Delta RMC101 User Manual

Page 598

RMC100 and RMCWin User Manual

6-54

between the Target Position and the outgoing steps.

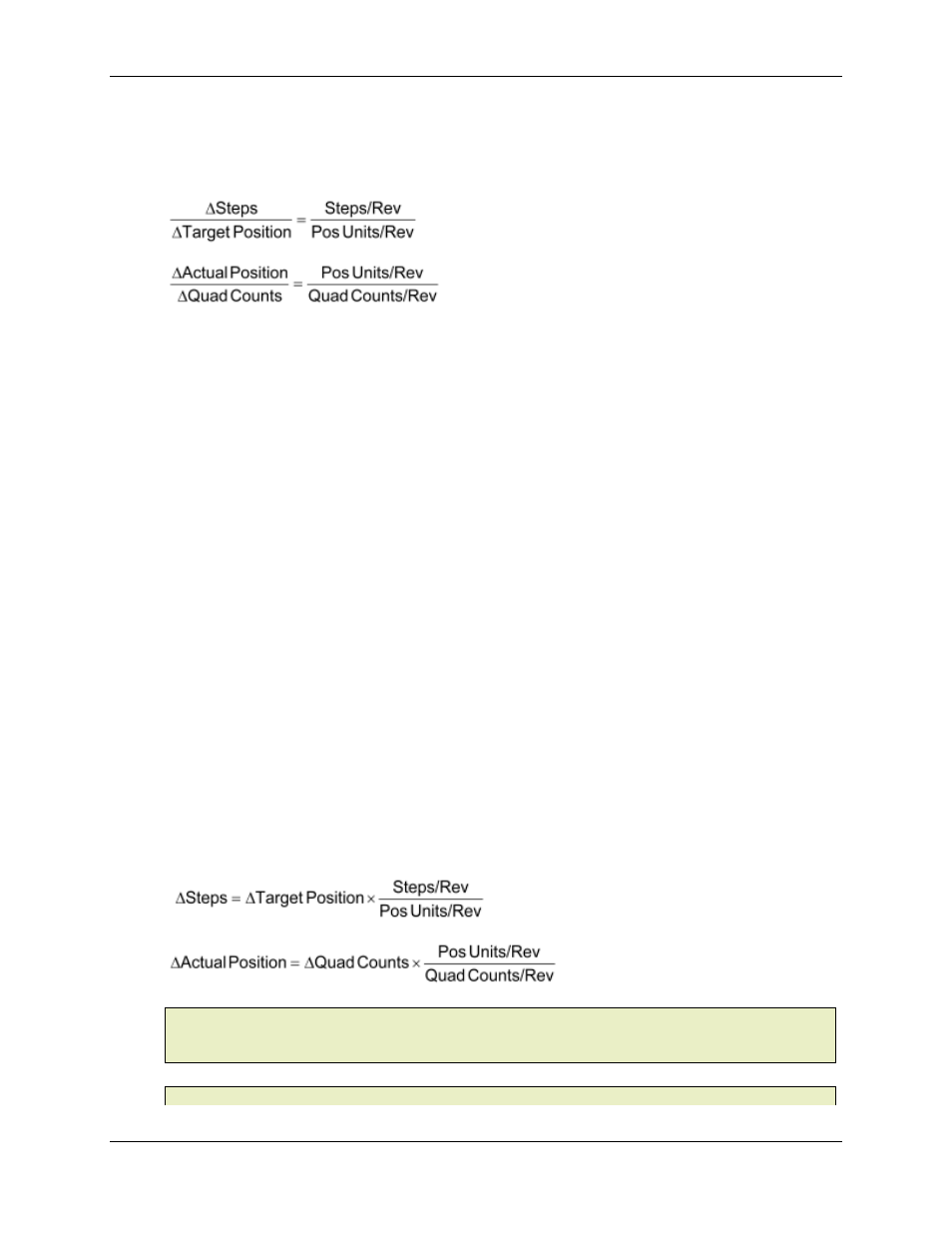

Each scale is defined as a ratio of two numbers. The user can enter both numbers in each of the

ratios, although one number is shared by both ratios. Here is the definition of the two scales:

The three values the user can enter are Steps/Rev, Pos Units/Rev, and Quad Cnts/Rev. These

are parameters for each stepper axis. You will notice that both scales use Pos Uints/Rev.

The RMC allows the user to select the direction of both the stepper and quadrature counts with

respect to position units. That is, phase A leading phase B in the quadrature can mean increasing

or decreasing actual positions. Similarly, a low direction line can be the result of increasing or

decreasing target positions.

The sign of the Quad Counts/Rev parameter controls the quadrature direction per the following

chart:

Quad Counts/Rev

The actual position increases when…

+

…phase A leads phase B

-

…phase B leads phase A

The Reverse Drive bit of the Configuration Word controls the use of the direction output to the

stepper motor per the following chart:

When the target positions…

Reverse Drive bit

…increase…

…decrease…

0

…Direction will be low.

…Direction will be

high.

1

…Direction will be

high.

…Direction will be low.

These scales are used to determine the change in steps from the change in target position and to

determine the change in actual position from the change in quadrature counts according to the

following formulas:

Note:

The RMC ensures that no fractional position units or steps are lost in these conversions.

That is, even though the result of this equation will likely not be a whole number, the remainder

is carried from scan to scan.

Note:

If quadrature feedback is not used, enter a 0 in QUAD CNTS/REV. This eliminates the