5function blocks – Lenze E94A User Manual

Page 329

Lenze · 9400 function library · Reference manual · DMS 6.7 EN · 08/2014 · TD05

329

5

Function blocks

5.91

L_LdMarkSync - mark synchronisation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

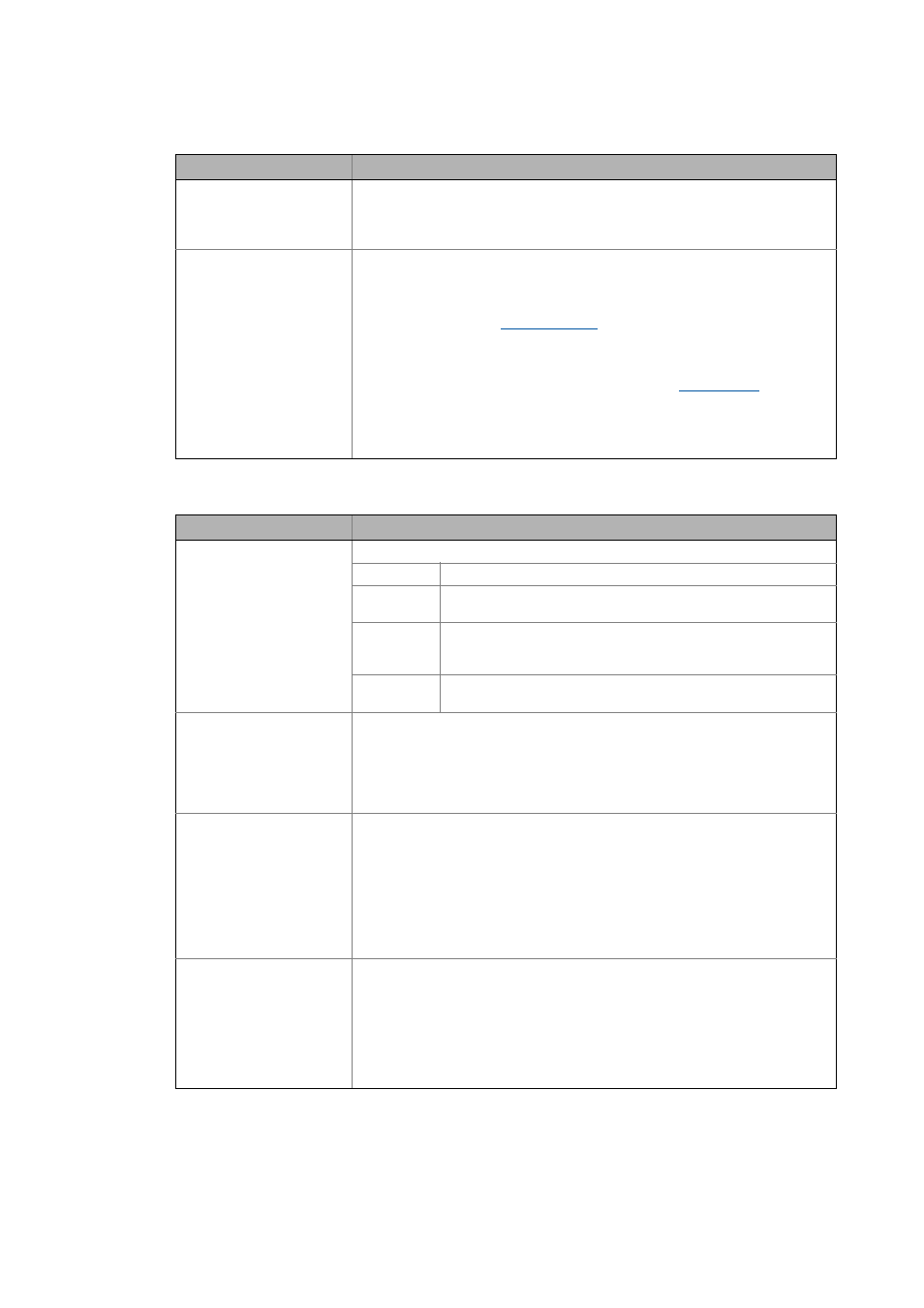

Outputs

dnTpSetPos_p

DINT

Touch probe setpoint position in [inc]

• At this input, specify the position at which the touch probe ideally occurs.

• If the touch probe is detected at its (ideal) TP setpoint position, a correcting mo-

tion is not required (TP difference dnTpDifference_p = 0).

AxisData

Specification of the measuring system which is used to evaluate the touch probe

event.

The following sources can be used for this input:

• If the master position is corrected (x touch probe), an arbitrary measuring system

can be defined via the

FB. In this case, its AxisData output must

be connected to this input.

• If an axis position is corrected (y touch probe), the DI_AxisData output of the

LS_DriveInterface SB must be connected to this input.

• Some of the cam technology function blocks (e.g. the

FB) output

the measuring systems defined via »Cam Designer«. In this case, the correspon-

ding measuring system output must be connected to this input.

Note:

The connected measuring system must be a modulo measuring system.

Identifier/data type

Value/meaning

dnState

DINT

Status

Bit15 Group error (see bit 16 ... 31)

bits18 The specified modulo measuring system (the AxisData input) does

not have a valid cycle (cycle = 0).

bits20 The TP setpoint position at the dnTpSetPos_p input is outside of the

permissible cycle of the modulo measuring system (the AxisData in-

put).

bits23 Error in the measuring system: The pointer at the AxisData input

does not refer to a valid axis data structure.

dnPosOffset_p

DINT

Aggregated position offset in [increments]

(Aggregation of all correcting motions performed so far)

• This output outputs an unlimited correction position.

• If the TP is corrected at the axis side (y touch probe), the output can directly be

connected to the FDB_dnPosOffset_p input of the LS_Feedback SB when the axis

needs to be corrected.

dnActDifference_p

DINT

Remaining position difference in [increments]

• If a touch probe is detected via the bTpReceived input, this output is set to the de-

tected TP deviation, dnTpDifference_p.

• Then, the remaining TP deviation is compensated to zero via the

dnMakeUpLeeway_s input if a correcting motion is reported (correction distance

monitoring).

• The shorter distance to the TP setpoint position is always output.

(Caution: The function block requires a modulo measuring system to work cor-

rectly!)

dnTpDifference_p

DINT

Last TP deviation in [inc]

(TP deviation between the TP setpoint position, dnTpSetPos_p, and the actual positi-

on, dnTpPos_p, at which the touch probe has been detected.)

• If a touch probe is detected via the bTpReceived input, the dnActDifference_p out-

put is set to this value additionally.

• The shorter distance to the TP setpoint position is always output.

(Caution: The function block requires a modulo measuring system to work cor-

rectly!)

Identifier/data type

Information/possible settings