Delta RMC101 User Manual

Page 275

Digital I/O 5.1

Communications

5-25

Parallel Event

Mode

• Up to four axes may be

commanded at once

• PLC or thumb-wheel

switches may be used

• Allows use of Event

Control feature

• Requires parallel inputs

• Returns only a Halted

Bit—indicating an error

has occurred—and an In

Position Bit per axis

• Sequence must be pre-

programmed in Event

Control

Input to Event

Mode

• Does not require a PLC

• Multiple axes may be

given commands from a

single input

• Returns only a Halted

Bit—indicating an error

has occurred—and an In

Position Bit per axis

• Issues only Start Event

commands

Parallel

Position Mode

• Any position can be

moved to in a single

PLC scan

• Any open loop drive can

be triggered in a single

PLC scan

• Multiple profiles can be

selected for any move

• Requires a PLC

• Returns only a Halted

Bit—indicating an error

has occurred—and an In

Position Bit per axis

• Issues only Go and Open

Loop commands

• Gives commands to only

one axis per scan

Implementation

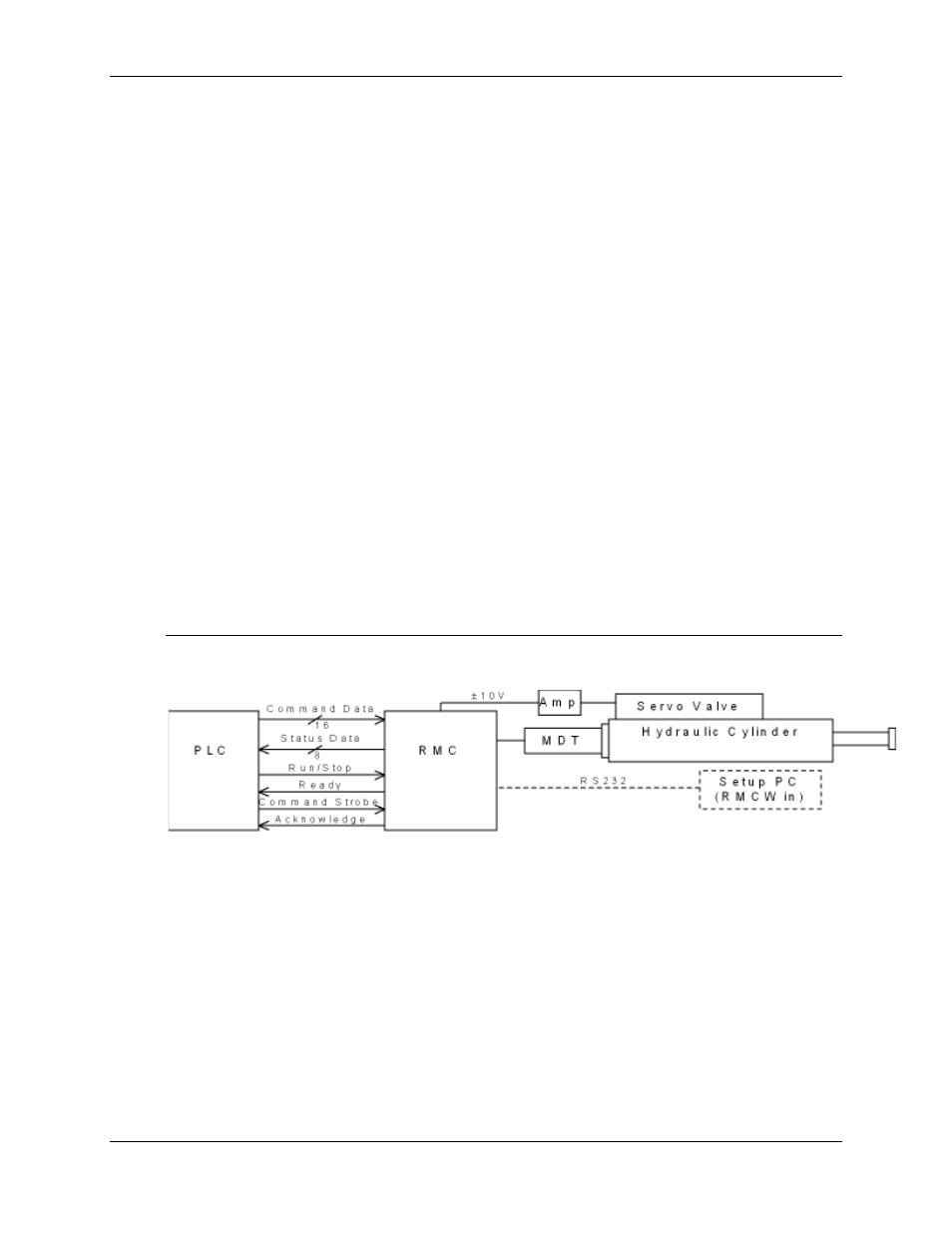

The following diagram shows the electrical control connections of a single-axis hydraulic system

using RMC-DI/O in Command Mode (the PC and its RS232 cable are needed only during setup):

This document discusses only the connections between the Programmable Controller and the

RMC. For details on the transducer and drive wiring, look up Wiring Notes in the RMCWin index.

The RMC accepts commands of up to 32 bits and returns 16-bit data words. However, because it

has only half that number of inputs and outputs, an extra input and output on the RMC are used

to strobe half of the data at a time. The following timing chart and accompanying list of steps

illustrate the sequencing of Command Mode: