1 typical application, 5function blocks – Lenze E94A User Manual

Page 463

Lenze · 9400 function library · Reference manual · DMS 6.7 EN · 08/2014 · TD05

463

5

Function blocks

5.124

L_SdIntegrateAxis - speed to position integration (with TP correction)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.124.1

Typical application

Mark-controlled start of a following axis

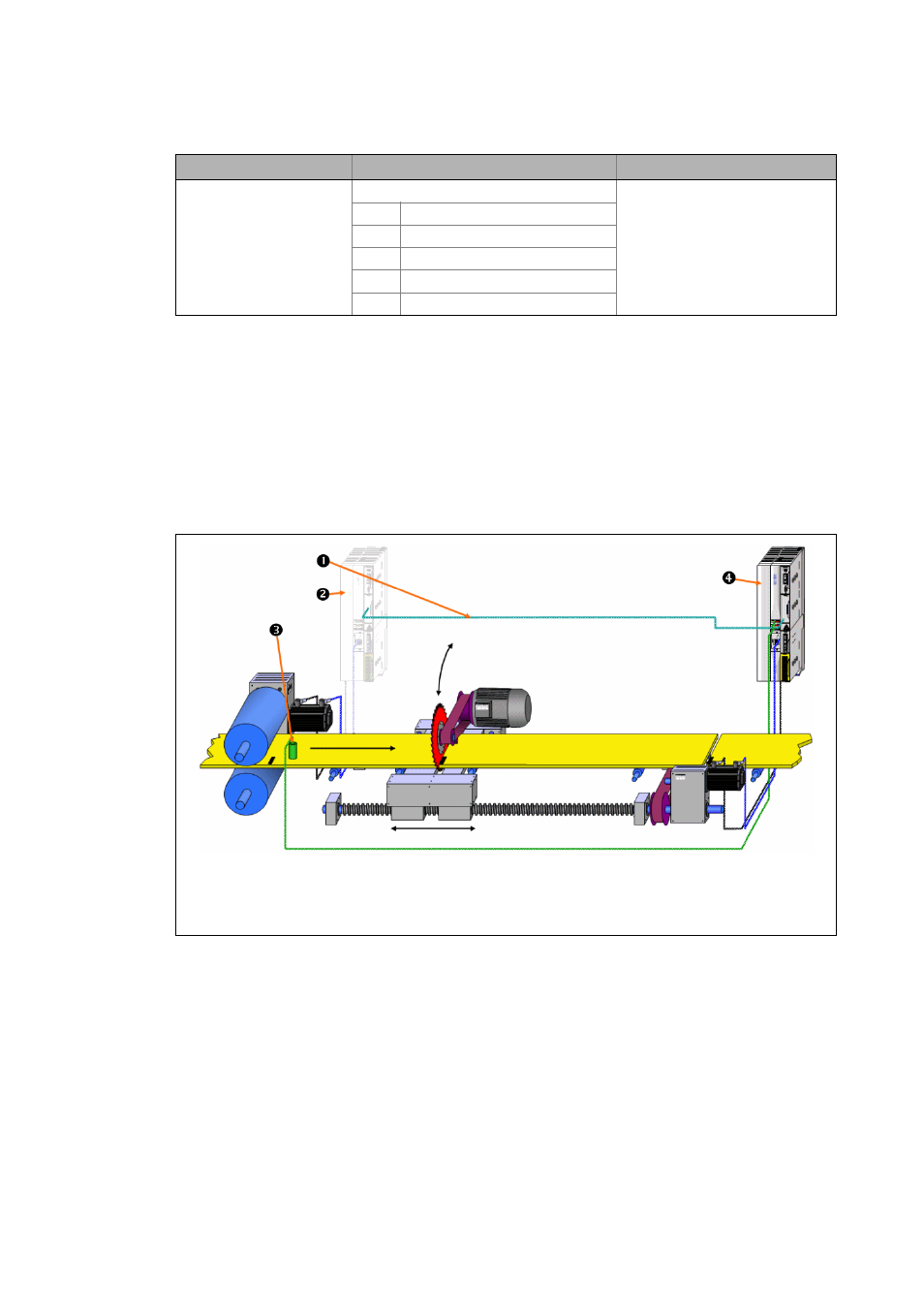

The following illustration shows the "flying saw" application. If no mark has been detected, the sla-

ve drive remains in its waiting position. Even if the material is fed, no material motion is shown via

the position output of the FB, as no mark signal has been detected. Only if a mark has been detected

via the touch probe sensor, the internal integrator starts and maps the material feed.

[5-74] Example: flying saw

Measuring integrator for master position

In many cases integrators are not only required for motion control, but simply for generating com-

parison measuring systems (e. g. master cycle generation without direct influence on the drive mo-

tion).

The FB makes it possible to set the positions once, or even cyclically in a "hard" manner, via touch

probe signals, which is desired in such cases.

C04359

Bit coded:

Status

• Bits that are not itemised are re-

served for future extensions.

bits10 Zero crossing active

bit16 Position is beyond the cycle

bits17 Initial speed too high

bits23 Invalid axis data structure

bits31 General error

Parameter

Possible settings

Information

Digital frequency connection

Master drive (material feed)

Touch probe sensor for mark-controlled start

Slave drive (flying saw)