1 master axis (master shaft), 9400 highline | parameter setting & configuration – Lenze E94AxHE Servo Drives 9400 HighLine (Firmware 01-37) User Manual

Page 338

9400 HighLine | Parameter setting & configuration

TAs for interconnection via electrical shaft

TA "Synchronism with mark synchronisation" | Machine parameters

338

Firmware 1.37 - 09/2006

L

12.3.3.1

Master axis (master shaft)

For scaling and imaging the master value in the application, the machine parameters of

the higher-level drive (master shaft) must be set.

r

Parameter setting: Tab Application parameter Dialog level Overview Synchronism

Master value scaling

Example of determining the machine parameters for the master axis

Note!

When setting (scaling) the electrical shaft, ensure that the ratio and encoder

constants are identical for all drives in the system. The reference to the scaling

of the master drive is sensible.

Parameters

Lenze setting

Value Unit

C03930

Gearbox ratio - numerator

1

C03931

Gearbox ratio - denominator

1

C03932

Feed constant

360.0000 Unit/incr.

C03933

Path units

User-defined

C03934

User-defined path unit

°

C03938

Cycle

360.0000 Unit

C03941

Reference speed

500.0000 Unit/t

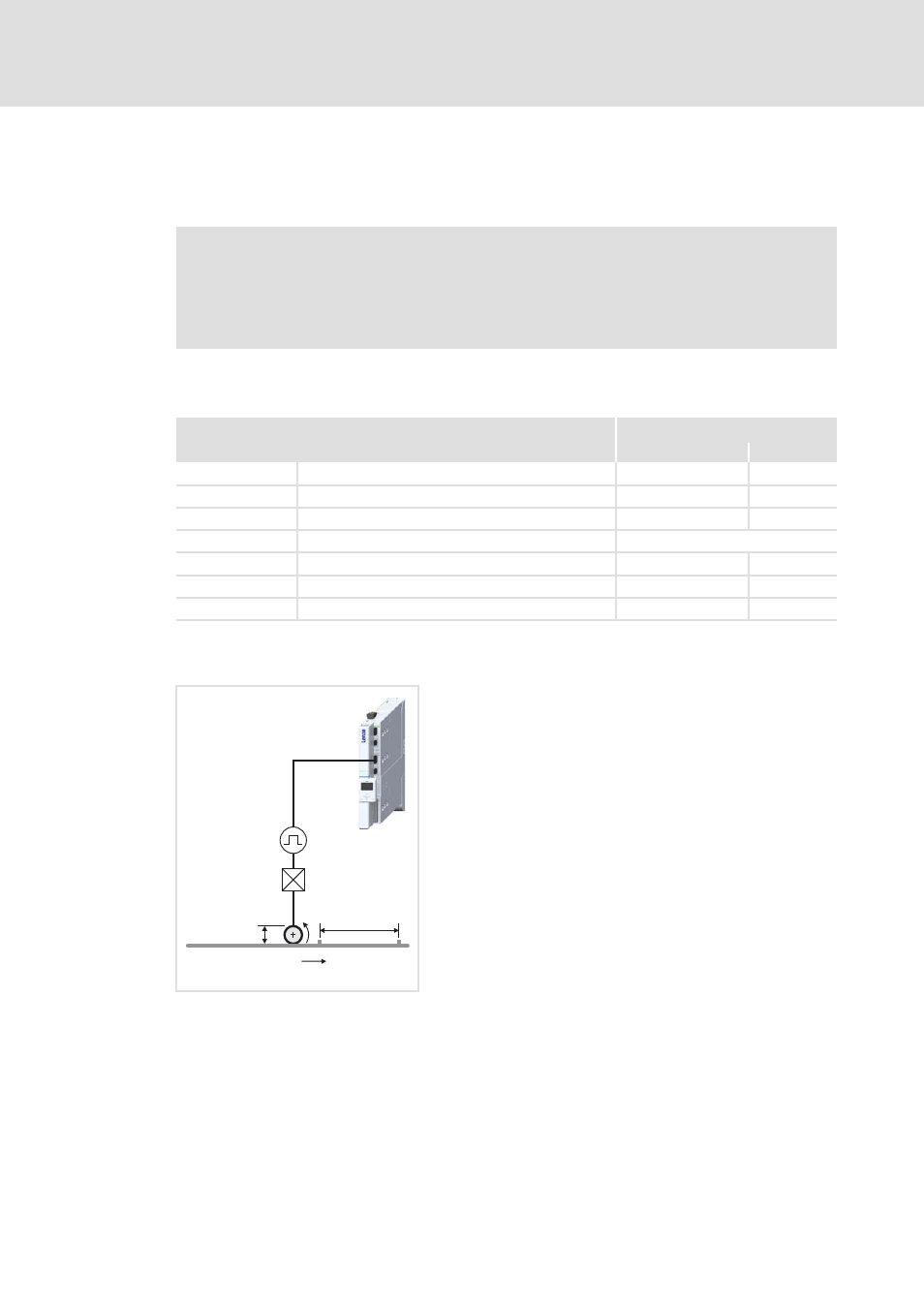

1. Set gearbox ratio for the master value in the form

of a quotient (numerator and denominator):

i

1

= 3.333 = 10/3

– Numerator (C03930) = 10

– Denominator (C03931) = 3

2. Set feed constant (C03932).

– For the master value: Vk = d

1

* π = 471,2389 mm

3. Set the selection "mm" as path unit (C03933).

4. As reference speed (C03941) set the max. machine

speed v

max

= "1000 mm/s".

d

1

i

1

= 150 mm

= 3.333

l

1

= 600 mm

v

max

= 1000 mm/s