Delta RMC101 User Manual

Page 287

Digital I/O 5.1

Communications

5-37

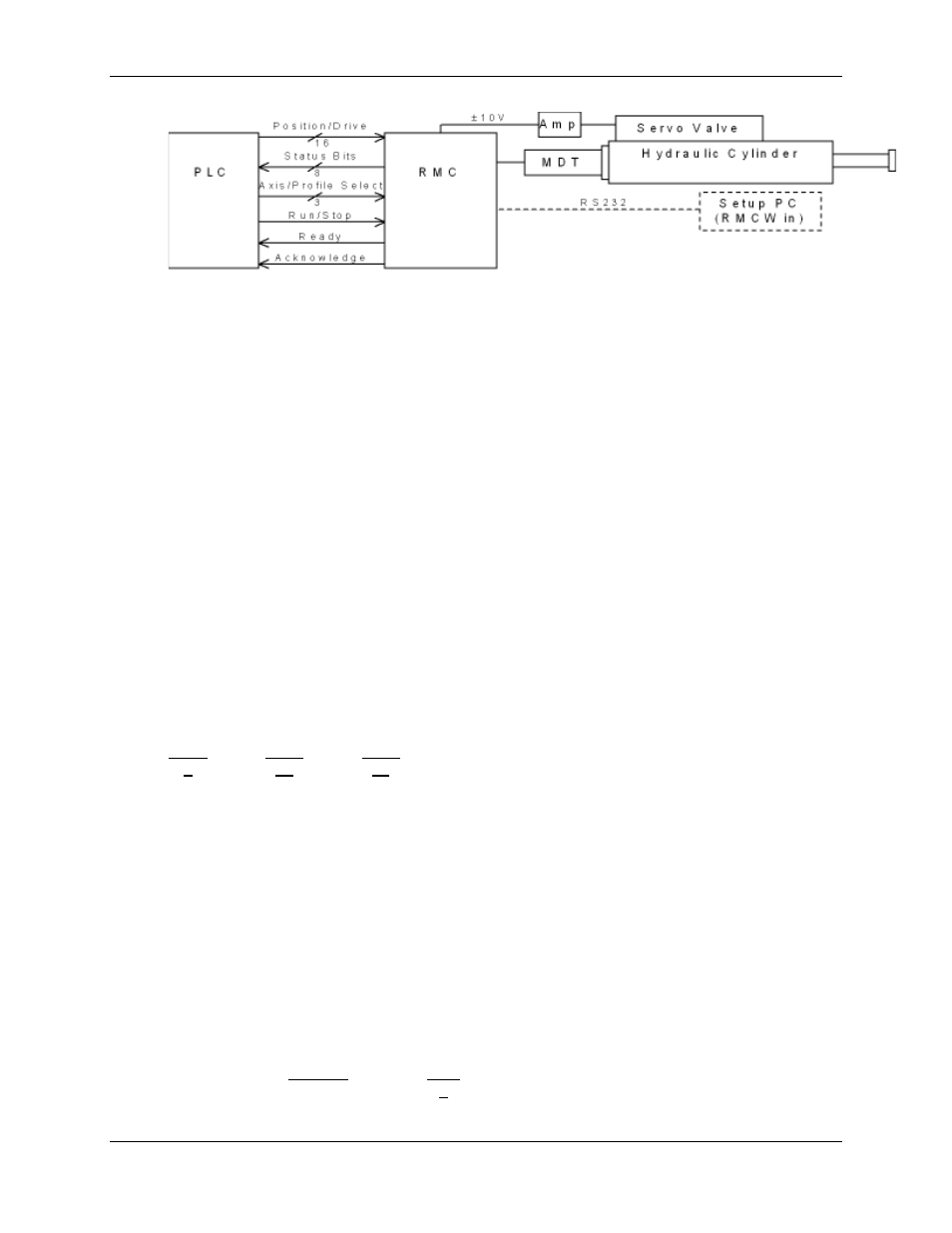

This document discusses only the connections between the Programmable Controller and the

RMC. For details on the transducer and drive wiring, look up Wiring Notes in the RMCWin index.

The following points describe the operation of Parallel Position mode:

• Parameters and tables used by the RMC are configured using the RMCWin software and stored

in the RMC Flash memory.

• All axes are initialized by raising the Run/Stop (CPU input 0) line on the RMC, and all axes are

immediately stopped by the falling of the Run/Stop line on the RMC. Therefore, an emergency-

stop button often controls the Run/Stop input.

• The Ready (CPU output 0) line matches the Run/Stop input line to give feedback to the

controlling system that the RMC is ready to take commands.

• When the Run/Stop line is set, the Position/Drive or Axis/Profile Select (described below) lines

are monitored for changes. When any of these inputs change, and they remain stable for a user-

configured duration (between 2 and 20 milliseconds), a new command is issued to the RMC.

• The Axis/Profile Select (CPU input 1 and DI/O inputs 16-17) lines select both the profile of the

new command, and the axis the command is sent to.

The profile is selected from one of the first eight profile entries in the RMCs Profile table. The

following chart indicates how the inputs are used to select the profile:

CPU

DI/O

Input

1

Input

17

Input

16

0

0

0

0

0

1

0

1

0

0

1

1

1

0

0

1

0

1

1

1

0

1

1

1

The bits used to select the axis that receives the command change depending on the total number

of axes in the module. The following charts indicate how the inputs are used to select the axis:

Two axes:

DI/O

Input 16

Axis

#

0

0