Delta RMC101 User Manual

Page 782

RMC100 and RMCWin User Manual

C-12

TIP:

After the axis has made a complete move without oscillations or overdrive errors, use the 'F'

command to automatically set the Feed Forward value.

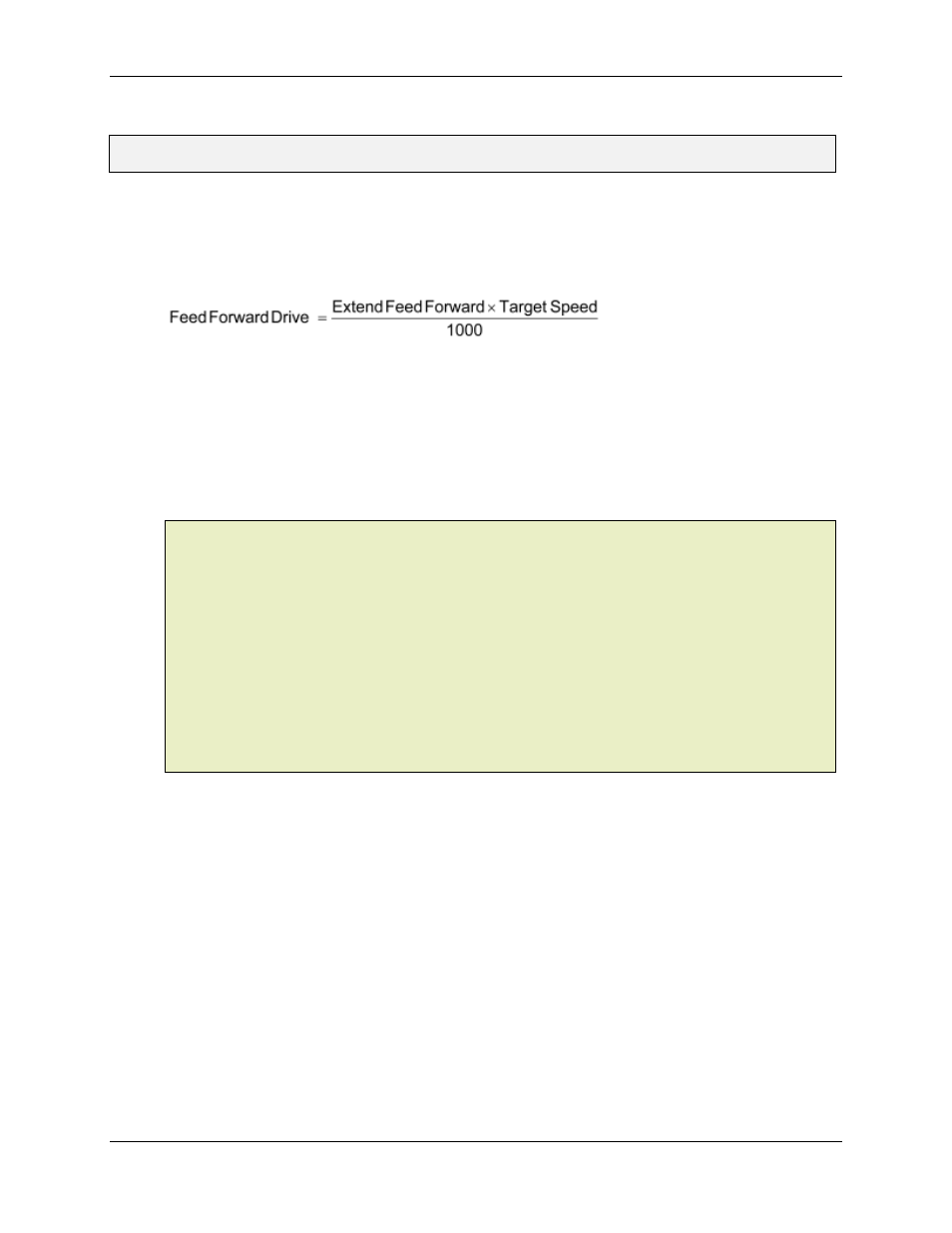

Feed Forward is an open loop compensation that is proportional to the Target Speed of the axis.

This value is expressed in terms of millivolts per 1,000 Position Units per second. Extend Feed

Forward drive is added to the output only when the axis is extending. The drive output provided

by the Extend Feed Forward is determined as follows:

You can find the appropriate value for Extend Feed forward by making a move with the axis using

a Speed of 1,000. The amount of output drive required to maintain this speed should be used as

the Extend Feed Forward parameter. If the axis lags after the parameter has been set, the feed

forward is too small or the system response is too slow. If the axis leads, the feed forward is too

large or the system response is too slow. The 'F' command used after an extend move will

automatically adjust the Extend Feed Forward parameter. The Extend and Retract Feed

Forwards are also known as velocity feed forwards.

Note:

Feed Forward Drive is limited to a maximum value of 10,000. Inserting that value in the equation

above and solving for the Feed Forward term gives the follow relationship:

Feed Forward <= (10,000 * 1,000) / Target speed

That is, the larger the Speed the smaller the maximum Feed Forward value.

For example, at 30 in/sec Speed, the maximum Feed Forward is:

Max Feed Forward = (10,000 * 1,000)/30,000 = 10,000/30 = 333

If you set Speed to 30,000 and enter a Feed Forward value larger than 333, the value will be

reduced to 333.

Think about this:

If the feed forward value is less than 300, an axis going at a speed of 65535 will not get a full

valve drive from the feed forward term alone. If the feed forward value is less than 200, the axis

drive system is too big and the system may have trouble controlling position. If this happens, then

reduce the gain on the amplifier or use a smaller valve or reduce pressure until the feed forward

terms are over 300.

On hydraulic systems, the extend and retract feed forward terms will be different by the ratio of

the extend and retract surface areas of the position.

The Proportional Gain, Integral Gain and Differential Gain as well as the Integral Drive Limit are

adjusted internally based on the ratio of the Extend and Retract Feed Forwards. The direction

with the lower Feed Forward value will have effectively lower Gains and Integral Limit. This is

done to compensate for the different system dynamics in the two directions.

For example, for a system with an Extend Feed forward of 100 and a Retract Feed Forward of

200 the effective gains in the extend direction will be one half (100 / 200) as big as the specified