1 introduction, 1 synchronisation of the drives via a master angle, 9400 highline | parameter setting & configuration – Lenze E94AxHE Servo Drives 9400 HighLine (Firmware 01-37) User Manual

Page 288

9400 HighLine | Parameter setting & configuration

TAs for interconnection via electrical shaft

Introduction

288

Firmware 1.37 - 09/2006

L

12.1

Introduction

The following subchapters provide information on the electrical shaft.

12.1.1

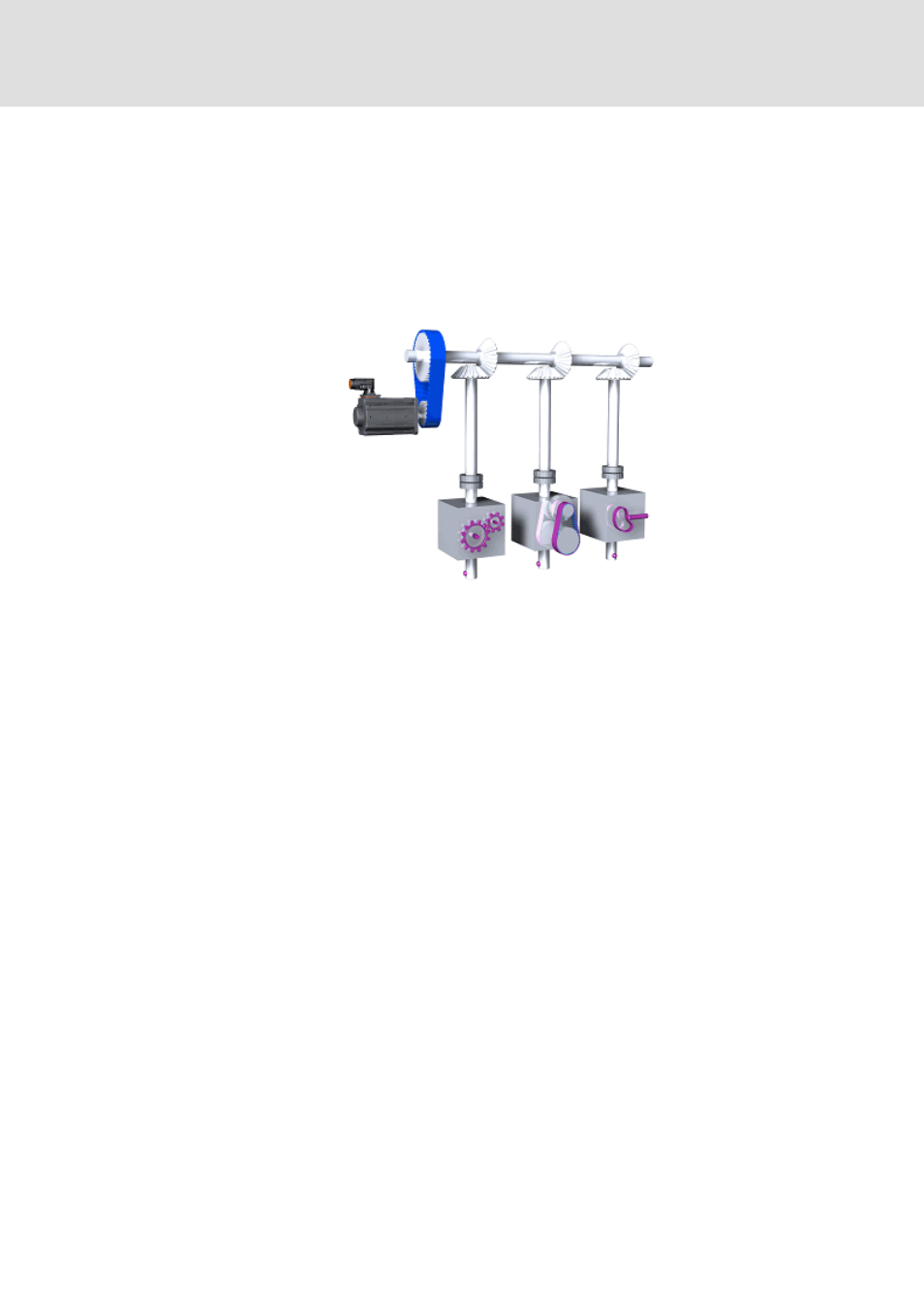

Synchronisation of the drives via a master angle

By coupling the drives via a master angle the positions are firmly allocated to each other

like a mechanical shaft.

r

A drive with a virtual master or a real master (encoder) is able to create the master

angle and transmit this to the other drives which follow this master angle.

Advantages of this type of synchronisation

r

The communication between the drives is very simple. A time-consuming evaluation of

the status signals of each drive and the control signals to be generated from it for each

single drive is not required.

r

Due to the flexible electronics trimming functions can be carried out very easily. Thus,

motion sequences in machines can be easily synchronised and optimised.

r

A variation of the master angle speed changes the number of cycles of the machine.

The drives keep the position allocation.