5 remedies for undesired drive behaviour, Remedies for undesired drive behaviour, 5motor control (mctrl) – Lenze 8400 TopLine User Manual

Page 184

5

Motor control (MCTRL)

5.5

V/f characteristic control - energy-saving (VFCplusEco)

184

Lenze · 8400 TopLine · Reference manual · DMS 6.0 EN · 06/2014 · TD05/TD14

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.5.5

Remedies for undesired drive behaviour

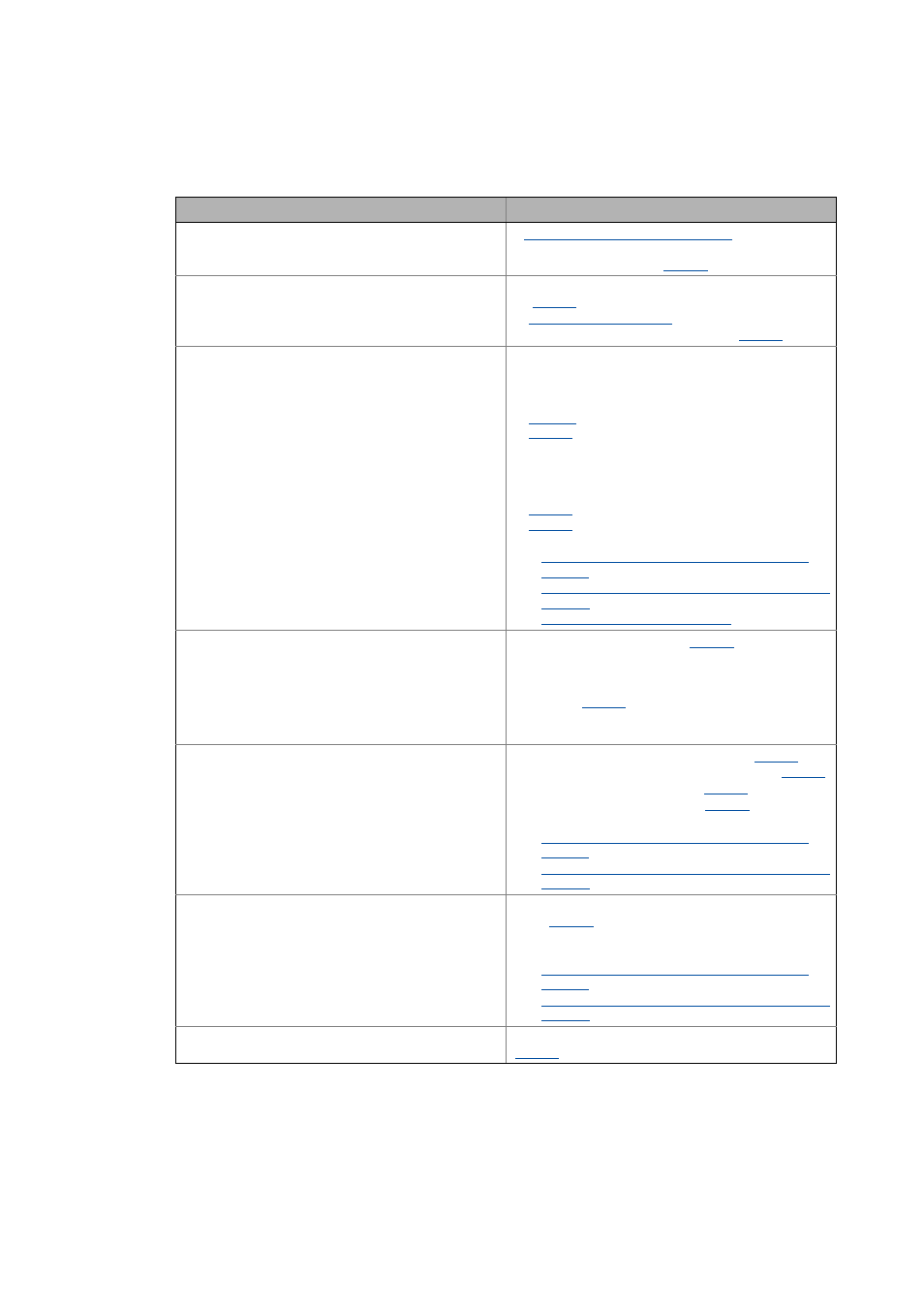

Drive behaviour

Remedy

Inadequate smooth running at low speeds, especially in

the case of operation with a long motor cable

Automatic motor data identification ( 141)

Reduce the influence of the Eco function by increasing

the minimum voltage V/f (

) if necessary.

Problems in case of high starting duty (great mass

inertia)

1.Set motor control VFCplus with linear characteristic

(

= 6).

2.

3.Again set motor control VFCplusEco (

= 11).

Drive does not follow the speed setpoint

The current controller intervenes in the set field

frequency to limit the controller output current to the

maximum current (C0022, C0023). Therefore:

• Prolong acceleration/deceleration times:

Accel. time - main setpoint

: Decel. time - main setpoint

• Consider a sufficient magnetising time of the motor.

Depending on the motor power, the magnetising

time amounts to 0.1 ... 0.2 s.

• Increase the maximally permissible current:

: Imax in motor mode

: Imax in generator mode

• Make adaptations for the Eco function:

•

Improving the behaviour at high dynamic load

•

Adapting the slope limitation for lowering the Eco

.

•

Optimising the cos/phi controller

Insufficient speed constancy at high load (setpoint and

motor speed are not proportional anymore)

• Increase slip compensation (

Important: Unstable drive due to overcompensation!

• With cyclic load impulses (e. g. centrifugal pump), a

smooth motor characteristic is achieved by smaller

values in

(possibly negative values).

Note: The slip compensation is only active for operation

without speed feedback.

"Clamp operation active" error message (oC11):

Controller cannot follow dynamic processes, i.e. too

short acceleration/deceleration times in terms of load

ratios.

• Increase the gain of the I

max

controller (

)

• Reduce the reset time of the I

max

controller (

)

• Prolong the acceleration time (

)

• Prolong the deceleration time (

• Make adaptations for the Eco function:

•

Improving the behaviour at high dynamic load

•

Adapting the slope limitation for lowering the Eco

.

Motor stalling in the field weakening range

(adaptation especially required for small machines)

• If motor power < inverter power:

max

= 2 I

rated motor

• Reduce dynamic performance of setpoint generation

• Make adaptations for the Eco function:

•

Improving the behaviour at high dynamic load

•

Adapting the slope limitation for lowering the Eco

.

Speed variations in no-load operation for speeds > 1/3

rated speed.

Minimise speed oscillations with oscillation damping

(

).