19 function library, Stop – Lenze 8400 TopLine User Manual

Page 1505

Lenze · 8400 TopLine · Reference manual · DMS 6.0 EN · 06/2014 · TD05/TD14

1505

19

Function library

19.1

Function blocks

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Angular trimming

Angular trimming enables the rotor position to be put forward or back with regard to the setpoint

(the drive is leading or lagging).

The correction value must has to be defined in [increments] via the nPositionTrimming input. It is

internally added to the angle setpoint.

• Scaling: A motor revolution is mapped with 65536 increments or steps.

• The maximum angular trimming amounts to ±½ motor revolution (±32767 increments).

• When analog values are selected: 100 % ≡ ¼ motor revolution ≡ 16384 increments.

• The setting range can be extended with the multiplier to be set in

Angular offset

The dnPosOffset_p input serves to define a permanent angular offset for the setpoint of the drive.

• An adjustment takes place via the following error (dnDeltaPos_p) output and via the speed

change at the nSpeedSetOut_v output.

• Example: A angular offset of 90° is to be set on the load side with a gearbox ratio of 3.8147:

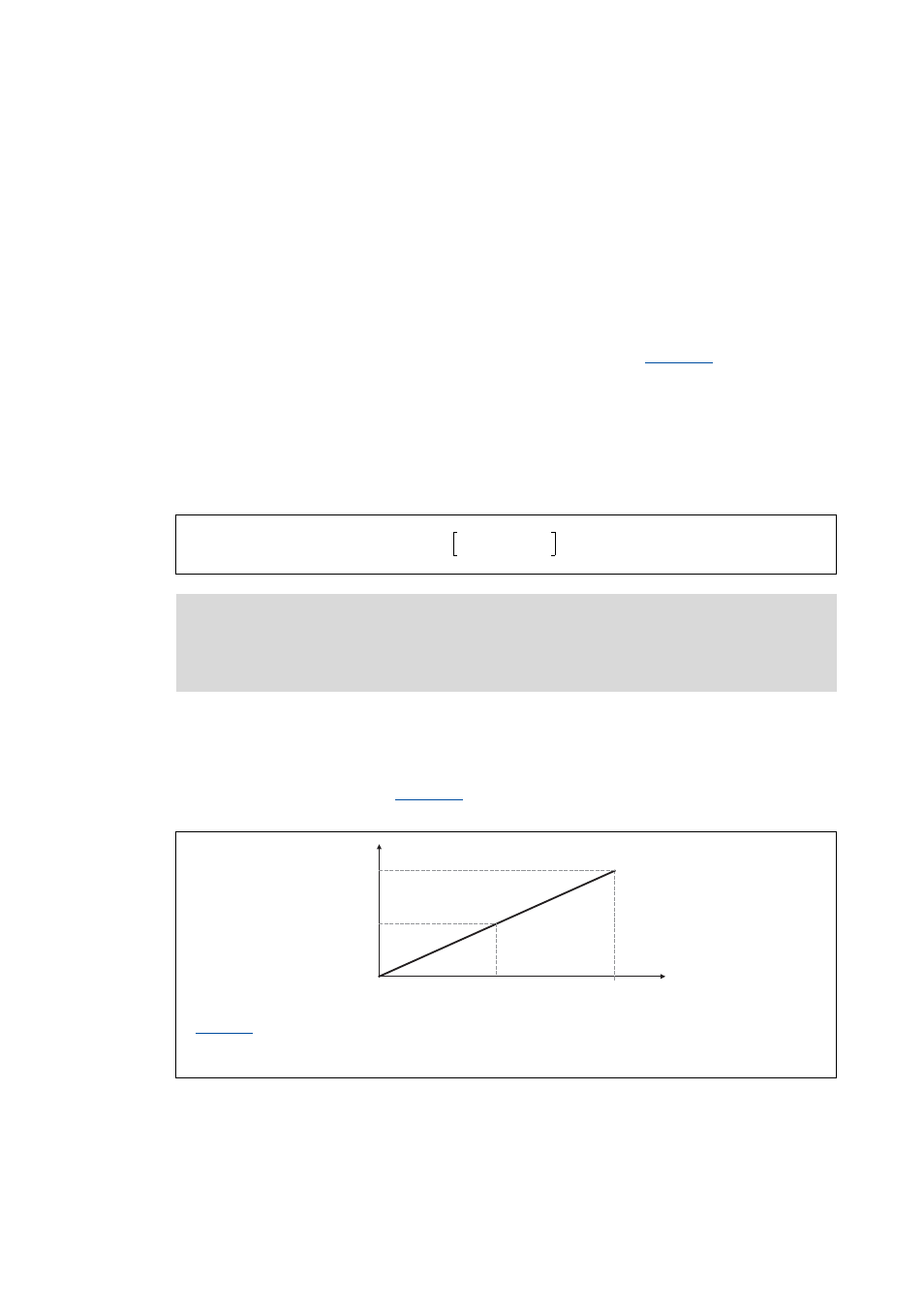

Speed-proportional angle adjustment

The speed-proportional angle adjustment enables a leading or lagging of the angle with increasing

speed and serves to compensate dead times and transmission times.

The correction value selected in

. in [increments] refers to a speed of 15000 rpm (linear

relationship):

[19-36] Connection between offset/speed

Stop!

Change the angular offset only step by step as the FB does not contain a ram generator

for preventing torque impulses.

: Speed-proportional angle adjustment

Effective offset

Current speed

dnPosOffset_p

90°

360°

------------

65536

Increments

Motor revolution

--------------------------------------------

3.8147

⋅

⋅

62500 [increments]

=

=

Offset

v

16384 inc/ms

(15000 rpm)

0

1