Delta RMC101 User Manual

Page 248

RMC100 and RMCWin User Manual

4-62

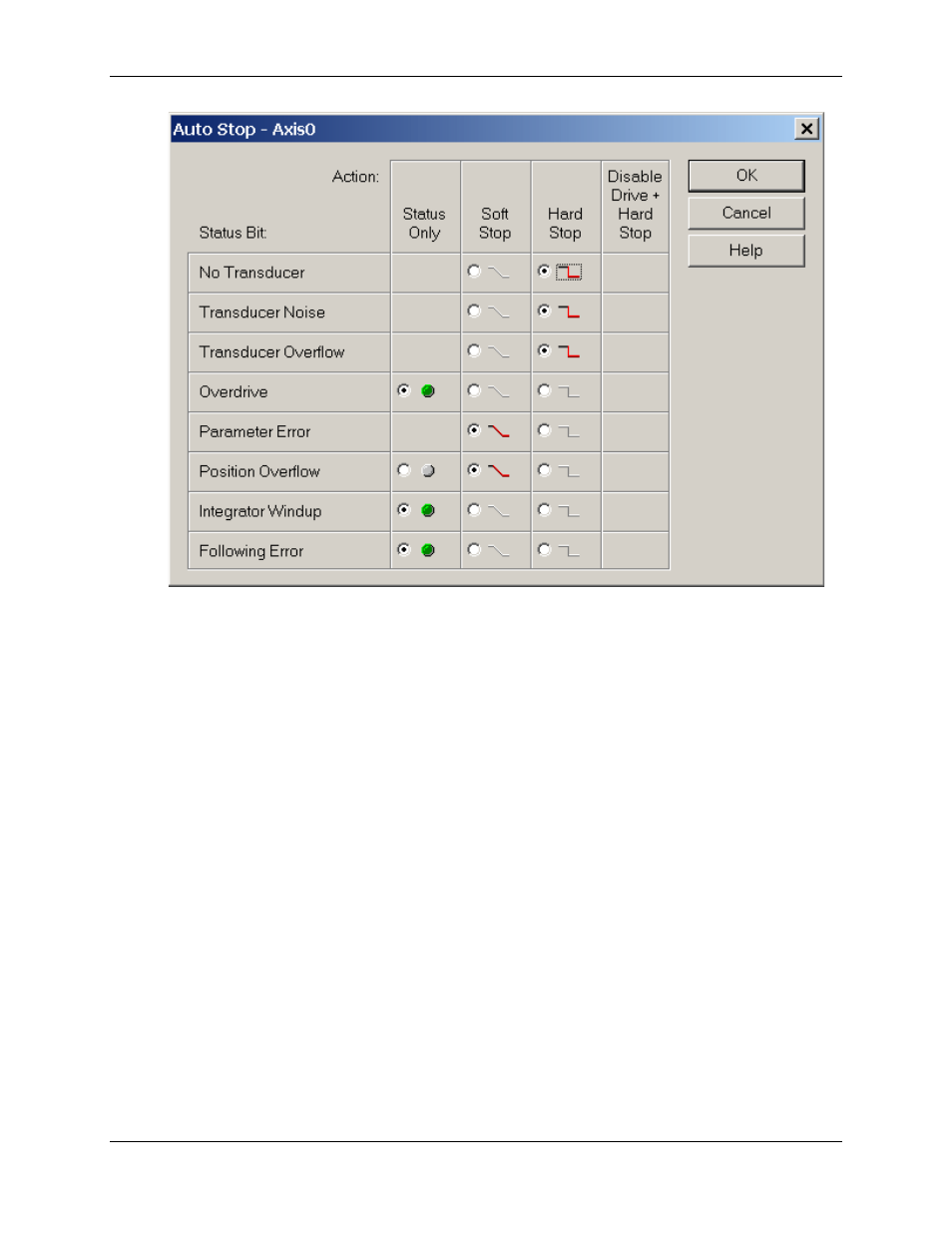

• On most systems, it is preferable to have any axis errors cause a Soft or Hard Stop for safety.

Additionally, Soft Stops are often desirable because they slowly stop the axis. A Hard Stop

immediately puts the drive output to 0 volts, which in some cases can cause a sudden (and

potentially dangerous) jerk in the system. Carefully consider your system requirements before

determining how to set the Auto Stop bits. In this case, all the Auto Stops are set to Soft Stop.

Clicking OK exits the window and issuing a P command initializes the axis with these

parameters.

• The In Position, At Pressure and Following Error parameters should also be set properly.

o

The In Position parameter specifies the size of the window in which the axis is considered to

be in position. Once the axis is in this window, the In Position bit is turned on. This is useful

for determining whether the axis has reached the commanded position. In this example, the

axis is considered to be in position when it is within 0.050 inches, so the In Position

parameter is set to 50.

o

The At Pressure parameter is similar to the In Position parameter, but is for the differential

pressure axis. In this example, it is set to 50, which is 50 lbs.

o

The Following Error parameter determines how large the difference between the Target

Position and Actual Position can get before the Following Error bit is set in the Status word.

Normally, this parameter is set to greater than the worst-case following error to avoid

unnecessarily causing an error. In this example, the Following Error parameter is set to 250

(0.25 in.).

• The system is now ready to be used for more complicated commands, such as speed control,

gearing, splines, synchronized moves, etc.