Delta RMC101 User Manual

Page 278

RMC100 and RMCWin User Manual

5-28

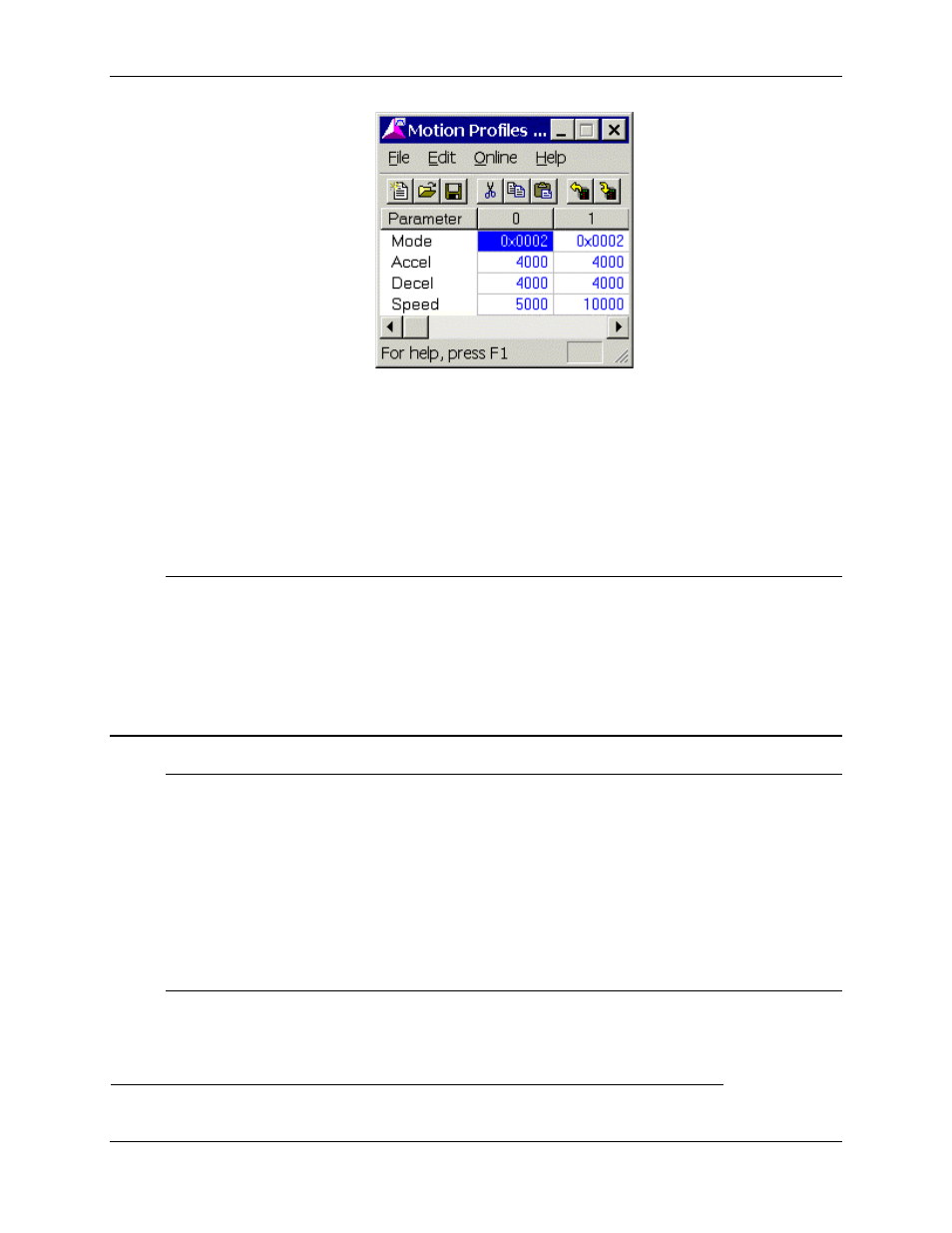

The ’r;2’ in the Mode field indicates that the acceleration and deceleration are given as distances.

For details on the motion profile table, look up Profiles in the RMCWin online help.

This profile table and the tuning parameters can either be stored in the RMC’s Flash memory, or

stored in the Programmable Controller and downloaded using the Set Parameter commands.

We’ll assume they are stored in the Flash. See the Set Profile and Set Parameter topics in the

RMCWin online help for details on setting these values from the Programmable Controller.

Reference

Throughout this technical note, references are made to RMCWin online help index entries. To

obtain the RMCWin software package, contact Delta Computer System’s web site

(www.deltacompsys.com).

5.1.6.8 Technical Brief: Using the RMC Discrete I/O Input to Event

Mode

Abstract

The RMC-DI/O is capable of sophisticated motion control using small and inexpensive

Programmable Controllers with simple discrete I/O. An RMC with a DI/O communications

interface is capable of four discrete I/O interfaces: Command Mode, Input to Event Mode, and

Parallel Position Mode. Of these four communication modes, Input to Event mode is the simplest

for many repetitive-process applications; many applications may not require a programmable

controller.

This technical brief will compare the four discrete I/O interfaces of the RMC100 product-line,

describe implementing Input to Event Mode, and finally provide a sample application using Input

to Event Mode.

DI/O Communication Mode Comparison

The following chart lists the advantages and disadvantages of each communication mode. Each

word or phrase in bold print appears in RMCWin’s online help index.

Interface

Mode

Advantages

Disadvantages

Input to

• Does not require a PLC

• Returns only a Halted