5motor control (mctrl) – Lenze 8400 TopLine User Manual

Page 288

5

Motor control (MCTRL)

5.12

Braking operation/brake energy management

288

Lenze · 8400 TopLine · Reference manual · DMS 6.0 EN · 06/2014 · TD05/TD14

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

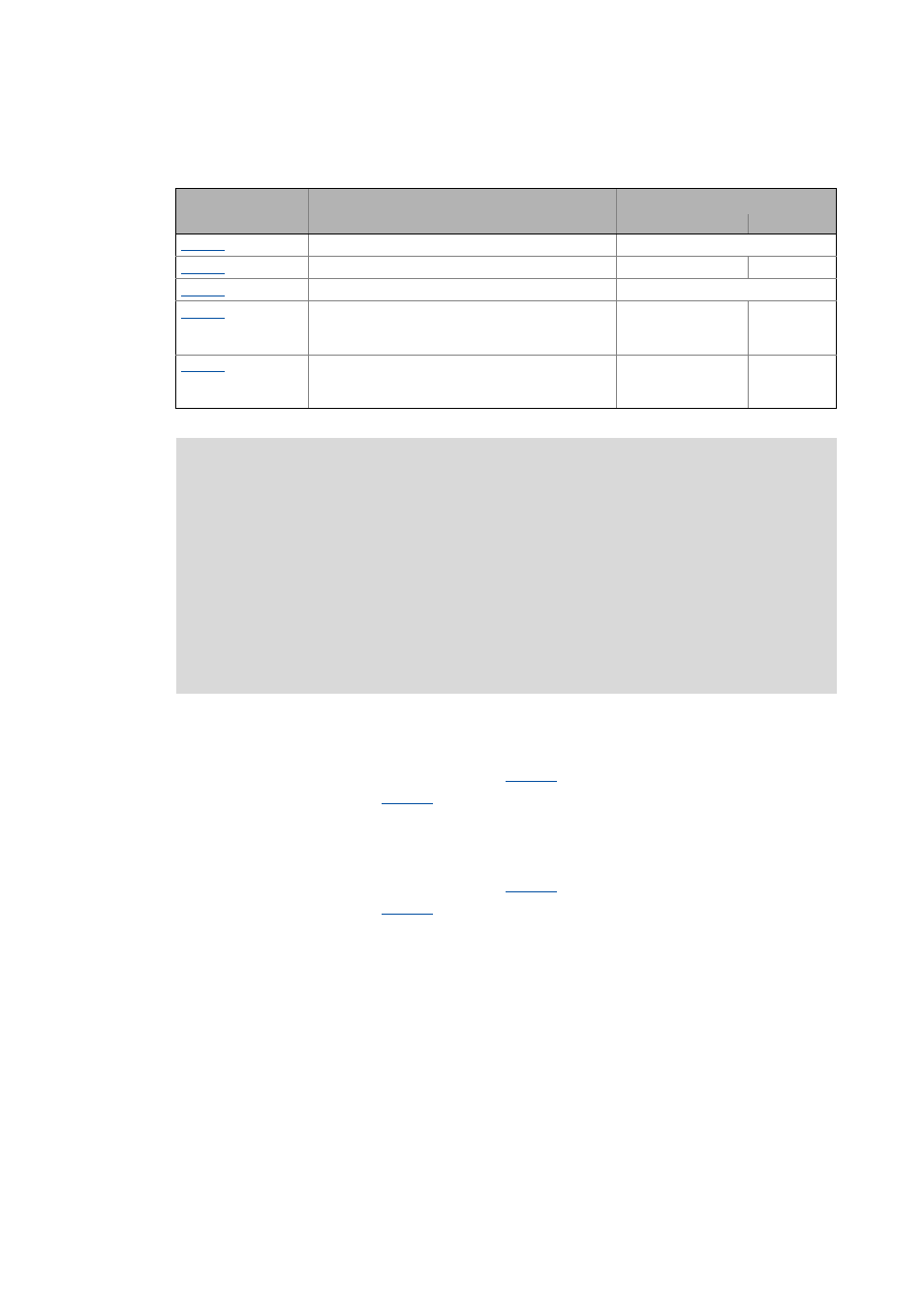

Short overview of the relevant parameters:

How to set the "inverter motor brake" function for an oscillation-reduced operation:

For V/f characteristic open-loop control/closed-loop control (VFCplus):

• Set reduced brake chopper threshold (

) to approx. 70 V.

• Set additive speed (

) to rated slip speed.

• Adapt the deceleration ramp so that the deceleration time is slightly below (10 ... 30 %)

the deceleration time that can be realised with the inverter motor brake.

For sensorless vector control (SLVC) and servo control (SC):

• Set reduced brake chopper threshold (

) to approx. 50 V.

• Set additive speed (

) to 1 ... 2-fold rated slip speed.

• Adapt the deceleration ramp so that the deceleration time is slightly below (10 ... 30 %)

the deceleration time that can be realised with the inverter motor brake.

Parameter

Info

Lenze setting

Value Unit

Mains voltage

3ph 400V / 1ph 230V

Reduc. brake chopper threshold

0 V

Resp. to brake resistor control

Brake resistor

Inverter motor brake: nAdd

• Speed lift which is connected in pulses to the

brake rampe when the motor is braked.

80 rpm

Inverter motor brake: PT1 filter time

• PT1 filter time for smoothing the speed lift which

is added in pulses.

0.0 ms

Note!

When the "inverter motor brake" function is used, torque oscillations occur which have

may have a negative effect on the service life of the components of the mechanical drive

train (e.g. gearbox).

• The extent of the occurring oscillations depends on the drive train (mass inertia,

natural frequencies, etc.) and the function setting.

• We recommend optimising the "inverter motor brake" function for an oscillation-free

operation as described in the following. Usually, this setting does not cause any

torque oscillations which affect the service life of the gearbox.

• The settings of implementing a maximum acceleration ramp are only recommended

if the inverter motor brake is used infrequently (e.g. in case of quick stop).