Delta RMC101 User Manual

Page 285

Digital I/O 5.1

Communications

5-35

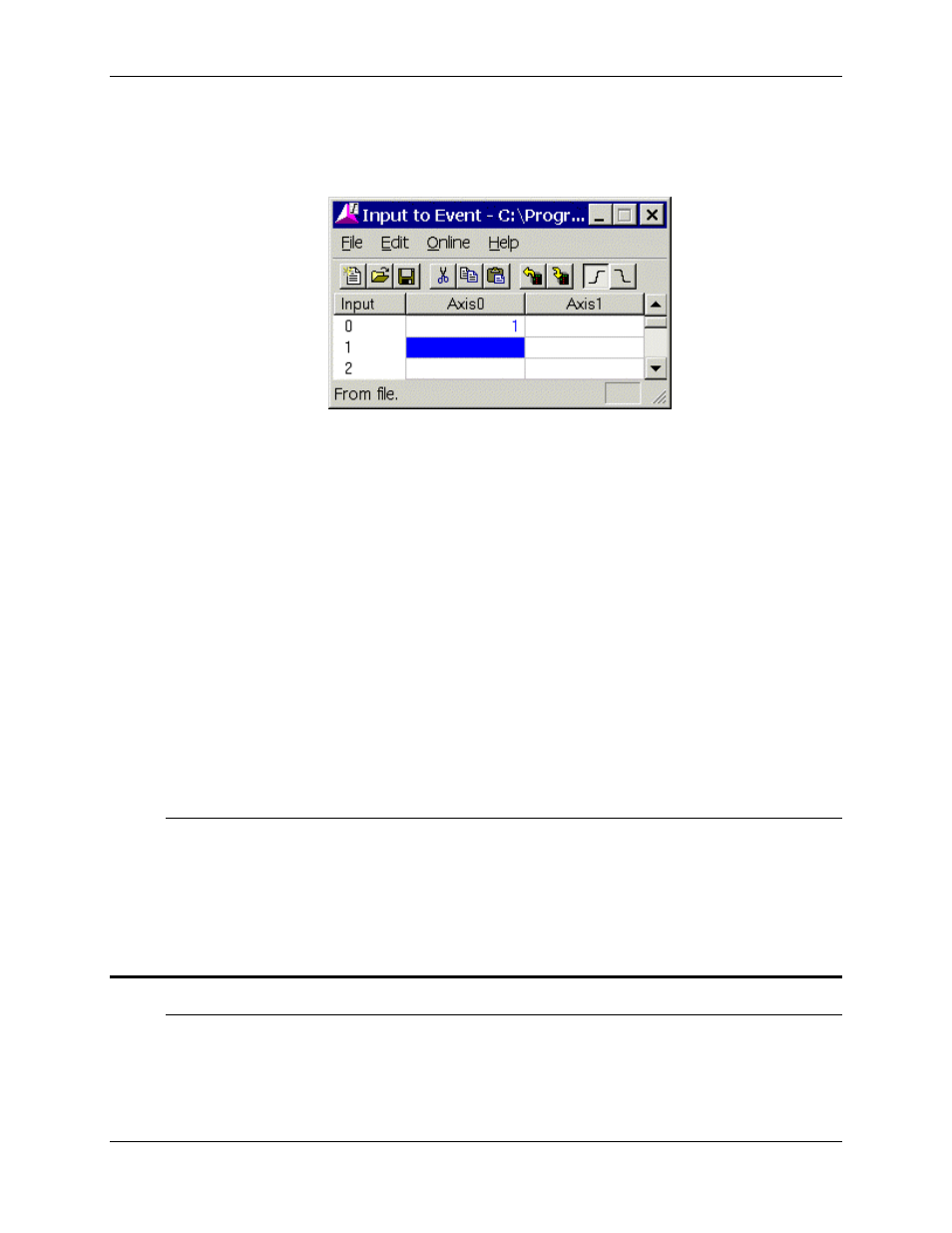

3. Program the Input to Event Table

The final step is to cause DI/O input 0 to trigger the event sequence shown. This is done with the

following simple Input to Event table:

This single table entry causes axis 0 to start the event sequence beginning with step 1 whenever

DI/O input 0 has a rising edge.

4. Configure the RMC Communication

The steps required for this procedure are described in the Implementation section of this Technical

Brief. For this application, you should not need to use (1) inverted inputs, (2) inverted outputs, (3)

counters, (4) single-axis inputs, (5) non-linked inputs, or (6) user-controlled outputs.

5. Wire, Test, and Tune the System

The system should be wired as described in the design above. Test the functionality of the final

system, and finally tune the system as described in the RMCWin online help.

Reference

Throughout this technical note, references are made to RMCWin online help index entries. To

obtain the RMCWin software package, contact Delta Computer System’s web site

(www.deltacompsys.com).

5.1.6.9 Technical Brief: Using the RMC Discrete I/O Parallel Position

Mode

Abstract

The RMC-DI/O is capable of sophisticated motion control using small and inexpensive

Programmable Controllers with simple discrete I/O. An RMC with a DI/O communication interface

is capable of four discrete I/O interfaces: Command Mode, Input to Event Mode, and Parallel

Position Mode. Of these four communication modes, Parallel Position mode is easiest to use for

applications in which an axis must be able to move to numerous—perhaps calculated—positions.