5 remedies for undesired drive behaviour, Remedies for undesired drive behaviour, 5motor control (mctrl) – Lenze 8400 TopLine User Manual

Page 208

5

Motor control (MCTRL)

5.7

Sensorless vector control (SLVC)

208

Lenze · 8400 TopLine · Reference manual · DMS 6.0 EN · 06/2014 · TD05/TD14

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.7.5

Remedies for undesired drive behaviour

Drive behaviour

Remedy

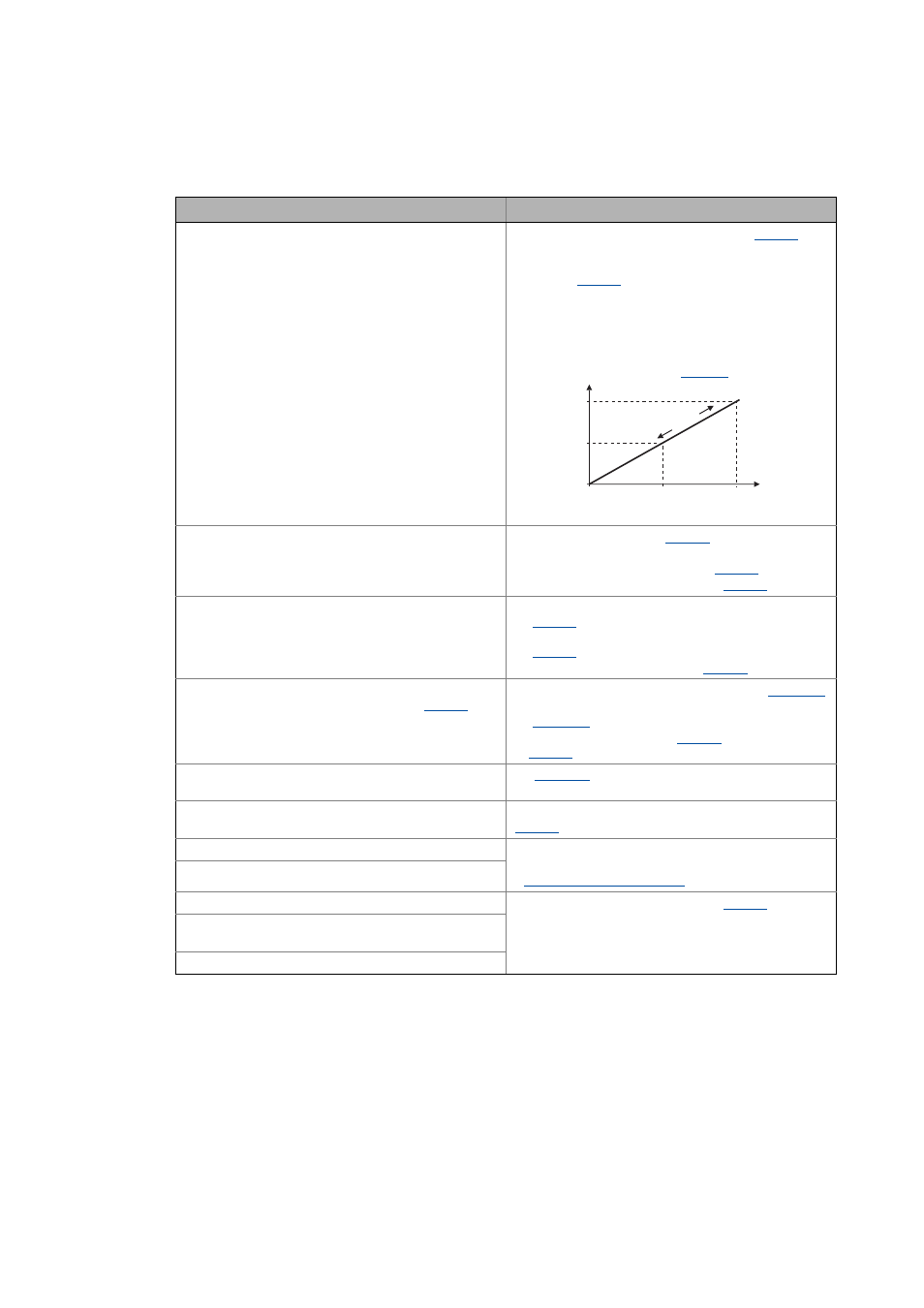

Deviation between no-load current and magnetising

current or bad speed or torque accuracy.

Adapt the motor magnetising inductance (

) for

no-load operation.

• If the no-load current is greater than the magnetising

current (

) at 0.5-fold rated motor speed, the

magnetising inductance must be reduced until the

no-load current and the magnetising current have the

same values.

• Otherwise, the magnetising inductance must be

increased.

Tendency of the correction of

PN: Rated motor power

Insufficient speed constancy at high load: Setpoint and

motor speed are not proportional anymore.

Caution: Overcompensation of the settings mentioned

under " Remedy" may result in unstable behaviour!

Via the slip compensation (

), the speed stability

under high loads can be affected:

• If n

act

> n

slip

, reduce the value in

• If n

act

< n

slip

, increase the value in

Unstable control with higher speeds.

• Check the setting of the magnetising inductance

(

) by comparing the current consumption in

no-load operation with the rated magnetising current

(

).

• Optimise oscillation damping (

"Short circuit" (oC1) or "Clamp operation active" (oC11)

error messages at short acceleration time (

) in

proportion to the load (controller cannot follow the

dynamic processes).

• Increase the gain of the torque controller (

• Reduce the reset time of the torque controller

(

• Increase the acceleration (

)/deceleration (

) time.

Mechanical resonance at certain speeds.

function block masks out those speed

ranges that include resonance.

Speed variations in no-load operation for speeds > 1/3

rated speed.

Minimise speed oscillations with oscillation damping

(

).

Drive runs unstable.

Check set motor data (nameplate data and equivalent

circuit diagram data).

Motor selection/Motor data ( 135)

Setpoint speed and actual speed differ strongly.

The torque required is not generated at standstill.

Increase motor magnetising current (

).

Current overshoots occur when heavy loads are

accelerated from standstill (OC1 or OC11 error).

The machine runs uneven.

0,37

22

90

C0092

-15 %

+15 %

0

P [kW]

N