1 typical application, 5function blocks – Lenze E94A User Manual

Page 330

5

Function blocks

5.91

L_LdMarkSync - mark synchronisation

330

Lenze · 9400 function library · Reference manual · DMS 6.7 EN · 08/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.91.1

Typical application

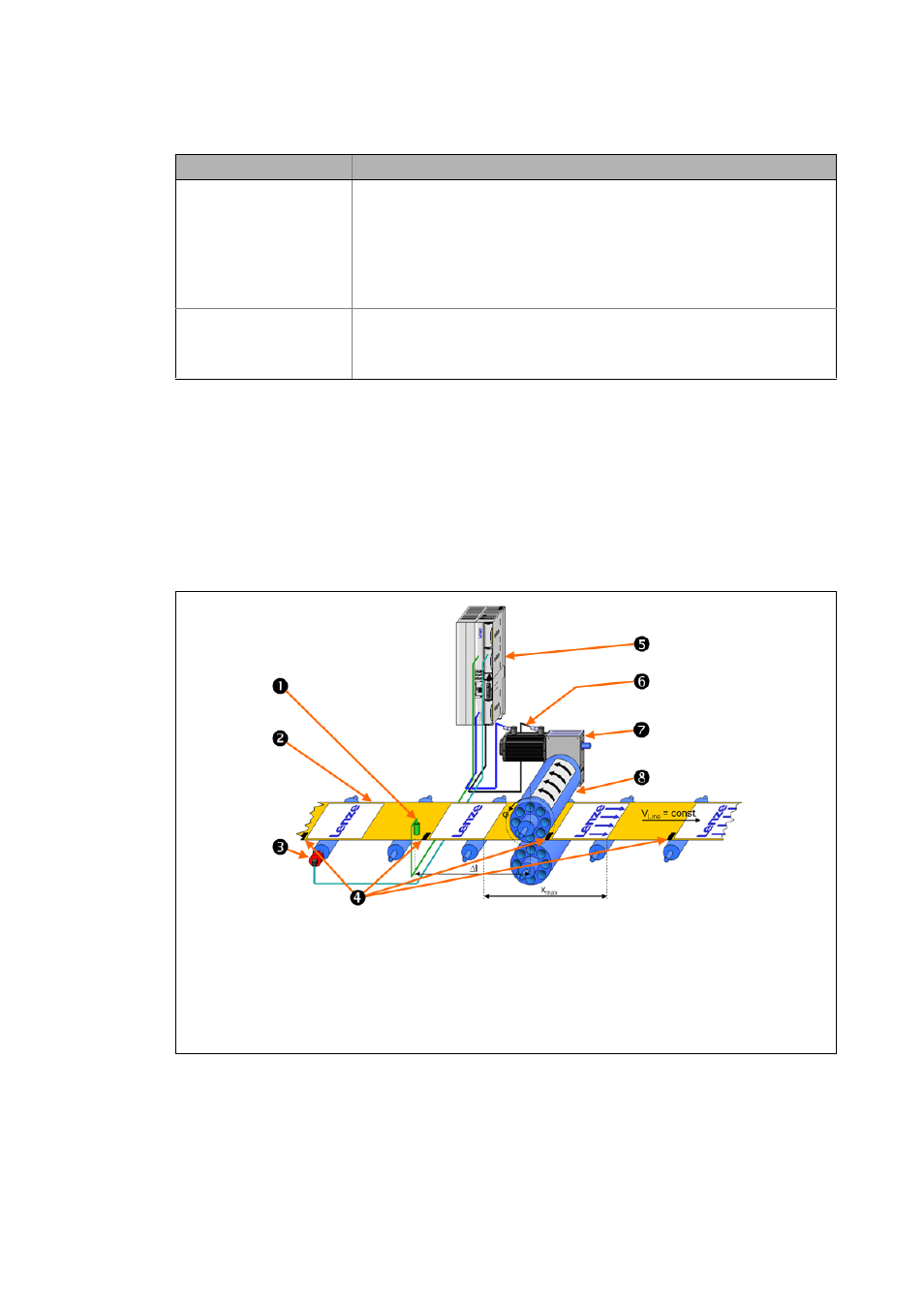

Many synchronous operations require a slave drive (tool) to move in synchronism with a master si-

gnal/master drive. This motion can be corrected using additional sensor technology.

In the following example, a print register has already been defined by print marks on the web. High-

precision detection of these print marks in the controller is possible via fast digital inputs (touch pro-

be inputs).

[5-48] Example: Printing roller drive including print-mark correction

dnTpTpDistance_p

DINT

Distance between the two touch probes last detected in [increments]

• May e.g. serve to determine the print register (distance between two print

marks).

• Please make sure that the touch probe sensor is positioned in such a way that no

cycle without touch probe detection is possible between two detected touch pro-

bes. In this case, the output would indicate a distance which is one cycle too short.

This can be prevented by positioning the touch probe sensor in the middle of the

cycle.

dnTpPos_p

DINT

Detected TP position in [inc]

(Actual TP position at which the current touch probe has been detected.)

• The distance to the TP setpoint position is calculated using the actual TP position

that is output here: dnTpDifference_p = dnTpSetPos_p - dnTpPos_p

Identifier/data type

Value/meaning

Print-mark sensor

Web including print register 0 ... x

max

(print image: "Lenze")

Master value encoder

Print marks

9400 controller (slave drive = printing roller)

Printing roller drive motor including feedback system

Gearbox (slave drive)

Printing roller including block (print image: "Arrows")