in the extend

direction, and negative values if the pressure increases in the retract direction.

The Integral Gain is used to control the amount of drive provided by the integrator. The integrator

adds the pressure error to an accumulator every millisecond. The Integral Gain should be

adjusted after the Feed Forwards have been set to optimal values. Using the integrator before the

feed forwards have been set properly will cause the system to overshoot the target pressure. We

recommend that you set the Integral Gain to a value of at least 50.

Integral Gain is defined as: