L_camsyncin, 5function blocks – Lenze E94A User Manual

Page 186

5

Function blocks

5.11

L_CamSyncIn - synchronous/oversynchronous clutch-in

186

Lenze · 9400 function library · Reference manual · DMS 6.7 EN · 08/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.11

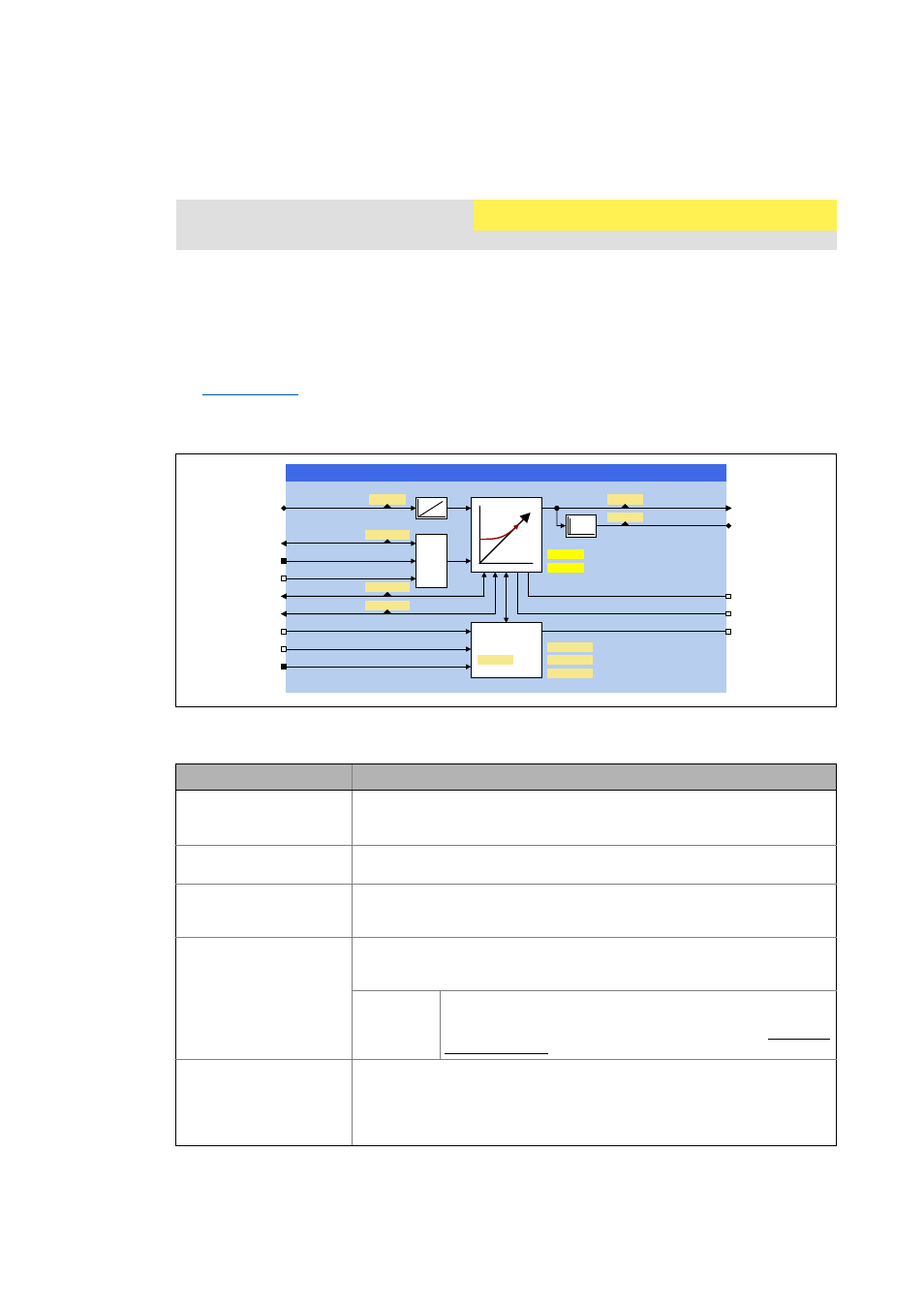

L_CamSyncIn - synchronous/oversynchronous clutch-in

This FB serves to synchronise a tool (drive) to a running material (relative master speed).

• Types of synchronisation:

• Mark-controlled (touch probe)

• Manually controlled (e.g. manually controlled top cut with flying saw)

• The synchronisation is path-based and functionally corresponds to a subset of the

clutch module. Synchronous or oversynchronous synchronisations are possible.

• The function corresponds to the "DFRFG" function of the 9300EK servo inverter and additionally

supports a path-controlled clutch-in.

Inputs

Function library:

LenzeCam

FB is available as of library V01.01.xx.xx!

FB may only be used for firmware as of V3.0!

Runtime software licence:

Motion Control HighLevel

Motion Control TopLevel

Identifier/data type

Information/possible settings

dnSpeedIn_s

DINT

Input speed (master speed) as speed in [rpm]

• Example: Material speed of the web with flying saw.

• C05605 indicates the input speed in the real unit of the machine.

dnTpPos_p

DINT

Position of the touch probe sensor in [increments].

• C05606/1 indicates the position in the real unit of the machine.

dnTpTimeLag

DINT

Input for accepting the time stamp

• Connect this input with the output dnTouchProbeTimeLag of the corresponding

touch probe system block.

bTpReceived

BOOL

Input for taking over the status "Touch probe detected"

• Connect this input with the output dnTouchProbeReceived of the corresponding

touch probe system block.

FALSETRUE Touch probe detected.

Note: At the same time, a speed must be applied at the dnSpeedIn_s

input for the clutch-in ramp to be calculated. Otherwise, the clutch-

in process will not be started in the FB.

dnOpenPos_p

DINT

Clutch-in position in [increments]

• Starting position for synchronising.

• Is generally also used as target position for the LS_Positioner system block for re-

positioning.

• C05606/2 indicates the clutch-in position in the real unit of the machine.

GQ3RV2XWBS

GQ6SHHG,QBV

GQ7S3RVBS

$[LV'DWD

/B&DP6\QF,Q

&

&

&

&75/

GQ6SHHG2XWBV

E(UURU

E$FF

E7S5HFHLYHG

GQ7S7LPH/DJ

E5HVHW

E0DQXDO6\QF

GQ2SHQ3RVBS

GQ6\QF3RVBS

& 6SHHGXQLW

& 3RVXQLW

& 0D[LPXPVSHHG

&

&

&

E6\QF

& 6WDWH

73

&

0D[LPXPUHIHUHQFHVSHHG

& 0LQLPXPWLPHIRUFOXWFKLQ