Delta RMC101 User Manual

Page 243

Position/Pressure Control 4.12

Controller Features

4-57

• Notice that there is some overshoot when the pressure ramps up and down. This is because the

rate of change in pressure is high. During normal operation, the rate should be lower. The

system is tuned for a high rate because a system stable at a high rate will generally be stable at

a lower rate. The converse is not true, i.e. a system tuned for a low rate will not necessarily be

stable at a higher rate.

• If the rate of change in pressure is changed (i.e. the ramp time or commanded pressure is

changed) the feed forwards may also need to be changed.

• The tuning of the transition in this case was unusually simple because "Calculate ramp time"

was selected in the Mode word of Event Step 4 (step 4 sets up the pressure before the

transition). The RMC automatically calculates a ramp time that will work well. However, some

applications require a specific ramp time.

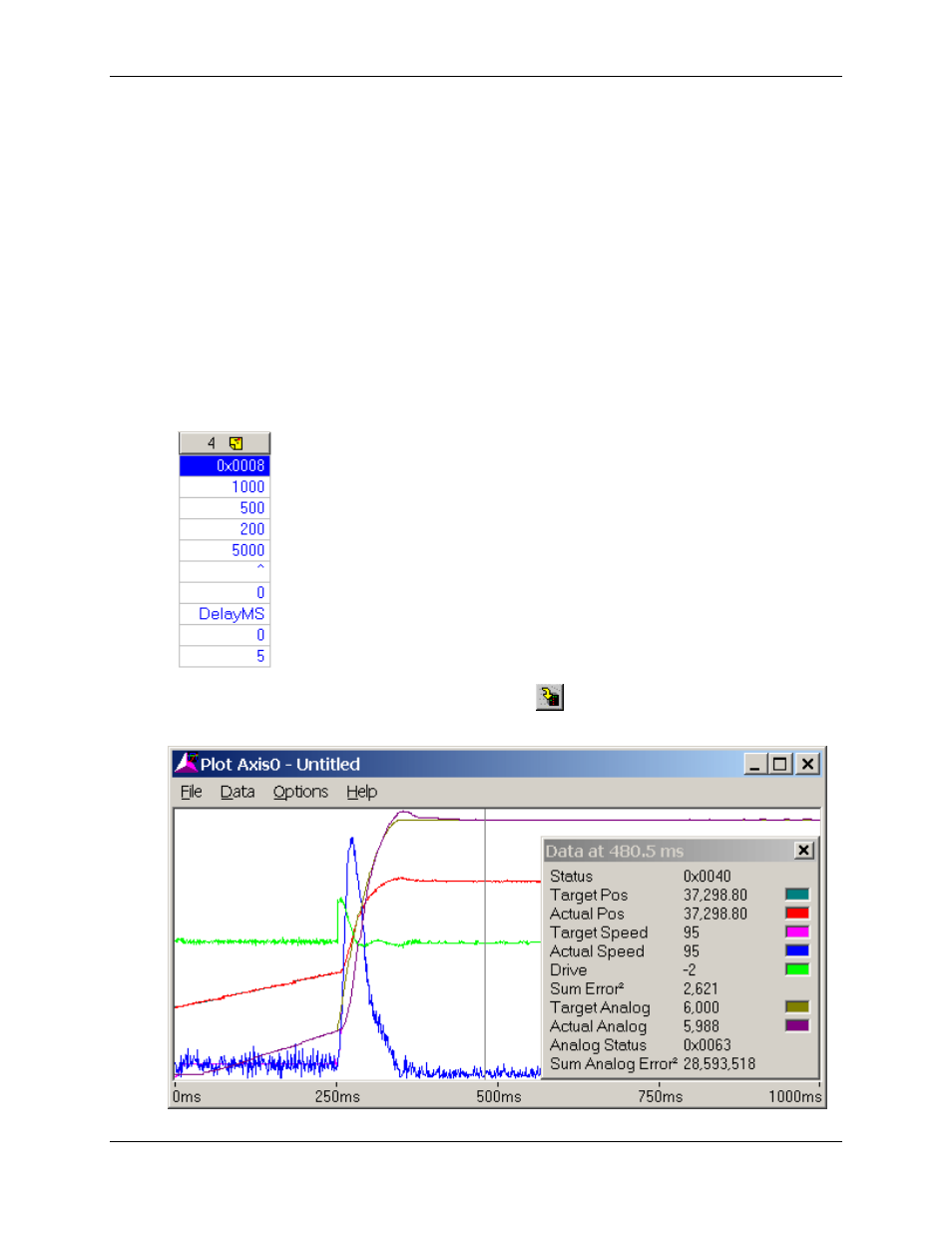

• To try the "Set ramp time" option, double-click the Mode word of Event Step 4 and in the Ramp

Time

field click Use ramp time value. Click OK. Set the ramp time to 200 (in the Speed field).

Step 4 now looks like this:

• Download the Step table to the RMC by clicking the

button in the Event Steps window. Run

Event Step 1. The plot looks like this: